Zinc oxide concentrate purifying technology

A zinc oxide and concentrate technology, applied in the direction of zinc oxide/zinc hydroxide, etc., can solve the problems of harsh equipment conditions, poor product uniformity, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1: a kind of zinc oxide concentrate purification process comprises the following steps:

[0051] (1) acid leaching

[0052] Put the zinc oxide concentrate in an acid-resistant container, slowly add concentrated sulfuric acid with a concentration of 80% to control the pH value at 4, stir continuously to fully dissolve the mineral powder; filter after 2 hours to remove the acid-insoluble matter, and keep filtrate;

[0053] (2) Oxidation and iron removal

[0054] Heat the first step filtrate to about 85°C, add H 2 o 2 , stirred at a constant speed for 1 hour; when the solution gradually turned yellow and the reaction was complete, continue heating and boiling for 10 minutes to remove excess H 2 o 2 , suction filtration, remove the yellow-brown floc suspension in the solution, and keep the filtrate;

[0055] (3) Manganese removal

[0056] Add ammonium persulfate precipitant to the filtrate of the second step to carry out precipitation reaction; after the p...

Embodiment 2

[0068] In Example 1, the precipitation agent in the sixth step is respectively Na 2 C 2 o 4 , (NH 4 ) 2 CO 3 , in urea and ammoniacal liquor, sodium hydroxide, the experimental result obtained is as follows:

[0069] Table 2 Morphology of calcined products obtained with different precipitants

[0070]

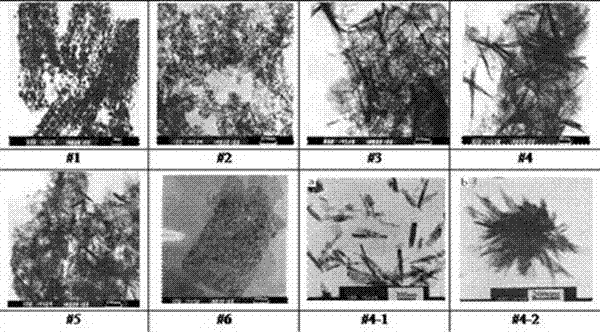

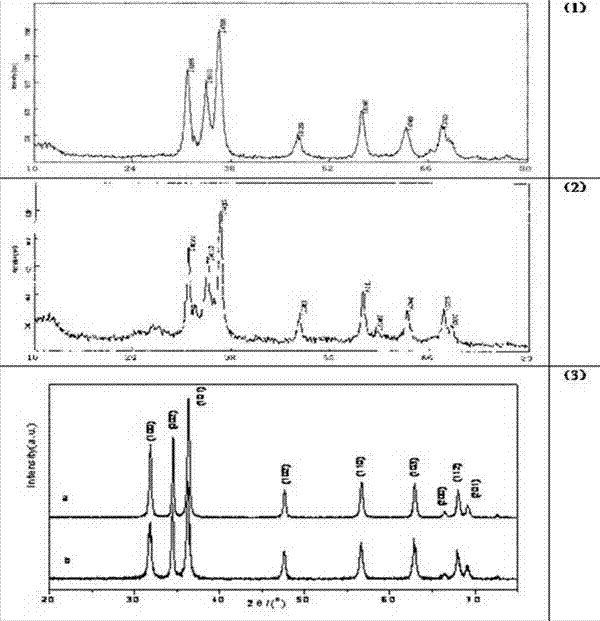

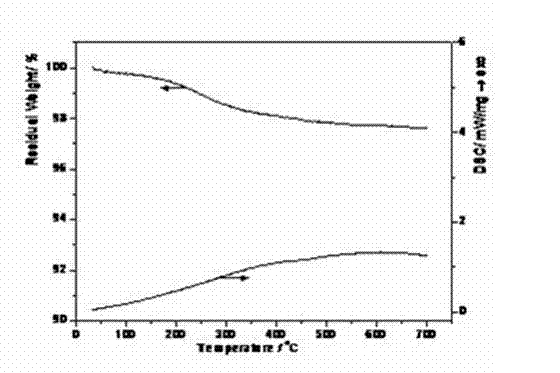

[0071] It can be clearly seen from Table 2 that when Na 2 C 2 o 4 When used as a precipitant, the final calcined products are all spherical particles. to (NH 4 ) 2 CO 3 When , the obtained product is mainly spherical particles, only a few needle-like ZnO whiskers. When using urea / ammonia water, more acicular ZnO whiskers can be produced. Only when sodium hydroxide is used as a precipitating agent, the final product obtained is relatively pure acicular or multi-acicular ZnO whiskers.

[0072] In addition, choose sodium hydroxide as precipitant, by changing ZnSO 4 Concentration, and fix it and the initial concentration ratio of precipitant solution, the morpholog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com