Ionothermal synthesis method of CHA type microporous aluminum phosphate molecular sieve membrane

A technology of aluminum phosphate molecular sieve and molecular sieve, which is applied in the production of molecular sieve and alkali-exchanged phosphate, molecular sieve characteristic silicoaluminophosphate, bulk chemicals, etc. It can solve problems such as potential safety hazards, heavy and complicated coating process, and environmental pollution, and achieve Easy operation, good gas separation and permeability performance, and environment-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

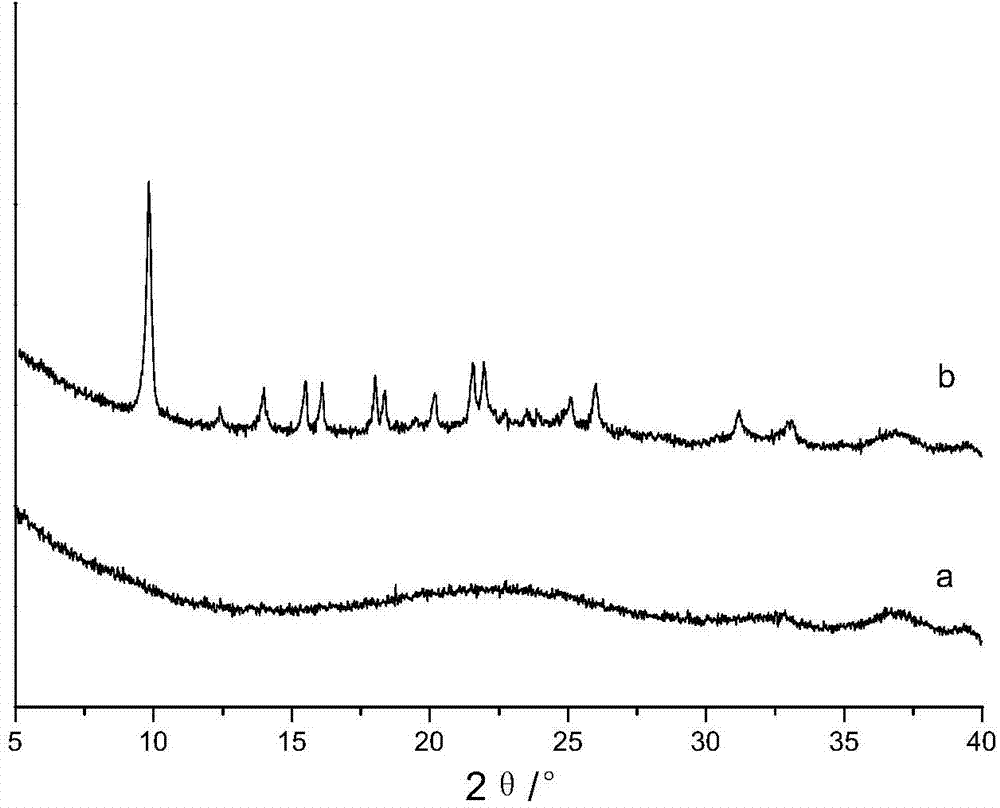

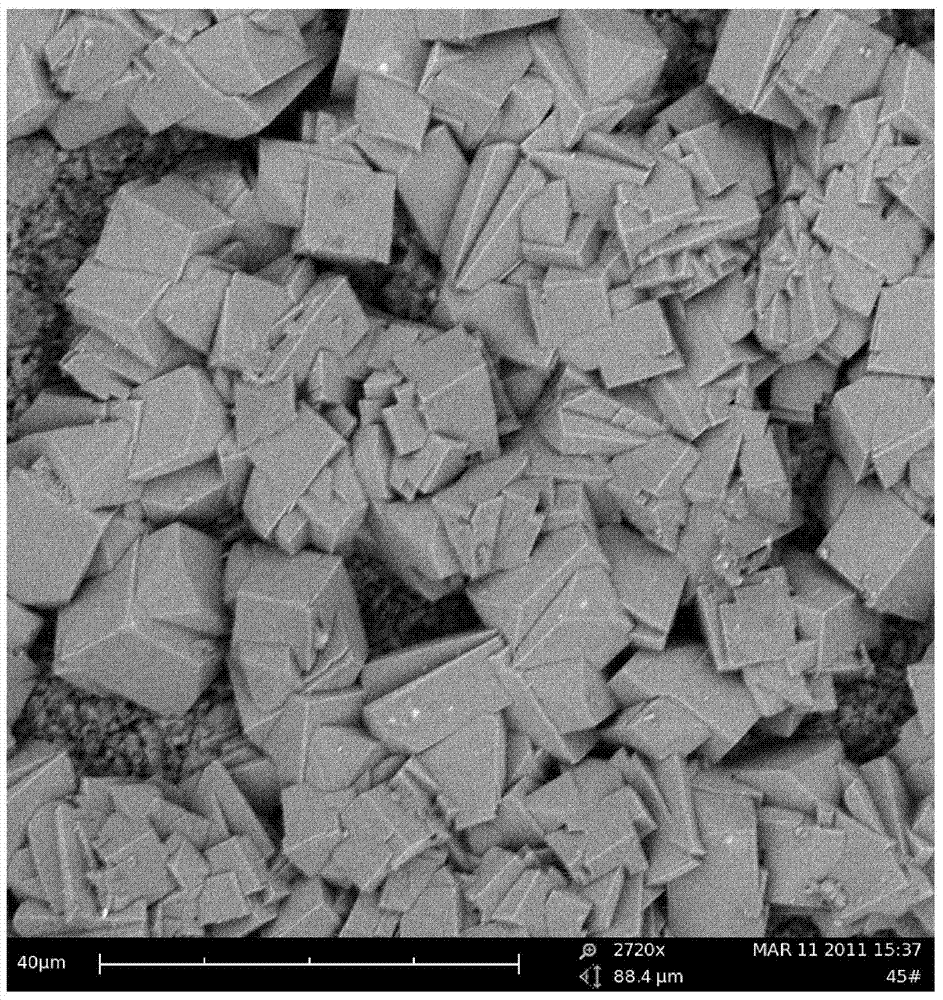

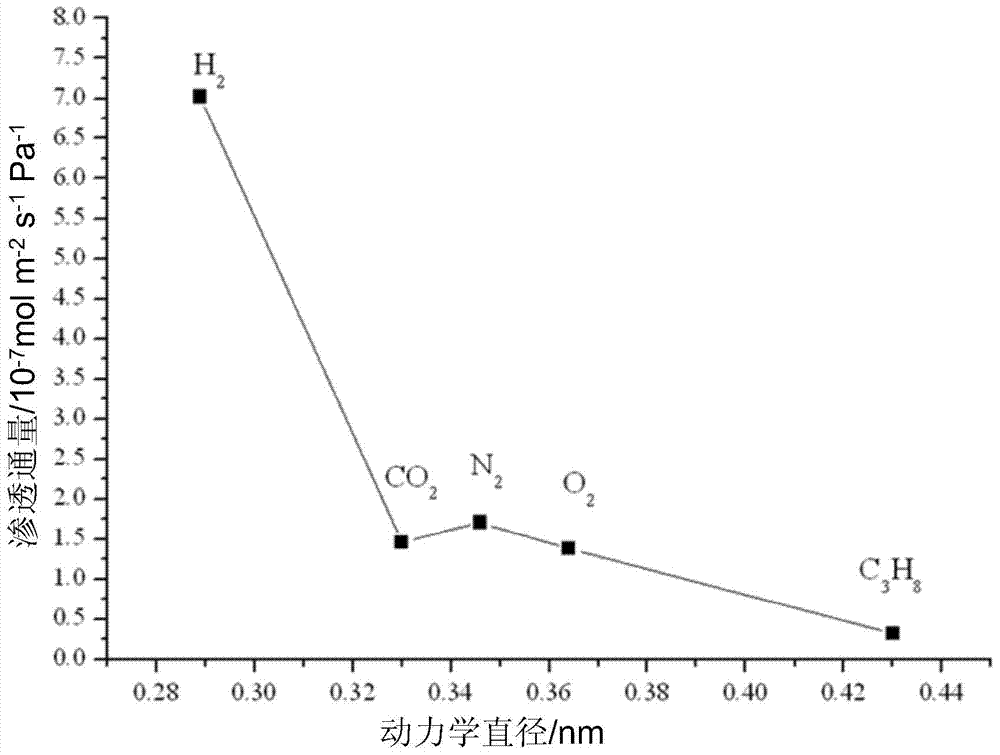

Embodiment 1

[0031] Add 76.4 grams of 1-ethyl-3-methylimidazolium bromide ionic liquid into a 100 ml beaker, heat up to 100°C, evenly add 0.5 grams of hydrofluoric acid with a mass concentration of 40%, stir for 0.5 hours until uniform, and obtain F in mineralizer ionic liquid solution - : The molar ratio of the ionic liquid is 1:40; then the mineralizer ionic liquid solution is poured into the reactor with the δ-alumina carrier placed in advance, and the carrier must be completely immersed in the reaction solution, the support body and the mineralizer The dosage ratio of the ionic liquid solution is 0.5 (cm 2 ·ml -1 surface area of the support), the reactor was heated to 210°C and kept for 1 hour, and then the carrier was taken out; 76.4 grams of 1-ethyl-3-methylimidazolium bromide ionic liquid was added to another 100 ml beaker, and the temperature was raised to 100 ℃, evenly drop 1.15 g of phosphoric acid with a mass concentration of 85% and 0.41 g of N-methylimidazole, and P in the i...

Embodiment 2

[0034] Add 76.4 grams of 1-ethyl-3-methylimidazolium bromide ionic liquid into a 100 milliliter beaker, heat up to 100 ° C, evenly add 0.05 grams of hydrofluoric acid with a mass concentration of 40%, stir for 0.5 hours until uniform, and obtain F in mineralizer ionic liquid solution - : The molar ratio of the ionic liquid is 1:400; then pour the mineralizer ionic liquid solution into the reactor with the δ-alumina carrier placed in advance, pay attention that the carrier must be completely immersed in the reaction solution, the support body and the mineralizer The dosage ratio of the ionic liquid solution is 0.8 (cm 2 ·ml -1 surface area of the support), the reactor was heated to 120°C and kept for 480 hours, and then the carrier was taken out; 76.4 grams of 1-ethyl-3-methylimidazolium bromide ionic liquid was added to another 100 ml beaker, and the temperature was raised to 100 ℃, evenly drop 0.12 g of phosphoric acid with a mass concentration of 85% and 0.21 g of N-meth...

Embodiment 3

[0036] Add 76.4 grams of 1-ethyl-3-methylimidazolium bromide ionic liquid into a 100 ml beaker, heat up to 100° C., evenly add 1.0 grams of hydrofluoric acid with a mass concentration of 40%, stir for 0.5 hours until uniform, and obtain F in mineralizer ionic liquid solution - : The molar ratio of the ionic liquid is 1:20; then pour the mineralizer ionic liquid solution into the reactor with the θ-alumina carrier placed in advance, pay attention that the carrier must be completely immersed in the reaction solution, the support body and the mineralizer The dosage ratio of the ionic liquid solution is 0.4 (cm 2 ·ml -1 surface area of the support body), the reactor was heated to 160°C and kept for 4 hours, and then the carrier was taken out; 76.4 grams of 1-ethyl-3-methylimidazolium bromide ionic liquid was added to another 100 ml beaker, and the temperature was raised to 100 ℃, evenly drop 2.30 grams of phosphoric acid with a mass concentration of 85% and 0.41 grams of N-met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com