Machine-washable cashmere sweater

A technology for cashmere sweaters and cashmere, which is applied in biochemical fiber treatment, dyeing, textiles and papermaking, etc. It can solve the problems of easy deformation and cashmere sweaters can only be washed by hand, and achieve the effects of improved strength, good hand feeling and low processing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Cashmere selection and cashmere opening: select 16.0um cashmere fibers with a length of 35-38mm, use the cashmere turbine to open the selected cashmere, and open the cashmere through multiple light beating turbines.

[0044] (2) Enzyme treatment and washing:

[0045] Both papain and bromelain are food grade with an activity of 500,000 u / g.

[0046] The first pass: 1% papain + 1% sodium bisulfite aqueous solution, the water temperature is kept at 55°C; the pH is controlled at 7, and the treatment time is 20 minutes;

[0047] The second pass: 1.5% bromelain, the water temperature is kept at 50°C; the pH is controlled at 7, and the treatment time is 10 minutes;

[0048]After enzyme treatment, rinse with clean water and keep the temperature at 55°C;

[0049] Enzyme-treated cashmere removes all kinds of dirt and is chemically altered;

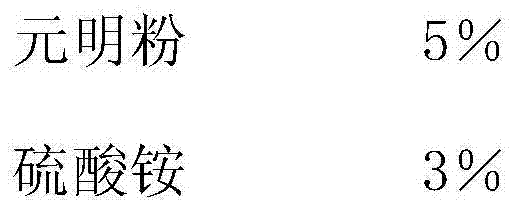

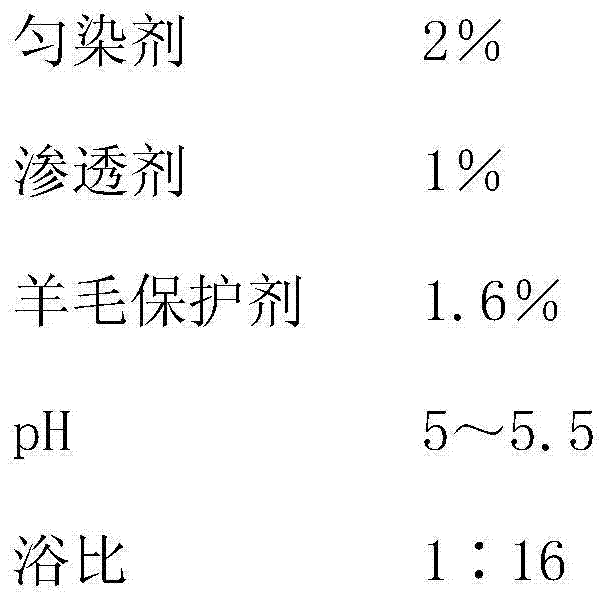

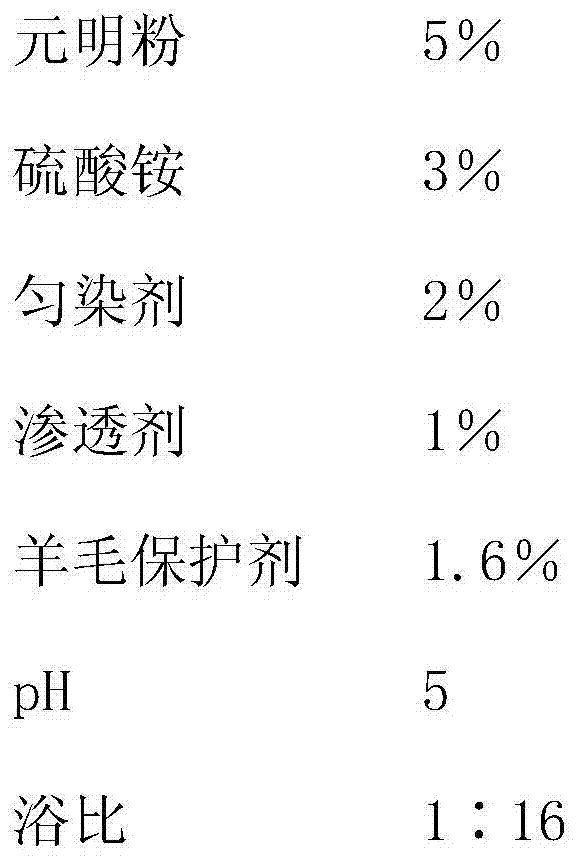

[0050] (3) low temperature dyeing:

[0051] The wool is dyed with reactive dyes, the dyeing temperature is controlled at 70°C, and t...

Embodiment 2

[0066] (1) Cashmere selection and cashmere opening: select 16.0um cashmere fibers with a length of 35-38mm, use the cashmere turbine to open the selected cashmere, and open the cashmere through multiple light beating turbines.

[0067] (2) Enzyme treatment and washing:

[0068] Both papain and bromelain are food grade with an activity of 500,000 u / g.

[0069] The first pass: 1% papain + 1% sodium bisulfite aqueous solution, the water temperature is kept at 55°C; the pH is controlled at 7, and the treatment time is 20 minutes;

[0070] The second pass: 1.5% bromelain, the water temperature is kept at 50°C; the pH is controlled at 7, and the treatment time is 10 minutes;

[0071] After enzyme treatment, rinse with clean water and keep the temperature at 55°C;

[0072] Enzyme-treated cashmere removes all kinds of dirt and is chemically altered;

[0073] (3) low temperature dyeing:

[0074] The wool is dyed with reactive dyes, the dyeing temperature is controlled at 80°C, and ...

Embodiment 3

[0089] (1) Cashmere selection and cashmere opening: select 16.0um cashmere fibers with a length of 35-38mm, use the cashmere turbine to open the selected cashmere, and open the cashmere through multiple light beating turbines.

[0090] (2) Enzyme treatment and washing:

[0091] Both papain and bromelain are food grade with an activity of 500,000 u / g.

[0092] The first pass: 1% papain + 1% sodium bisulfite aqueous solution, the water temperature is kept at 55°C; the pH is controlled at 7, and the treatment time is 20 minutes;

[0093] The second pass: 1.5% bromelain, the water temperature is kept at 50°C; the pH is controlled at 7, and the treatment time is 10 minutes;

[0094] After enzyme treatment, rinse with clean water and keep the temperature at 55°C;

[0095] Enzyme-treated cashmere removes all kinds of dirt and is chemically altered;

[0096] (3) low temperature dyeing:

[0097] The wool is dyed with reactive dyes, the dyeing temperature is controlled at 75°C, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com