Device for testing hydrothermal variation features of hydrous porous medium in freeze thawing process

A porous medium and thermal change technology, applied in measuring devices, material thermal analysis, instruments, etc., can solve problems such as inconsistencies in freezing and melting curves, and achieve the effects of fast overall temperature rise and fall, simplified data analysis process, and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

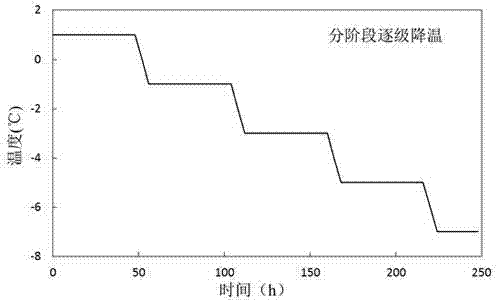

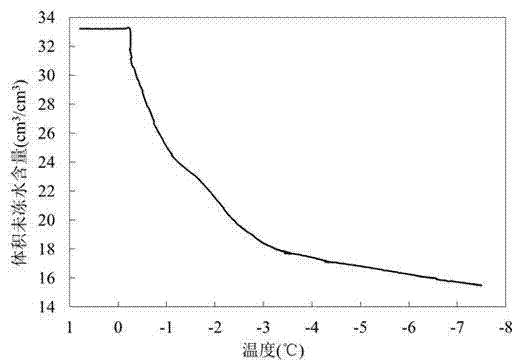

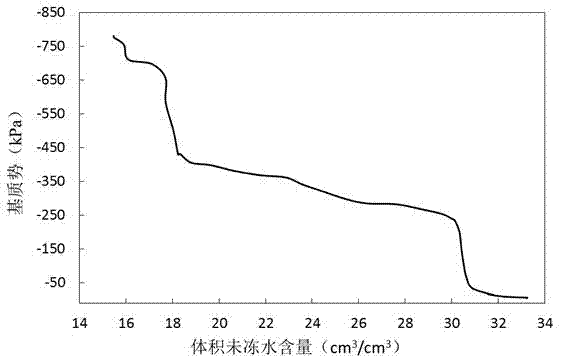

[0018] Below in conjunction with accompanying drawing, the present invention is described further:

[0019] Such as figure 1 As shown, a device for testing the characteristics of hydrothermal changes in the freezing and thawing process of aqueous porous media is composed of a model outer box 1, an outer box top cover 2, a refrigeration coil 3, a cold bath liquid interface 4, a sensor lead hole 5, Outer box base 6, model inner box 7, inner box base 8, inner box top cover 9, sealing ring 10, lead pipe 11, fastening bolt 12, catheter 13, 1# cold bath 14, 2# cold bath 15 , cold bath liquid 16, filling liquid 17, temperature sensor 18, moisture sensor 19, water potential sensor 20, data acquisition instrument 21 and electronic computer 22 composition. Model inner box 7 and model outer box 1 can be cuboid or cylinder. The length of each side of the cuboid and the diameter and height of the cylinder are not less than 0.60 m, the length of each side and the diameter and height of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com