Room-temperature vulcanized silicone rubber adhesive and preparation method thereof

A technology of room temperature vulcanization and silicone rubber, applied in the direction of adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of low light transmittance, achieve good storage performance, excellent mechanical properties, and good light transmittance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

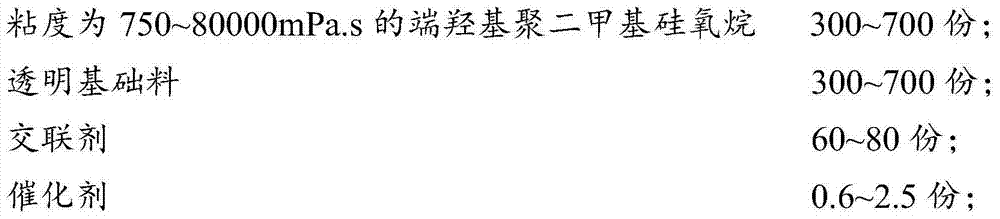

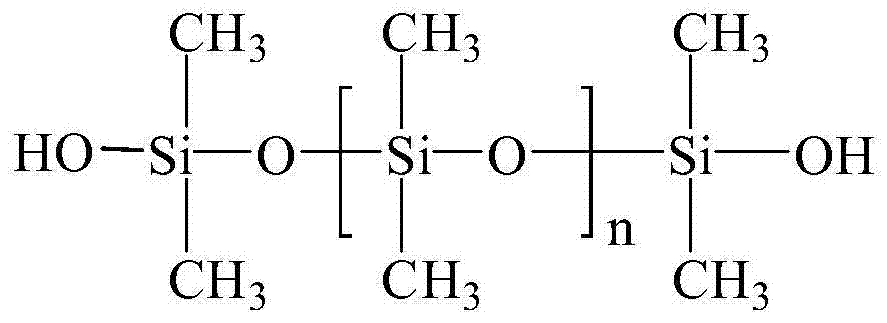

Method used

Image

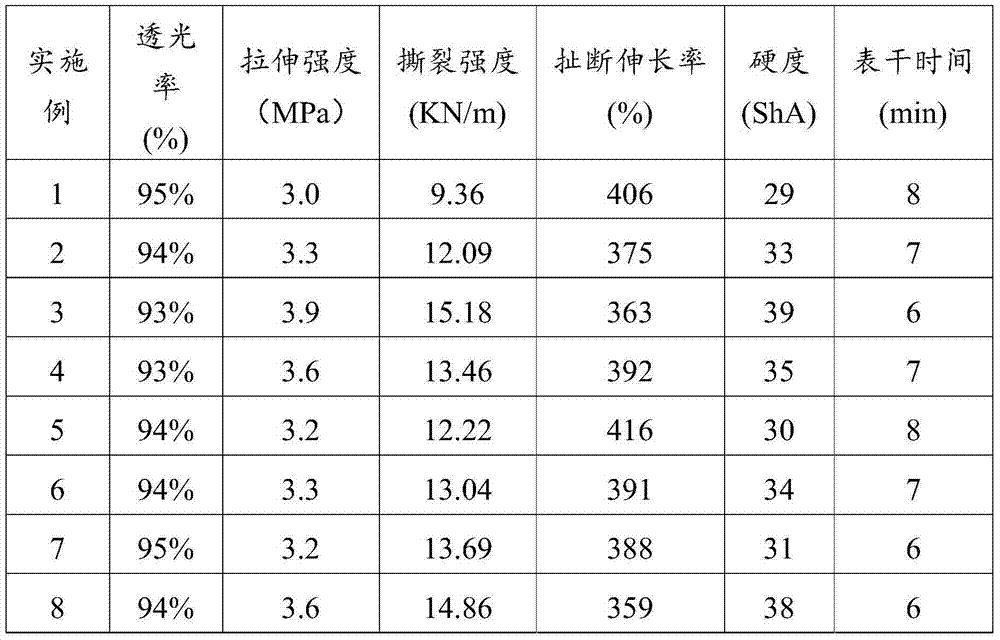

Examples

preparation example 1

[0028] The transparent base material of the present invention is made by the following steps:

[0029] (1), combine 100 parts of hydroxyl terminated polydimethylsiloxane with a viscosity of 5000-50000mPa.s, 5-10 parts of hexamethyldisilazane, 1-2.5 parts of distilled water and 15-25 parts of The fumed silica is added to the vacuum kneader, and the above-mentioned materials are heated to 90~150℃ and then vacuum kneaded for 4~6 hours;

[0030] (2), heat the material after vacuum kneading to 150~180 ℃, vacuumize for 2~6 hours, remove low molecular weight, water content and excess hexamethyldisilazane, cool it for later use, thereby making transparent base material.

Embodiment 1

[0032] The room temperature vulcanization silicone rubber adhesive of the present invention is made by the following steps:

[0033] (1), add 333 parts of transparent base materials prepared in Preparation Example 1 and 667 parts of hydroxyl-terminated polydimethylsiloxane with a viscosity of 5000 mPa.s into the reaction kettle, start stirring, and the stirring speed is 300 to 500 rpm / min, set the oil temperature of the reaction kettle to be 140~160 ℃, stir and heat up;

[0034] (2), when the material temperature rises to 140~160 ℃, constant temperature stirring for 2 hours;

[0035] (3) After the constant temperature stirring is completed, vacuum dehydration treatment is carried out, the vacuum pressure value is -0.09~-0.1MPa, and after stirring and dehydration under vacuum for 2 hours, the material is cooled to room temperature to obtain the first mixture;

[0036] (4), in the anhydrous state at room temperature, add 72 parts of a mixture of methyl triacetoxy silane and et...

Embodiment 2

[0039] The room temperature vulcanization silicone rubber adhesive of the present invention is made by the following steps:

[0040] (1), add 466.7 parts of transparent base material and 533.3 parts of hydroxyl-terminated polydimethylsiloxane with viscosity of 1500mPa.s obtained in Preparation Example 1 into the reaction kettle, start stirring, and the stirring speed is 300~500 rpm / min, set the oil temperature of the reaction kettle to be 140~160 ℃, stir and heat up;

[0041] (2), when the material temperature rises to 140~160 ℃, constant temperature stirring for 2 hours;

[0042] (3) After the constant temperature stirring is completed, vacuum dehydration treatment is carried out, the vacuum pressure value is -0.09~-0.1MPa, and after stirring and dehydration under vacuum for 2 hours, the material is cooled to room temperature to obtain the first mixture;

[0043] (4), in the anhydrous state at room temperature, add 68.8 parts of a mixture of methyl triacetoxy silane and eth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com