A liquid constant pressure specific heat capacity measuring device

A technology of constant pressure specific heat capacity and measuring device, applied in the direction of material thermal development, etc., can solve the problems of complicated and huge system, complicated pressure regulation process, inconvenient use, etc., and achieve the effect of strengthening heat transfer performance, simple structure and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

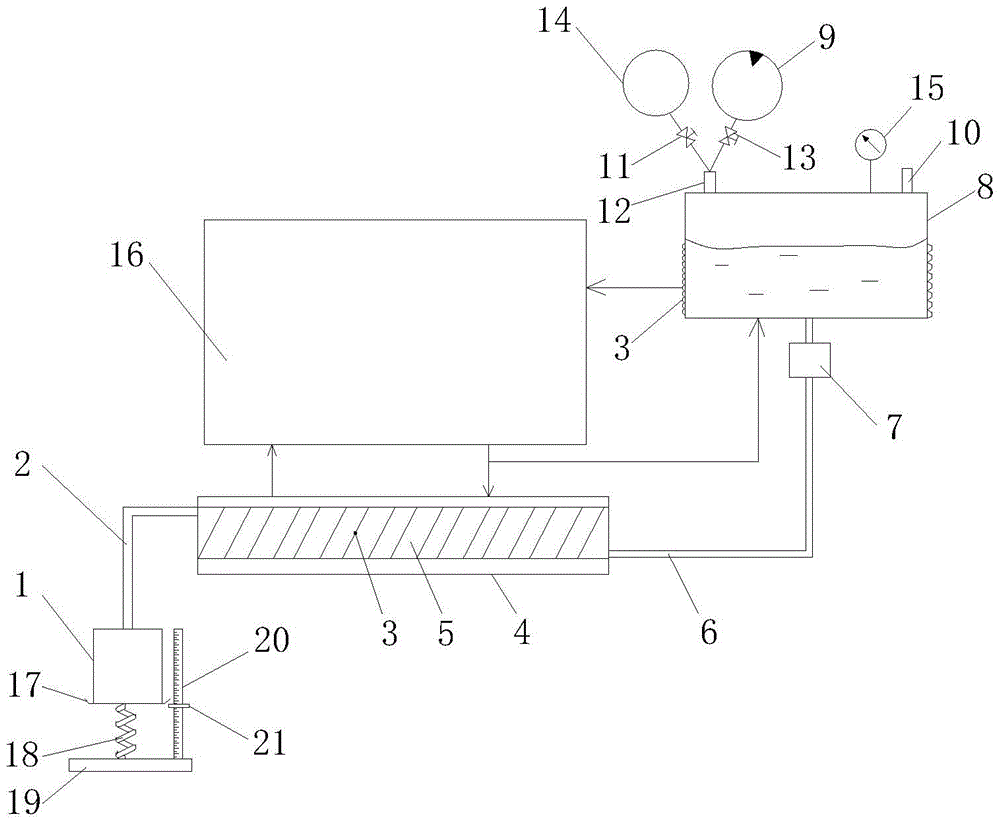

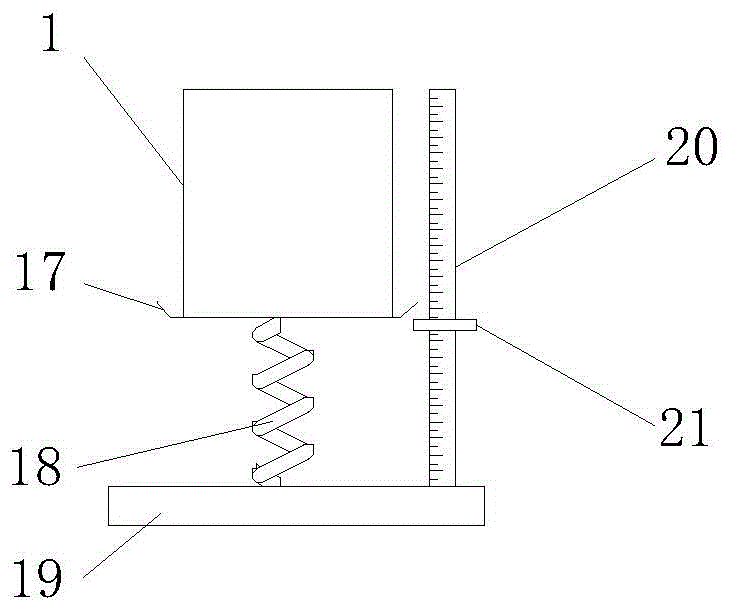

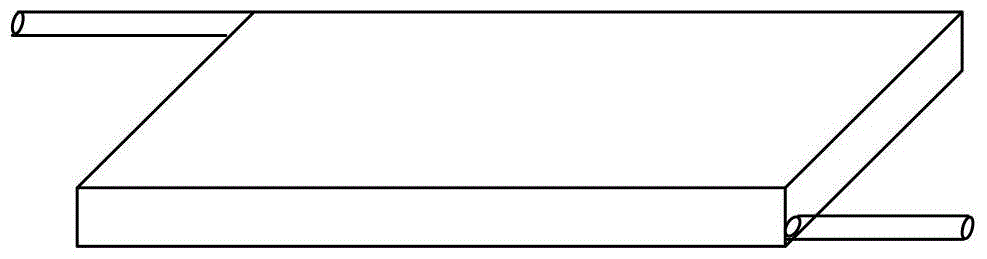

[0030] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0031] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 Shown, the present invention comprises temperature control system 16, flow meter, collection bottle 1, calorimetric tube 5 and liquid pool 8, and flow meter comprises base 19, and spring 18 and scale 20 are vertically arranged on base 19, and spring 18 The lower end is fixed on the base 19, the upper end of the spring 18 is provided with a tray 17, the collection bottle 1 is placed in the tray 17, the calorimetric tube 5 is a rectangular parallelepiped structure, and the surfaces of the calorimetric tube 5 and the liquid pool 8 are arranged with thermoelectric temperature control sheets 3 , the power output end of the temperature control system 16 is connected to the thermoelectric temperature control sheet 3, and the temperature data acquisition end of the temperature control system 16 is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com