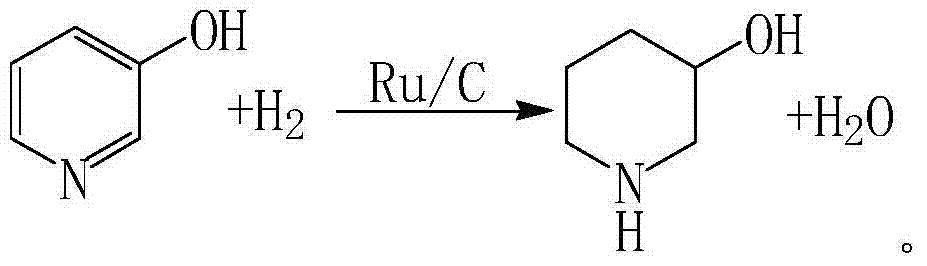

Method for preparing 3-hydroxypiperidine through liquid phase catalytic hydrogenation of 3-hydroxypyridine

A technology of hydroxypyridine liquid and hydroxypiperidine is applied in the field of liquid-phase catalytic hydrogenation of 3-hydroxypyridine to prepare 3-hydroxypiperidine, which can solve the problems of undiscovered 3-hydroxypiperidine research and reports, etc., and achieves cost Inexpensive, high-yield, high-quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The method for preparing 3-hydroxypiperidine by liquid-phase catalytic hydrogenation of 3-hydroxypyridine in this embodiment comprises the following steps:

[0022] Step 1. Add 50g of 3-hydroxypyridine, 1.0g of ruthenium carbon catalyst with 5% ruthenium mass content and 200mL of pure water into the autoclave, first adopt the method of feeding nitrogen to get rid of the air in the autoclave, and then use The method of feeding hydrogen is used to get rid of the nitrogen in the autoclave;

[0023] Step 2. Heat the autoclave after nitrogen removal in step 1, and at the same time, continue to feed hydrogen into the autoclave, and make 3-hydroxypyridine catalyze in liquid phase under the conditions of temperature of 140°C and pressure of 4.0MPa Hydrogenation reduction reaction, after 13 hours of reaction, stop feeding hydrogen, filter and recover the ruthenium carbon catalyst after natural cooling, carry out vacuum distillation on the filtered filtrate at a temperature of 67...

Embodiment 2

[0026] The method for preparing 3-hydroxypiperidine by liquid-phase catalytic hydrogenation of 3-hydroxypyridine in this embodiment comprises the following steps:

[0027] Step 1. Add 100g 3-hydroxypyridine, 2.0g ruthenium carbon catalyst with 5% ruthenium mass content and 200mL pure water into the autoclave, first adopt the method of feeding nitrogen to get rid of the air in the autoclave, and then use The method of feeding hydrogen is used to get rid of the nitrogen in the autoclave;

[0028] Step 2. Heat the autoclave after nitrogen removal in step 1, and at the same time, continue to feed hydrogen into the autoclave, and make 3-hydroxypyridine catalyze in liquid phase under the conditions of temperature of 140°C and pressure of 4.0MPa Hydrogenation reduction reaction, after 14 hours of reaction, stop feeding hydrogen, filter and recover the ruthenium carbon catalyst after natural cooling, carry out vacuum distillation on the filtered filtrate at a temperature of 67°C-69°C ...

Embodiment 3

[0031] The method for preparing 3-hydroxypiperidine by liquid-phase catalytic hydrogenation of 3-hydroxypyridine in this embodiment comprises the following steps:

[0032] Step 1, 150g 3-hydroxypyridine, 4.5g ruthenium mass content is 5% ruthenium charcoal catalyst and 450mL pure water are added in the autoclave, first adopt the method for feeding nitrogen to get rid of the air in the autoclave, then use The method of feeding hydrogen is used to get rid of the nitrogen in the autoclave;

[0033] Step 2. Heat the autoclave after nitrogen removal in step 1, and at the same time, continue to feed hydrogen into the autoclave, and make 3-hydroxypyridine catalyze in liquid phase under the conditions of temperature of 140°C and pressure of 4.0MPa Hydrogenation reduction reaction, after 13 hours of reaction, stop feeding hydrogen, filter and recover the ruthenium carbon catalyst after natural cooling, carry out vacuum distillation on the filtered filtrate at a temperature of 67°C-69°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com