Inductive magnetoelectric biochemical reaction system and its application

A biochemical reaction, inductive technology, applied in the direction of enzyme production/bioreactor, bioreactor/fermenter combination, biochemical instruments, etc., can solve the problem of single control parameters and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0094] The following takes the preparation of glutinous rice hydroxypropyl starch by alkaline method as an example to further illustrate the application of the induction magnetoelectric biochemical reaction system in the auxiliary modification of natural polymer raw materials.

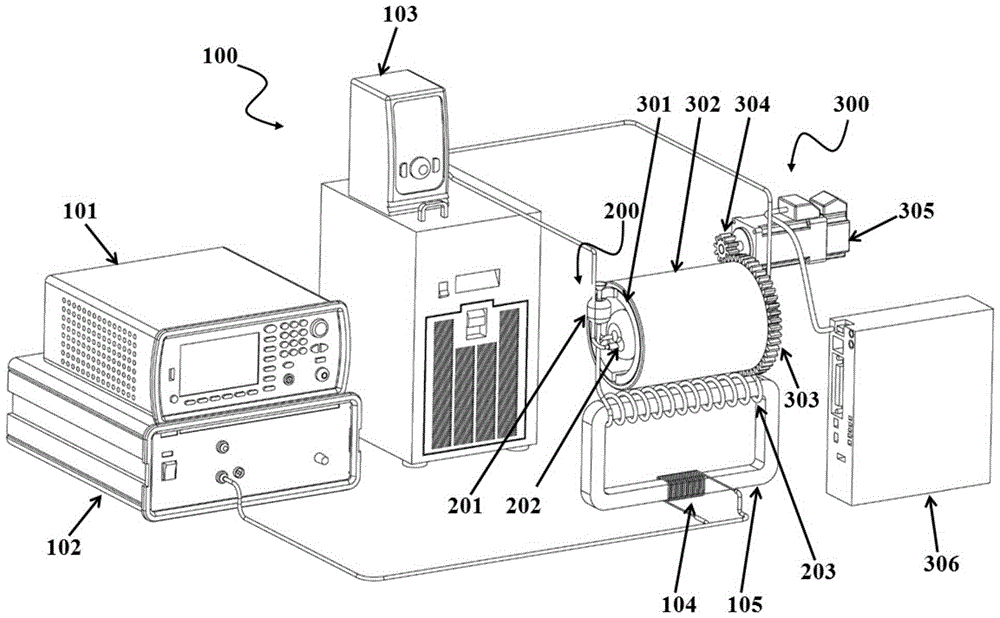

[0095] Such as Figure 1 ~ Figure 4 As shown, in this embodiment, the present invention provides an inductive magnetoelectric biochemical reaction system, which includes a reaction system device chain 100 , a reaction unit 200 , and a rotating magnetic field unit 300 .

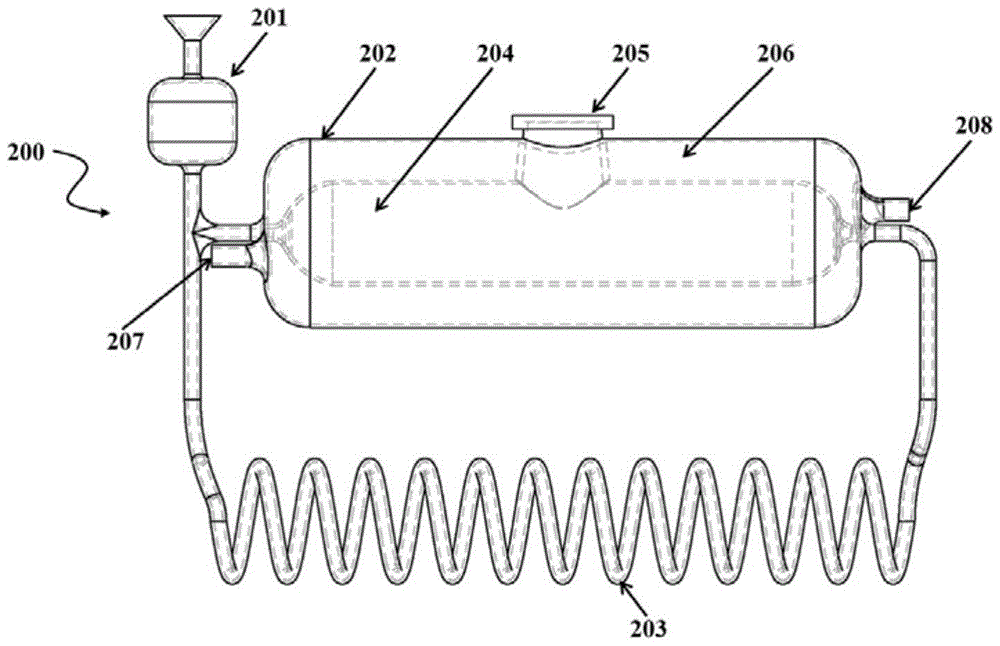

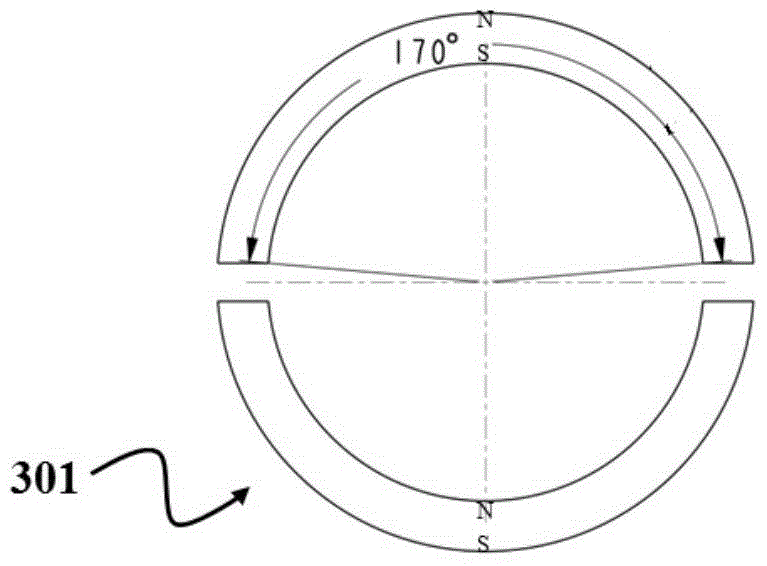

[0096] Among them, refer to figure 1 , the reaction system device chain 100 includes a signal generator 101, a power amplifier 102, a constant temperature circulating water bath 103, a reaction unit 200, a secondary feed port 201 contained in the reaction unit 200, a reaction chamber 202, and a glass spring contained in the reaction chamber 203, rotating magnetic field unit 300, two 170° NdFeB magnetic tiles 301 opposite to each other...

Embodiment 2

[0105] Utilizing the inductive magnetoelectric biochemical reaction system described in Example 1, taking the auxiliary enzymatic hydrolysis of natural polymer raw materials as an example, the method of using the system is further described.

[0106] The system is used to carry out auxiliary enzymatic hydrolysis of cornstarch to prepare oil-absorbing cornstarch, which includes the following steps:

[0107] Step 1: Take 15g of cornstarch in a flask, add 50g of distilled water, mix and shake well to obtain a starch emulsion, add 1mol / L disodium hydrogen phosphate-citric acid buffer, adjust the pH of the starch emulsion to 4.0, and pre- Heat stirring for 15 minutes;

[0108] Step 2: Take the above-mentioned starch emulsion with pH=4 and pour it into the secondary feed port 201 and fill it with the glass spring 203, then the feed liquid enters the reactant container 204, and then take 0.3g starch glucoamylase powder, the enzyme activity is 100,000 units , from the main feed port ...

Embodiment 3

[0114] Utilizing the inductive magnetoelectric biochemical reaction system described in Example 1, taking the auxiliary acid hydrolysis of natural polymer raw materials as an example, the method of using the system is further described.

[0115]Utilize this system to carry out auxiliary hydrochloric acid hydrolysis to cellulose to prepare reducing sugar, it comprises the following steps:

[0116] Step 1: Take 0.5g of cellulose powder in a beaker, add 50g of distilled water, mix and shake well, add 8mL of hydrochloric acid solution with a mass fraction of 36%, and stir evenly;

[0117] Step 2: pour the above-mentioned reactant from the secondary feeding port 201, fill the glass spring 203, and then enter the reactant container 204;

[0118] Step 3: Turn on the signal generator 101 to select a custom waveform and set the voltage and cycle such as Figure 7 shown, where t 0 =0s,t 1 =0.003s,t 2 = 0.006s, t 3 =0.009s,t 4 = 0.011s,t 5 = 0.014s,t 6 = 0.018s,t 7 =0.02s, the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com