Processing method of novel preserved black potatoes

A processing method and technology of black potatoes, applied in the confectionary industry, confectionery, food science, etc., can solve problems such as blanks, and achieve the effects of attractive color, high economic benefits, and unique flavor quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

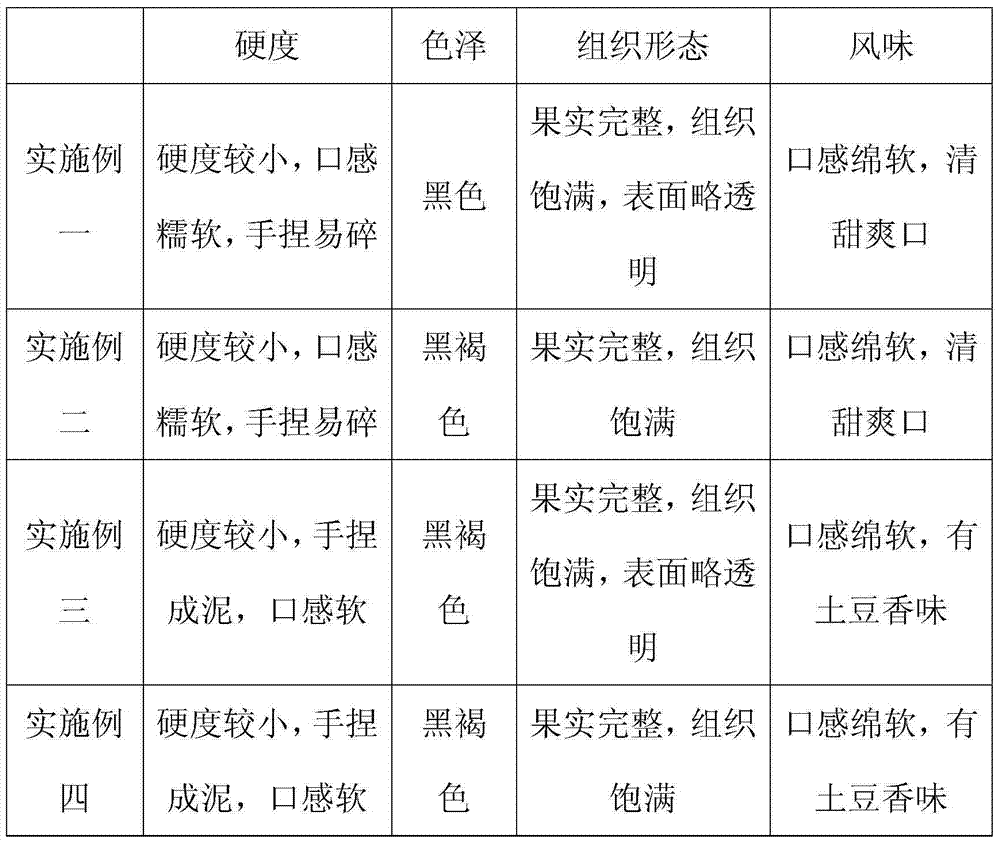

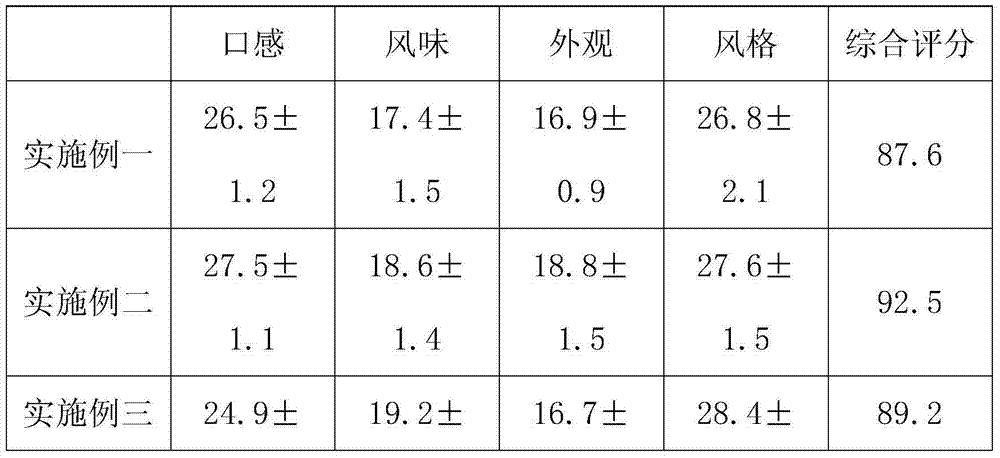

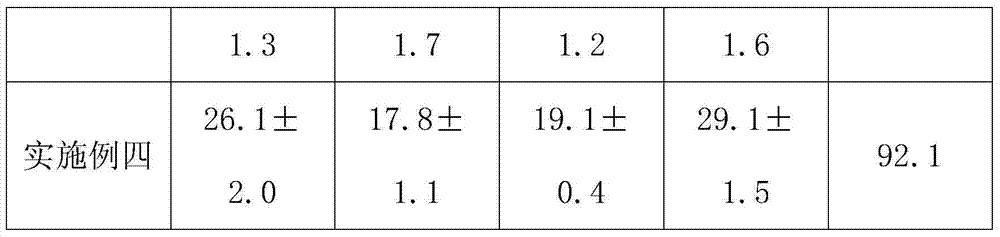

Examples

Embodiment 1

[0033] A processing method of novel black potato preserves, comprising the following steps:

[0034] (1) Selection and cleaning of raw materials:

[0035] Choose black potatoes with a single potato weight of 120-140 grams, full appearance, uniform size, complete skin, no cracks, no insect eyes, and no mildew as raw materials, put them into an ozone cleaning machine, and fully wash;

[0036] (2) Soaking and cooking:

[0037] Soak black potatoes in sodium bicarbonate solution (pH 8.0-8.1), adjust the water temperature with the soaking time, the water temperature is 27°C for the 0th-5th hour, 23°C for the 6th-9th hour, and 23°C for the 10th-15th hour hours, the water temperature is 7°C;

[0038] After soaking, rinse with citric acid solution (pH 6.4-6.5), and cook at 100°C for 15 minutes;

[0039] (3) Sugar infiltration and sugar extraction:

[0040] The sugar infiltration temperature is 50°C, and the concentration of the sugar solution is 35%, 46%, and 63% for three times, a...

Embodiment 2

[0046] A processing method of novel black potato preserves, comprising the following steps:

[0047] (1) Selection and cleaning of raw materials:

[0048] Choose black potatoes with a single potato weight of 120-140 grams, full appearance, uniform size, complete skin, no cracks, no insect eyes, and no mildew as raw materials, put them into an ozone cleaning machine, and fully wash;

[0049] (2) Soaking and cooking:

[0050] Soak black potatoes in sodium bicarbonate solution (pH 8.0-8.1), adjust the water temperature with the soaking time, the water temperature is 30°C for the 0th-5th hour, 25°C for the 6th-9th hour, and 25°C for the 10th-15th hour hours, the water temperature is 9°C;

[0051] After soaking, rinse with citric acid solution (pH 6.6-6.7), and cook at 100°C for 17 minutes;

[0052] (3) Sugar infiltration and sugar extraction:

[0053] The sugar infiltration temperature is 50°C, and the concentration of the sugar solution is 35%, 46%, and 63% for three times, a...

Embodiment 3

[0059] A processing method of novel black potato preserves, comprising the following steps:

[0060] (1) Selection and cleaning of raw materials:

[0061] Choose black potatoes with a single potato weight of 120-140 grams, full appearance, uniform size, complete skin, no cracks, no insect eyes, and no mildew as raw materials, put them into an ozone cleaning machine, and fully wash;

[0062] (2) Soaking and cooking:

[0063] Soak black potatoes in sodium bicarbonate solution (pH 8.0-8.1), adjust the water temperature with the soaking time, the water temperature is 28°C for the 0th-5th hour, 24°C for the 6th-9th hour, and 24°C for the 10th-15th hour hours, the water temperature is 8°C;

[0064] After soaking, rinse with citric acid solution (pH 6.4-6.5), and cook at 100°C for 15 minutes;

[0065] (3) Sugar infiltration and sugar extraction:

[0066] The sugar infiltration temperature is 50°C, and the concentration of the sugar solution is 35%, 46%, and 63% for three times, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com