Method for treatment of molecular sieve by fluorine-containing alkaline medium

An alkaline medium and molecular sieve technology, applied in the direction of mercerized crystalline aluminum silicate zeolite, crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminum silicate zeolite, etc. Dealing with problems such as limited adjustability of the method and enlarged secondary hole diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

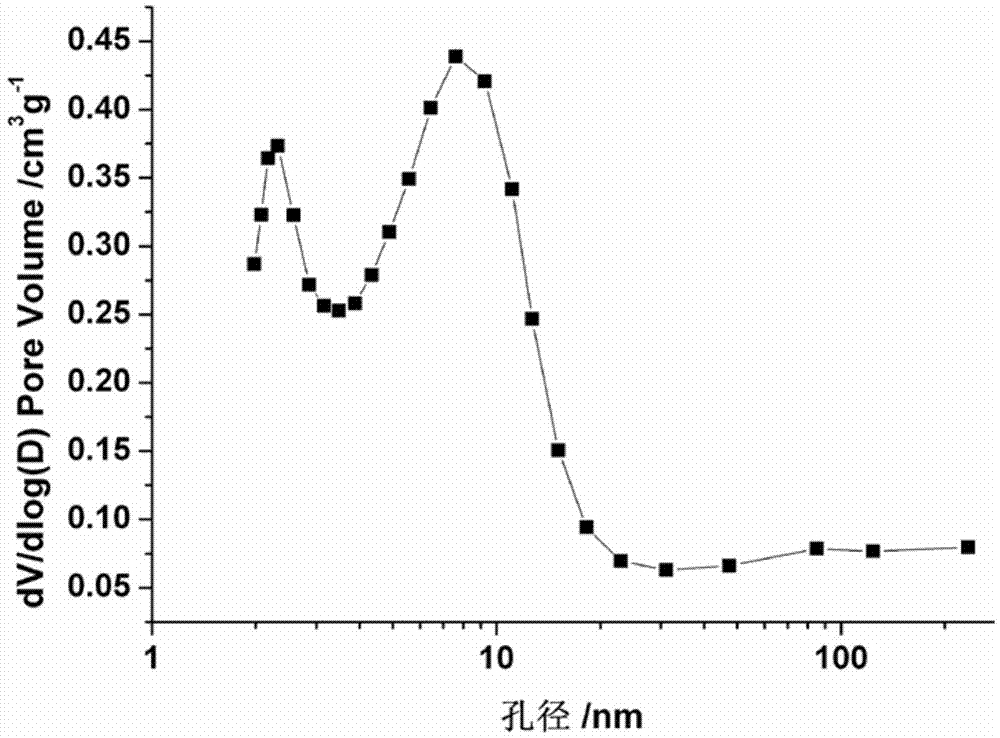

[0025] Get 10g ZSM-5 molecular sieve (Si / Al=40, Na 2 O content 4 In solution F, magnetically stir at 60°C for 35 minutes, then filter and wash until neutral, dry at 120°C for 12 hours, and then bake in a muffle furnace at 550°C for 3 hours. Add the obtained molecular sieves to 0.8 mol / L ammonium nitrate solution, the solid-to-liquid ratio is 1:20, magnetically stir at 85°C for 2 hours, then filter and wash, dry at 120°C for 12 hours, and then place in a muffle furnace Calcined at 550°C for 6 hours, designated as sample A.

Embodiment 2

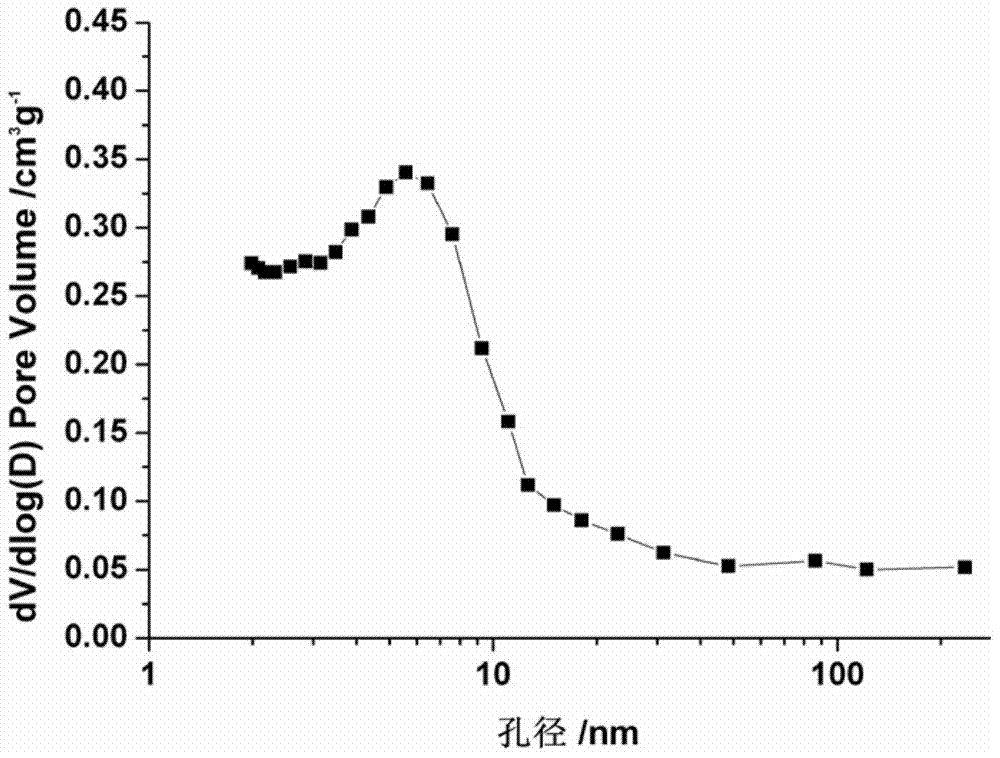

[0027] Get 15g ZSM-5 molecular sieve (Si / Al=37, Na 2 O content 0.25wt%) was added to 200ml containing 0.25mol / L KOH-0.05mol / L NH 4 In the mixed solution of F, magnetically stir at 80°C for 60 minutes, then filter and wash until neutral, dry at 110°C for 12 hours, and then bake in a muffle furnace at 540°C for 3 hours. The obtained molecular sieves were added to 0.8 mol / L ammonium nitrate solution, the solid-to-liquid ratio was 1:20, magnetically stirred at 85°C for 2 hours, then filtered and washed, dried at 120°C for 12h, and then placed in a muffle furnace at 550 ℃ for 6 hours, recorded as sample B.

Embodiment 3

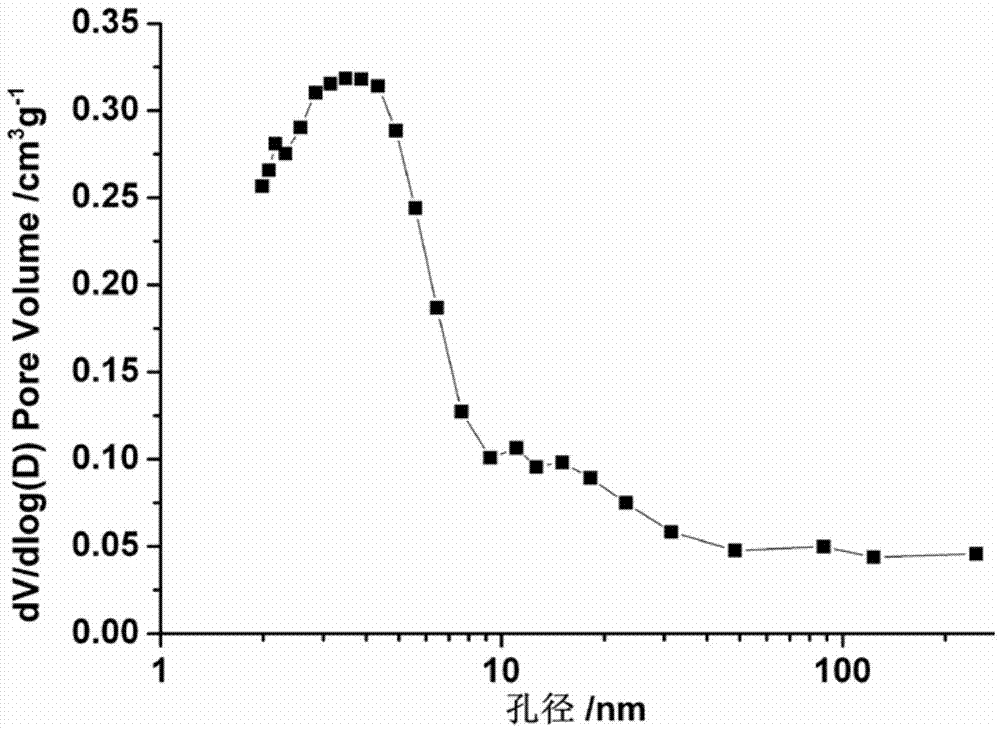

[0029] Get 150g ZSM-5 molecular sieve (Si / Al=60, Na 2 O content 0.09wt%) was added to 1800ml of a mixed solution containing 0.15mol / L NaOH-0.02mol / L KF, stirred magnetically at 55°C for 60 minutes, then filtered and washed until neutral, dried at 120°C for 12 hours and then placed in a muffle The furnace was fired at 530°C for 3 hours. Add the obtained molecular sieves to 0.8 mol / L ammonium nitrate solution, the solid-to-liquid ratio is 1:10, magnetically stir at 80°C for 2 hours, then filter and wash, dry at 120°C for 12 hours, and then place in a muffle furnace Calcined at 530°C for 6 hours, recorded as sample C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com