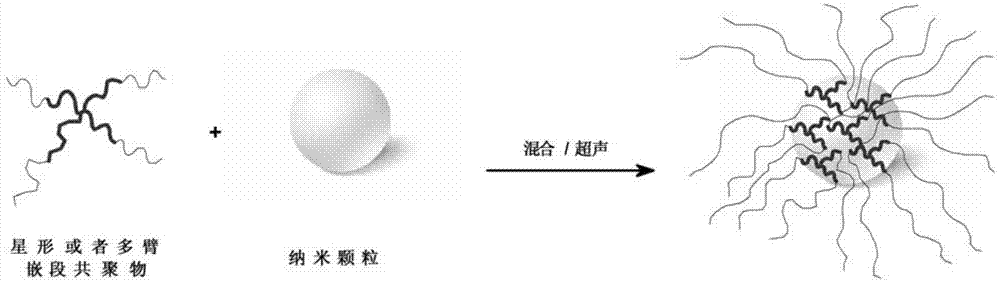

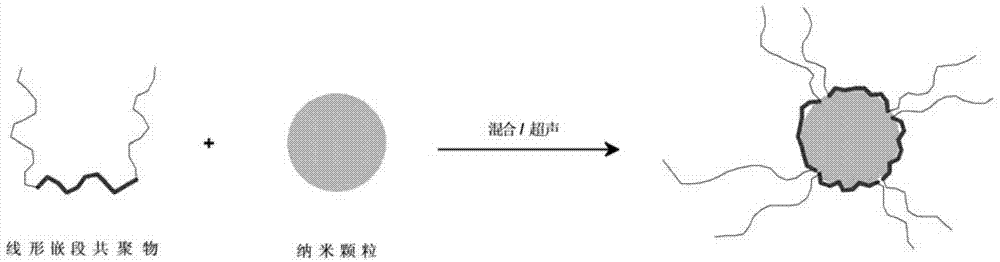

Application of star-shaped/multi-arm block copolymers in preparation of mixture containing nano-particles

A block copolymer and nanoparticle technology, applied in the field of materials science, can solve problems such as limited application scope, limited application, instability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

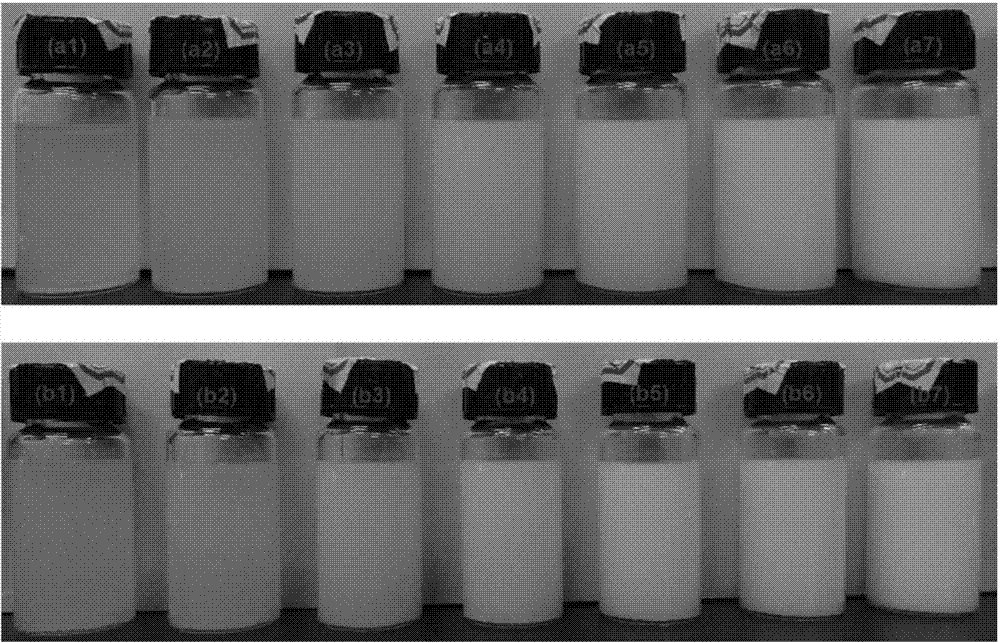

Embodiment 1

[0146] Embodiment 1: the synthesis of isobutylene-propylene glycol-isobutylene three-arm block copolymer

[0147]173.25g (excessive 5%) polyisobutylene succinic anhydride (PIBSA) (molecular weight is 1100g / mol) and 200ml normal hexane are dissolved in the there-necked flask of 500ml, then under nitrogen atmosphere, under continuous stirring condition, the there-necked flask is placed In an oil bath at 60°C, use a 150ml constant pressure dropping funnel to dissolve 22.0g of polyetheramine T-403 (molecular weight: 440g / mol, three-arm polymer, each arm has an amino group at the end of the molecular chain.) Dissolve in 100ml In acetone, when the temperature of the solution in the three-necked flask is stable at 60°C, add the polyetheramine T-403 solution dropwise into the there-necked flask, and stir the resulting solution at 60°C for at least 8 hours until the solution turns yellow. White emulsion, the solvent was removed by vacuum rotary evaporation, and a viscous light yellow l...

Embodiment 2

[0148] Embodiment 2: the synthesis of isobutylene-pentaerythritol propoxylate-isobutylene four-arm block copolymer

[0149] 115.5g (excessive 5%) polyisobutylene succinic anhydride (PIBSA) (molecular weight is 1100g / mol) and 200ml N, N-dimethylformamide are dissolved in the there-necked flask of 500ml, then under nitrogen atmosphere, continuous stirring condition 10.65g of polypentaerythritol propoxylate (molecular weight: 426g / mol, CAS number: 9051-49-4, four-armed polymer, Each arm has a hydroxyl group at the end of the molecular chain.) was dissolved in 80ml N, N-dimethylformamide, and when the temperature of the solution in the there-necked flask was stabilized at 100°C, the polypentaerythritol propoxylate solution was added dropwise Add it into a three-neck flask, and stir the resulting solution at 100°C for at least 24 hours until the solution turns into a yellow-white emulsion. The solvent is removed by vacuum rotary evaporation to obtain a viscous light yellow liquid p...

Embodiment 3

[0150] Embodiment 3: the synthesis of isobutylene-pentaerythritol propoxylate-isobutylene radial block copolymer

[0151] 115.5g (excessive 5%) polyisobutylene succinic anhydride (PIBSA) (molecular weight is 1100g / mol) and 200ml N, N-dimethylformamide are dissolved in the there-necked flask of 500ml, then under nitrogen atmosphere, continuous stirring condition Next, place the three-neck flask in an oil bath at 100°C, and use a 150ml constant pressure dropping funnel to add 7.86g of polypentaerythritol propoxylate (molecular weight: 629g / mol, CAS number: 9051-49-4, star-shaped polymer, Contain eight molecular chain branches, the end of each molecular chain branch has a hydroxyl group.) Dissolve in 80ml N, N-dimethylformamide, when the temperature of the solution in the there-necked flask is stable at 100°C, the polypentaerythritol The propoxylate solution was added dropwise into a three-necked flask, and the resulting solution was stirred at 100°C for at least 24 hours until t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com