Active Coupled Inductor Network Boost Converter

A technology of step-up converter and coupled inductor, which is applied in the direction of adjusting electrical variables, converting DC power input to DC power output, and instruments, etc. It can solve the problems of low voltage stress of the main power switch tube, large number of conversion devices, and low conversion efficiency, etc. problem, to achieve the effect of less number of devices, small size and high conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

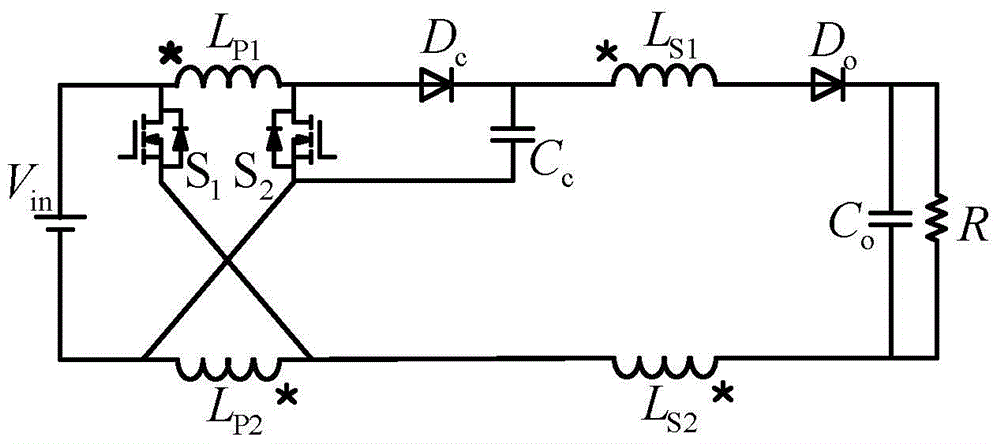

[0019] Specific implementation mode one: refer to figure 1 This embodiment is specifically described. The active coupled inductor network boost converter described in this embodiment includes an X-type active coupled inductor network, a passive lossless clamping circuit, and a filter capacitor C o , rectifier diode D o and resistor R,

[0020] The X-type active coupled inductor network consists of a DC voltage source V in , The primary side of the first coupled inductor L P1 , The secondary side of the first coupled inductor L S1 , The primary side of the second coupled inductor L P2 , The secondary side of the second coupled inductor L S2 , the first power switch tube S 1 and the second power switch S 2 ,

[0021] The passive lossless clamping circuit consists of a clamping diode D c and clamp capacitor C c ,

[0022] The DC voltage source V in The anode of is connected to the first power switch tube S at the same time 1 The anode and primary side of the first c...

specific Embodiment approach 2

[0023] Specific embodiment 2: This embodiment is a further description of the active coupled inductor network boost converter described in specific embodiment 1. In this embodiment, the first power switch tube S 1and the second power switch S 2 Both are MOS tubes or IGBT tubes.

specific Embodiment approach 3

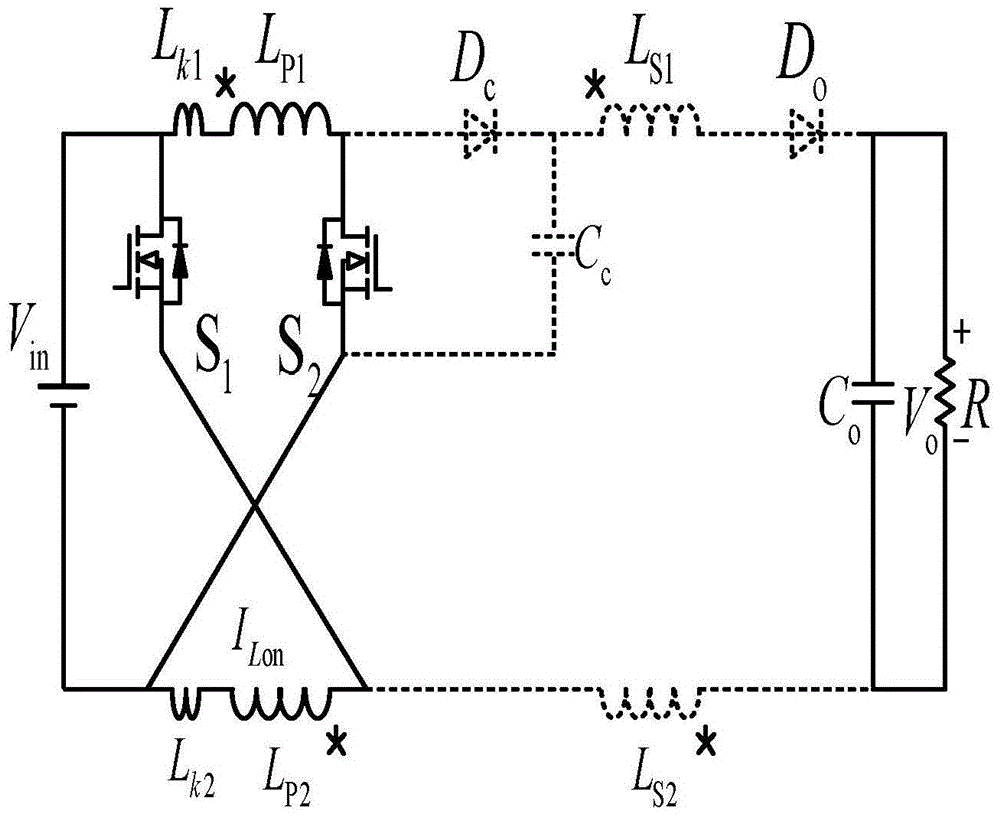

[0024] Specific implementation mode three: refer to Figure 2 to Figure 5 Describe this embodiment in detail. This embodiment is a further description of the active coupled inductor network boost converter described in Embodiment 1. In this embodiment, the working modes of the first coupled inductor and the second coupled inductor are the same , the first coupled inductor and the second coupled inductor are integrated on one magnetic core.

[0025] Operating principle and working process of the present invention are as follows:

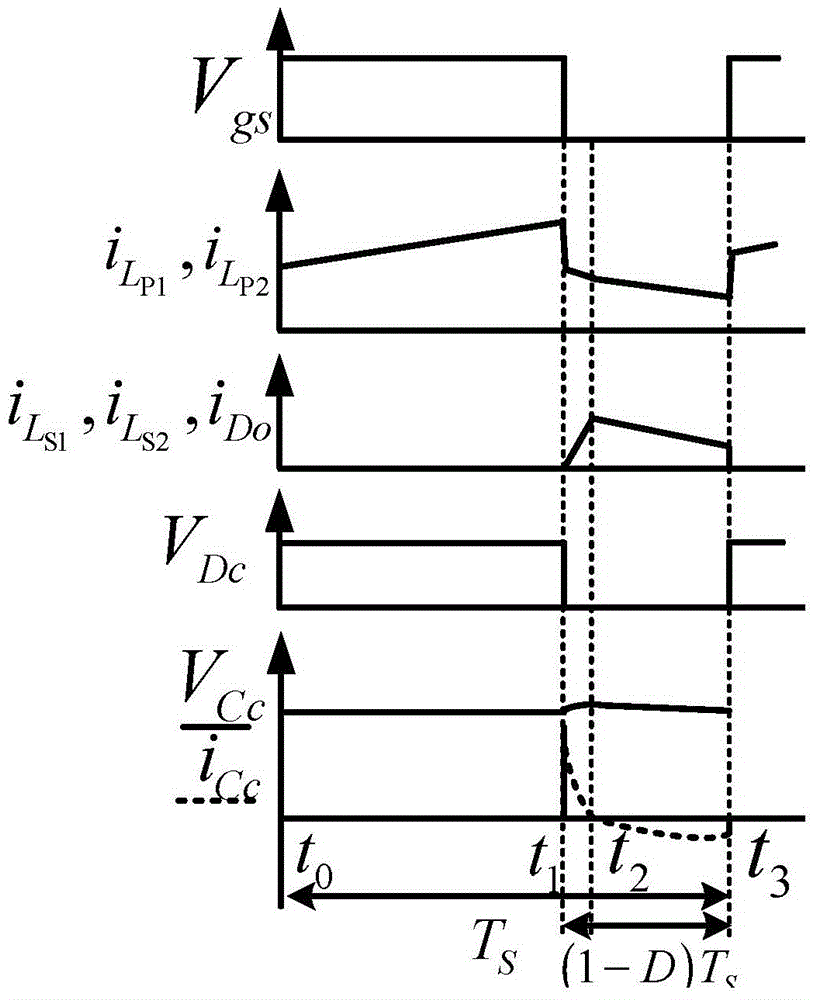

[0026] The active coupled inductance network boost converter of the present invention controls the signal voltage V gs ;The primary current of the first coupled inductor and the second coupled inductor primary current First coupled inductor secondary current Secondary coupled inductor current and the output diode current i Do ; Clamp diode voltage V Dc ; Clamp capacitor voltage V Cc and current i Cc The waveform is as figure 2 As shown,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com