Belt-shaped seedbed stubble clearing device

A cleaning device and root stubble technology, applied in the field of agricultural machinery, can solve the problems of unfavorable seed germination and crop growth, affecting seed germination, emergence, and large soil disturbance, so as to improve the quality of sowing and crop yield, and reduce seed growth The effect of bad, simple mechanism structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

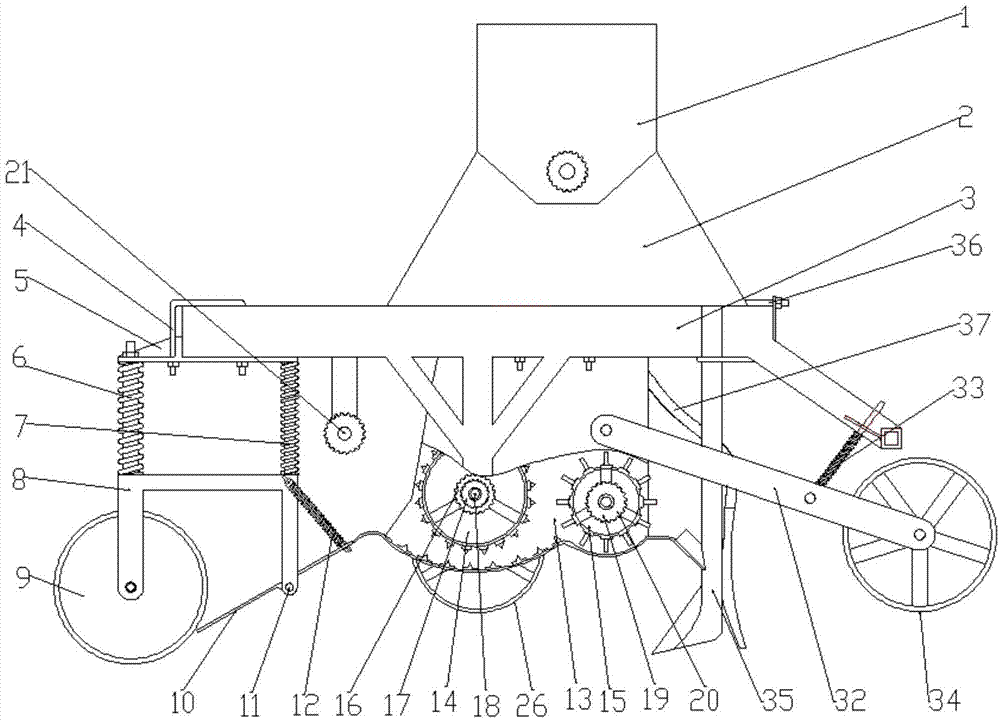

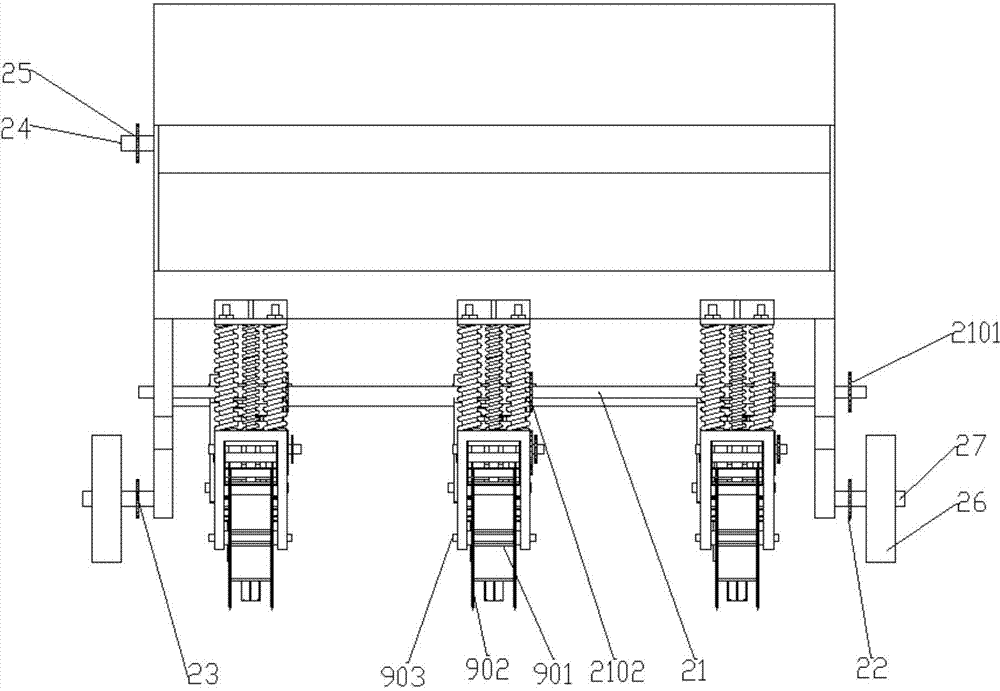

[0036] The invention provides a stubble cleaning device for belt-shaped seed beds. The invention will be further described in detail below in conjunction with the embodiments and accompanying drawings.

[0037] Such as figure 1 , figure 2 with image 3 The front view, left view and rear view of the strip seed bed stubble cleaning device embodiment shown respectively, the strip seed bed stubble cleaning device mainly consists of a soil cutting device and a soil dividing device installed on the frame 3 and a power transmission mechanism.

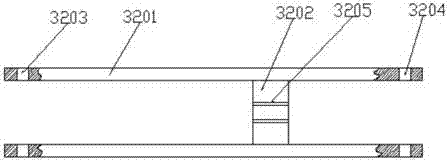

[0038] Such as Figure 4A with Figure 4B Respectively shown frame top view and frame front view, frame 3 is made up of frame front beam 301, frame middle beam 302, frame rear beam 303, frame tail beam 304, frame left beam 305, frame right Beam 306, left tail beam connecting plate 307 and right tail beam connecting plate 308 form a "mesh" frame structure, the front beam 301 of the frame, the middle beam 302 of the frame and the rear beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com