Method for preparing wood-plastic material by coating polyacrylate with wood powder

A technology for polyacrylate and wood-plastic materials is applied in the field of preparation of wood-plastic materials, which can solve the problems of difficult cost reduction and complicated process, and achieve the effects of low cost, simple preparation method and beautiful wooden appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

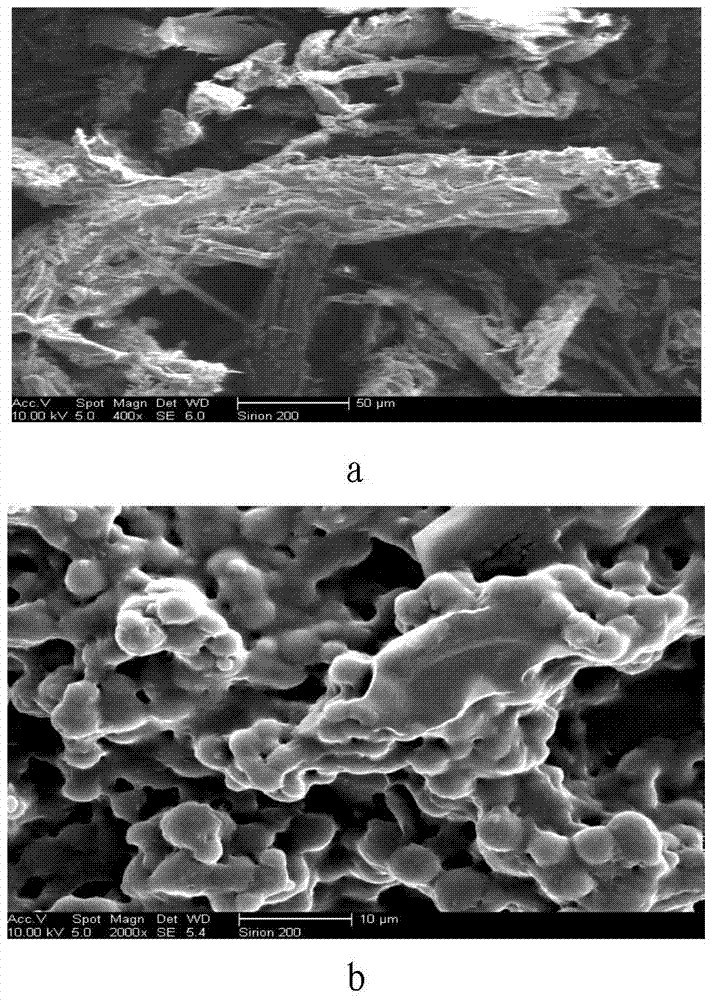

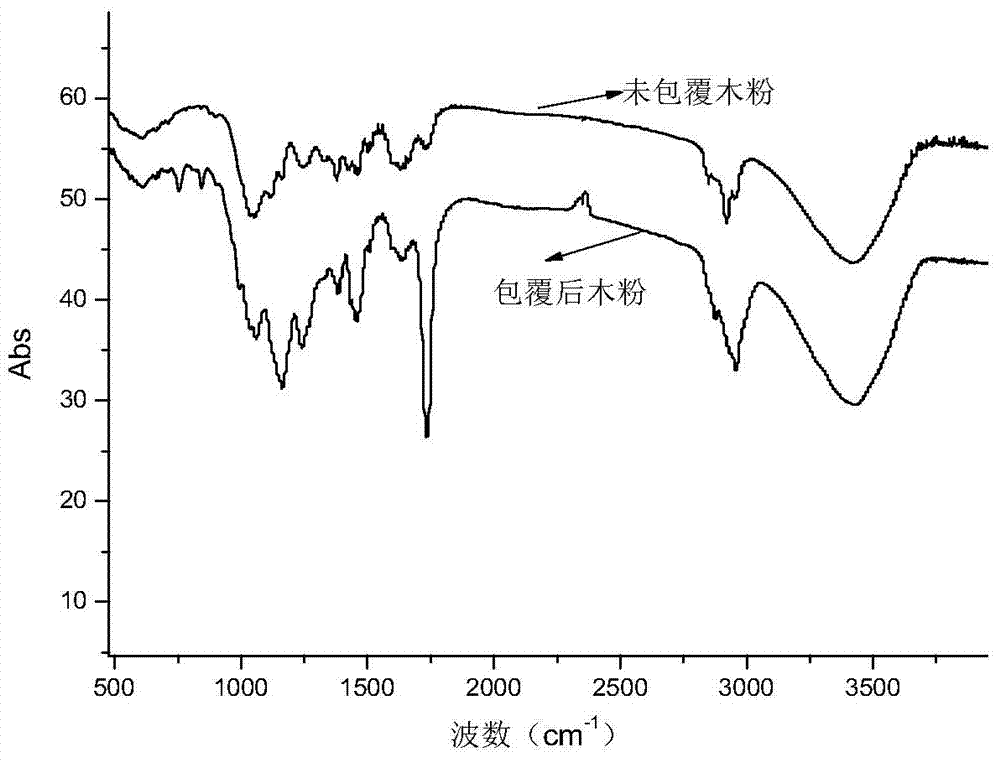

Image

Examples

Embodiment 1

[0025] The concrete steps of preparation are:

[0026] Step 1: First, mix butyl acrylate, acrylic acid and sodium dodecylsulfonate in a weight ratio of 13:1.5:3 to obtain a mixed solution. Then the mixed solution and 6.5wt% azobisisobutyronitrile methyl methacrylate solution were added dropwise to the 0.04wt% 100-mesh wood flour aqueous solution at 75°C under stirring within 26 minutes at the same time, and then the insulation polymerization was continued. Reacted for 3h to obtain a reaction solution.

[0027] In step 2, the reaction solution is first subjected to solid-liquid separation, washing and drying in sequence; wherein, the solid-liquid separation process is filtration separation, the washing process is to use ethanol to clean the separated solid matter, and the drying process is to wash the cleaned The solid matter is dried at 60° C. to obtain a modified wood powder coated with polyacrylate. After the modified wood flour was dried at 100°C for 5 hours, the modified...

Embodiment 2

[0029] The concrete steps of preparation are:

[0030] In step 1, butyl acrylate, acrylic acid and sodium dodecylsulfonate are mixed in a weight ratio of 13:1.8:2.8 to obtain a mixed solution. Then the mixed solution and 6.8wt% azobisisobutyronitrile methyl methacrylate solution were added dropwise to the 0.05wt% 95-mesh wood flour aqueous solution at 78°C under stirring within 27 minutes at the same time, and then the insulation polymerization was continued. After 3.5 hours of reaction, the reaction solution was obtained.

[0031] In step 2, the reaction solution is first subjected to solid-liquid separation, washing and drying in sequence; wherein, the solid-liquid separation process is filtration separation, the washing process is to use ethanol to clean the separated solid matter, and the drying process is to wash the cleaned The solid matter is dried at 65° C. to obtain a modified wood powder coated with polyacrylate. After the modified wood flour was dried at 103°C for...

Embodiment 3

[0033] The concrete steps of preparation are:

[0034] Step 1: First, mix butyl acrylate, acrylic acid and sodium dodecylsulfonate according to the weight ratio of 13:2:2.5 to obtain a mixed solution. Then the mixed solution and 7wt% azobisisobutyronitrile methyl methacrylate solution were added dropwise to the 0.06wt% 90-mesh wood flour aqueous solution at 80°C under stirring within 28 minutes, and then the insulation polymerization was continued. 4h, the reaction solution was obtained.

[0035] In step 2, the reaction solution is first subjected to solid-liquid separation, washing and drying in sequence; wherein, the solid-liquid separation process is filtration separation, the washing process is to use ethanol to clean the separated solid matter, and the drying process is to wash the cleaned The solid matter is dried at 70° C. to obtain a modified wood powder coated with polyacrylate. After the modified wood flour was dried at 105°C for 5 hours, the modified wood flour an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com