Method for purifying low-temperature low-turbidity seawater by magnetic-sand-loaded flocculation

A magnet and seawater technology, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, seawater treatment, etc., can solve the problems of slowing down the thermal motion of impurity molecules in water, reducing the probability of particle collision, and unfavorable coagulant hydrolysis, etc. To achieve the effect of reducing drug consumption, volume compression, and saving coagulant drug consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

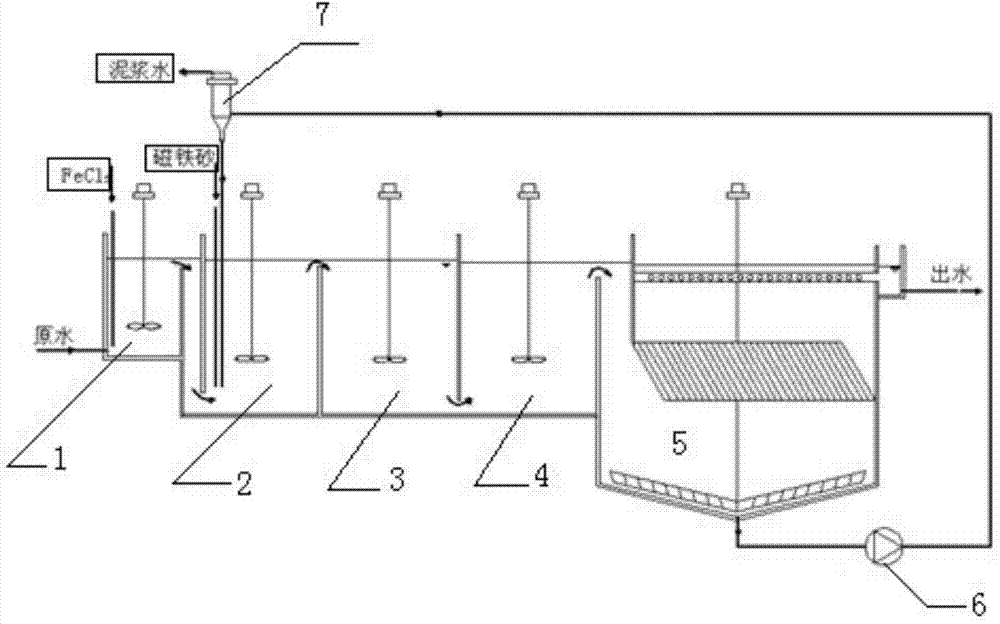

[0020] A method for purifying low-temperature and low-turbidity seawater by flocculation loaded with magnetic sand, comprising the following steps:

[0021] 1. Selection and dosing method of magnetic sand:

[0022] (a) Grinding and screening:

[0023] Set the specific gravity to 4.58g / cm 3 The magnetite is washed, dried, ground, and sieved with a standard sieve to obtain magnetite with a particle size of 75-125 μm. Rinse and infiltrate with water, set aside.

[0024] (b) Dosing method of magnetic sand:

[0025] When adding magnetic sand, wet dosing method must be adopted. During operation, new magnet sand can be added to supplement the shortage of reflow magnet sand.

[0026] 2. Coagulant dosing:

[0027] Add 15-25mg / L of FeCl after the seawater enters the mixing tank 3 Solution, with velocity gradient G=620-700s -1 Stir rapidly to mix for 1 min.

[0028] 3. Magnet sand dosing:

[0029] Contains coagulant FeCl 3 The seawater enters the flocculation tank A, and the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com