A multi-stage induction continuous flow magnetoelectric machining device and its application

A processing device and inductive technology, applied in the direction of transformer/inductor magnetic core, circuit, inductor, etc., can solve the problems of electrode material material leakage, ion polarization, etc., achieve simple operation, improve work efficiency, and avoid ion Effects of Polarization and Electrochemical Reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Embodiment 1: Efficient acid hydrolysis of wheat bran

[0068] Taking the high-efficiency acid hydrolysis of wheat bran to prepare reducing sugar as an example, the application of multi-stage induction continuous flow magnetoelectric processing device in the hydrolysis reaction of natural polymer raw materials is further explained.

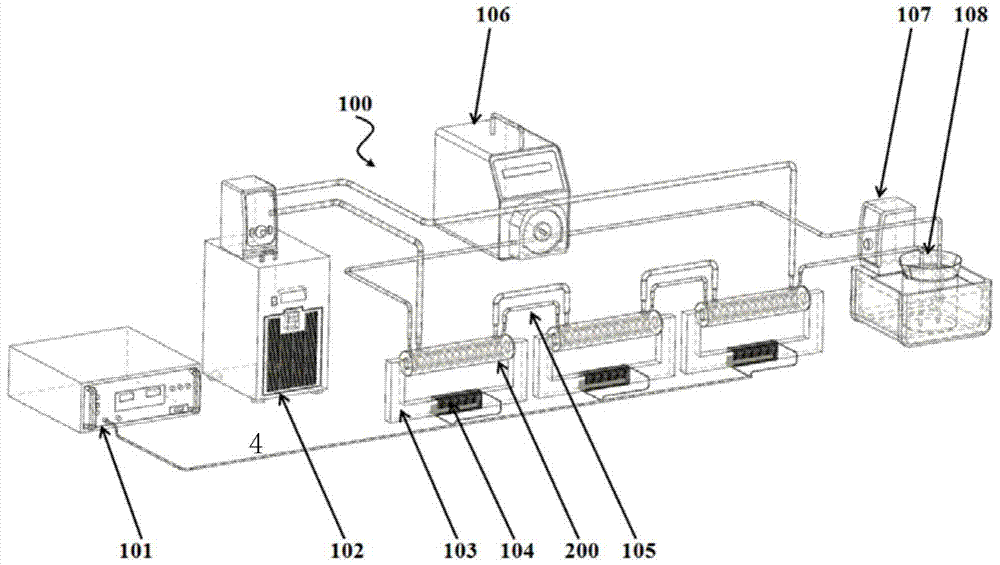

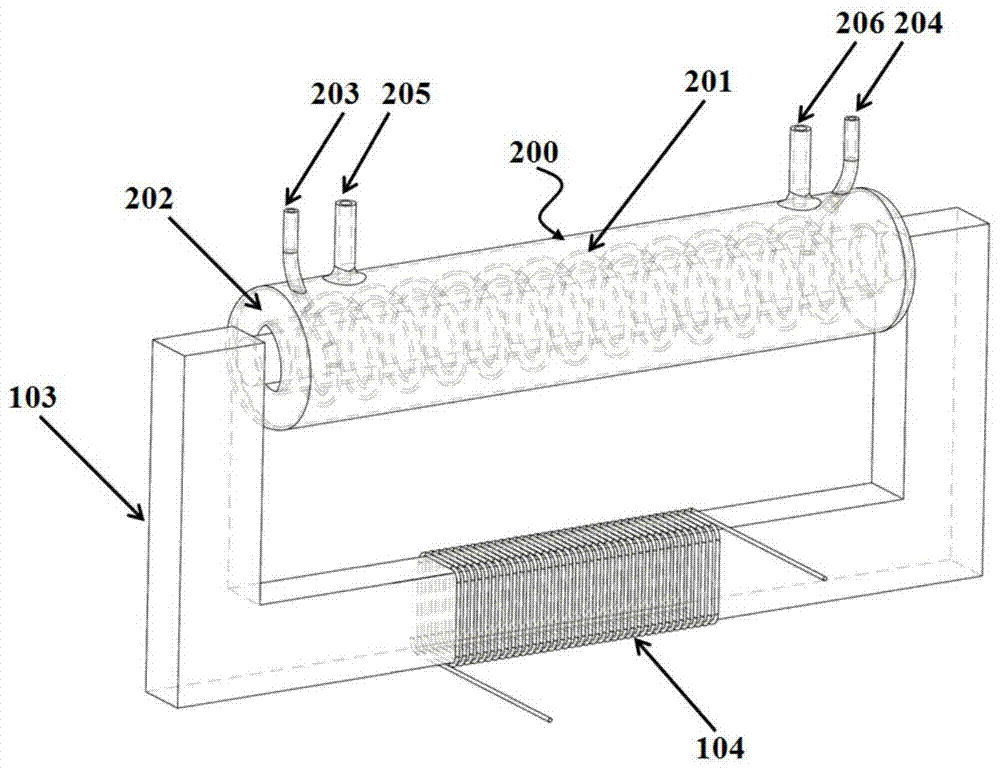

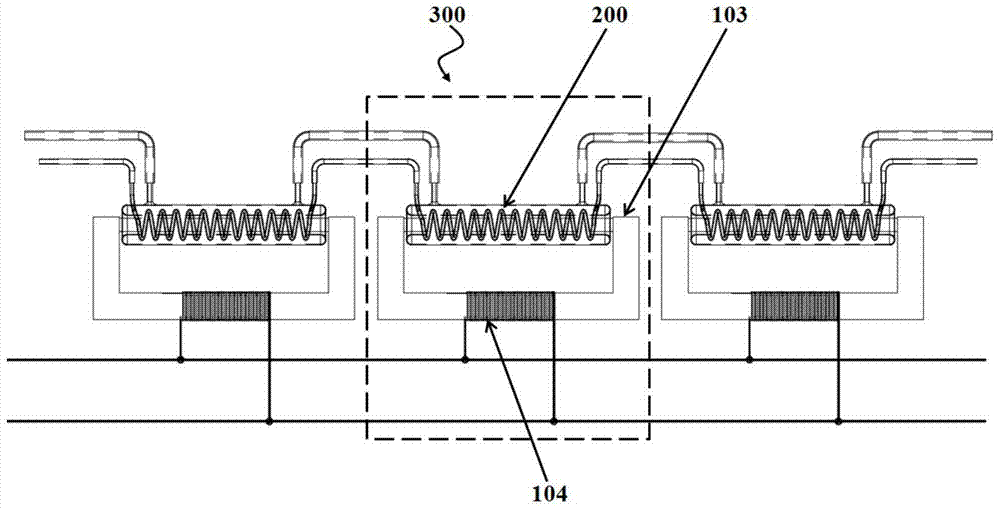

[0069] like Figure 1 to Figure 4 As shown, in this embodiment, the present invention provides a multi-stage induction continuous flow magnetoelectric processing device, which includes a processing device chain 100, an induced voltage cavity 200, an induction unit 300, and a device processing equivalent circuit diagram 400 .

[0070] Among them, refer to figure 1 , the processing device chain 100 includes a high frequency power supply 101, a constant temperature circulating bath 102, a ferrite closed iron core 103, a primary coil 104, an induced voltage cavity 200, an acid and alkali resistant high temperature resistant silicone tube 105,...

Embodiment 2

[0081] Example 2: Efficient extraction of pineapple pomace pectin

[0082] Using the multi-stage induction continuous flow magnetoelectric processing device described in Example 1, taking the auxiliary extraction of natural products as an example, the method of using the system is further described. It includes the following steps:

[0083] Step 1: Take 500g of pineapple peel, put it into a 10L plastic cup 108 after beating, add 8L of distilled water, mix and shake well, stir in a constant temperature bath 107 at 55°C for 20min to preheat, and at the same time slowly add 1L of hydrochloric acid solution with a concentration of 6.5%. Stir for another 5 minutes;

[0084] Step 2: Turn on the peristaltic pump 106 to ensure that the feed liquid fills the glass springs 201 of all induction units, and start to circulate and flow with a volume flow rate of 50mL / s, that is, the pineapple peel dregs feed liquid is fed from the feed port of each induction voltage chamber 200 203 flows ...

Embodiment 3

[0088] Embodiment 3: preparation of corn porous starch

[0089] Using the multi-stage induction continuous flow magnetoelectric processing device described in Example 1, taking the modification of natural polymer compounds as an example, the method of using the system is further described. It includes the following steps:

[0090] Step 1: Put 600g of cornstarch into a 15L plastic cup, add 10L of distilled water, mix and shake well to obtain a starch emulsion, add 5% hydrochloric acid solution, adjust the pH of the starch emulsion to 3.7, preheat and stir at 40°C for 5 minutes;

[0091] Step 2: Turn on the peristaltic pump 106 to ensure that the feed liquid fills the glass springs 201 of all induction units, and start to circulate and flow with a volume flow rate of 500 μL / s, that is, the starch emulsion liquid is fed from the feed port 203 of each induction voltage chamber 200 Flow in, then flow out from its discharge port 204, and enter the next induced voltage chamber 200, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| oil absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com