Wide-strip-shaped semiconductor laser cavity mode selecting method

A semiconductor and laser technology, applied in the laser field, can solve the problems of increasing the instability of the waveguide structure, the beam divergence angle, and the beam quality deterioration, and achieve the effect of improving the beam quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

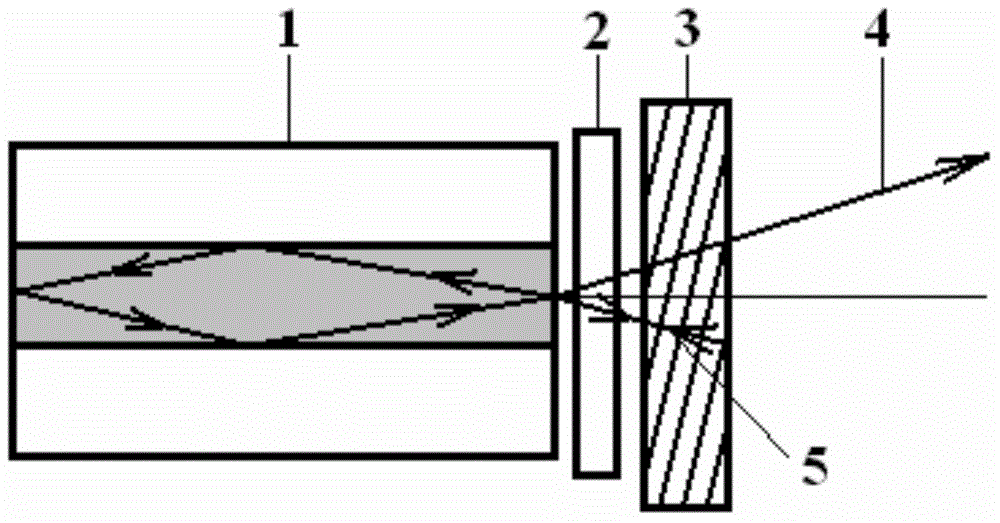

[0006] as attached figure 1 As shown, the rear cavity surface of the wide-strip high-power semiconductor laser chip 1 is coated with a high-reflection film, and the front cavity surface is coated with an anti-reflection film, so that the free-working laser works at a high threshold state. Then, an aspheric cylindrical lens is used to collimate the output beam in the direction of the fast axis, and the beam in the direction of the slow axis remains free to emerge. Then, on the optical axis of the output light beam, place a volume grating 3 whose grating plane normal is inclined to the surface close to the fast axis collimating cylindrical lens 2, whose reflection wavelength is located at the gain spectrum center of the wide strip high-power semiconductor laser chip 1 , to provide efficient spectral feedback. The volume grating 3 is designed for narrow spectrum and narrow angle reflection, and the volume grating feedback beam 5 is fed back to the light-emitting area of the wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com