Composite focus space-time synchronized drilling system and method

A drilling method and focus technology, applied in the field of compound focus space-time synchronous drilling system, can solve the problems of increasing processing procedures, reducing processing efficiency, and high product rejection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

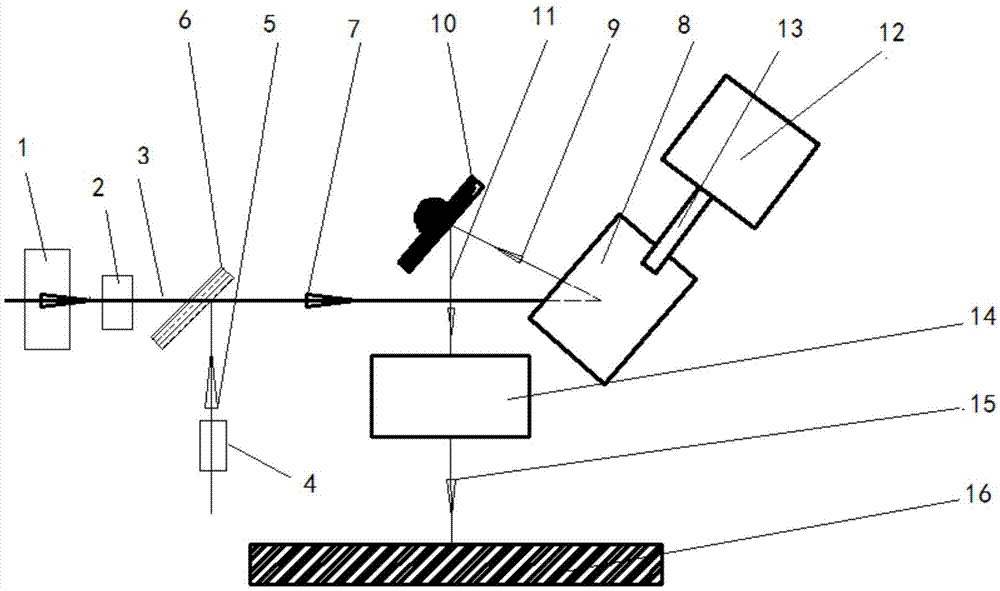

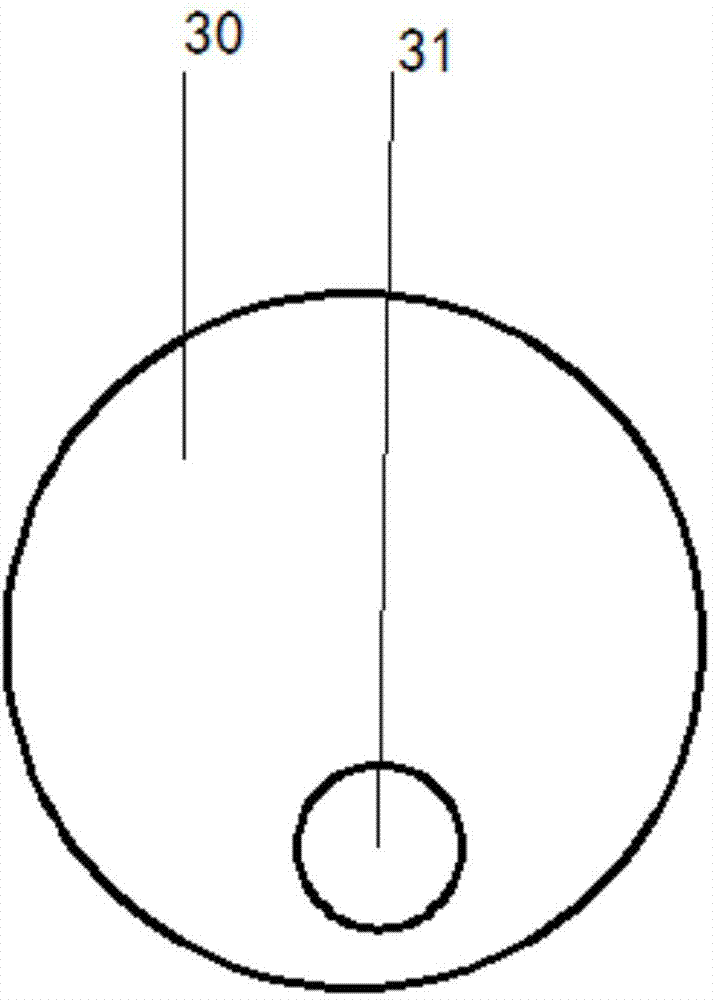

[0040] Embodiment 1. A multi-focus space-time synchronous drilling system suitable for blind holes of printed circuit boards. Combine below figure 1 with image 3 as well as Figure 4 The system provided in this embodiment will be described in detail.

[0041] figure 1 A schematic diagram of a system for drilling blind holes in printed circuit boards using the method provided in this embodiment, as shown in figure 1 As shown, the system provided in this embodiment includes a scanning motion drilling laser 1 , a scanning motion drilling laser modulator 2 , a heating and cleaning laser 4 , a laser beam combiner 6 , a laser focusing and focus switching module, and a workpiece 16 to be processed.

[0042] The scanning motion drilling laser 1 generates the first scanning motion drilling laser beam, and performs spatial motion modulation on it through the scanning motion drilling laser modulator 2, and the modulated first scanning motion drilling laser beam 3 incident laser comb...

Embodiment 2

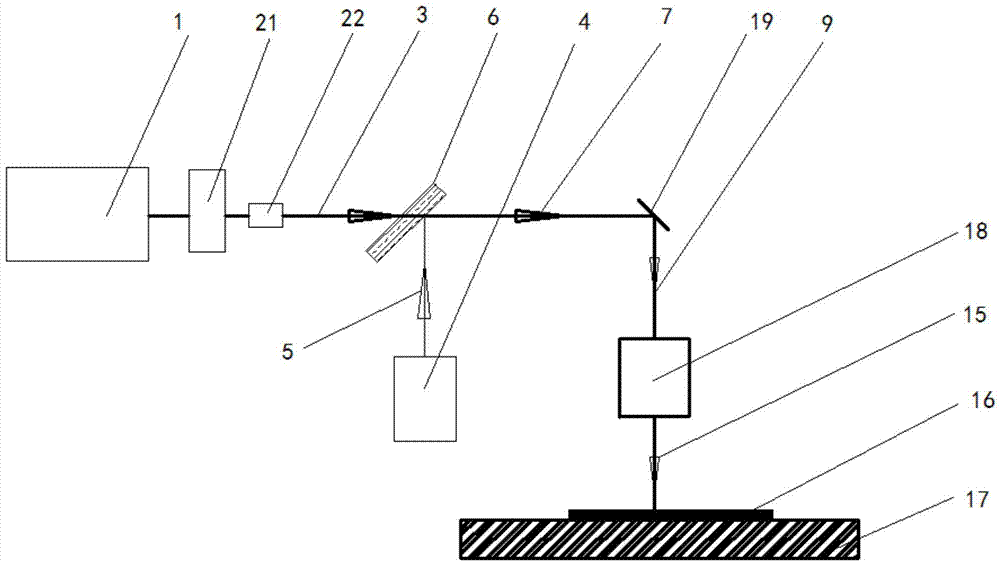

[0057] Embodiment 2. A composite focus space-time synchronous drilling system suitable for silicon wafer group holes. Combine below figure 2 , image 3 with Figure 4 The system provided in this embodiment will be described.

[0058] The composite focus space-time synchronous drilling system suitable for silicon wafer group holes has similarities with the composite space-time synchronous drilling system suitable for printed circuit boards in Embodiment 1, which can be found in figure 2 , The system provided in this embodiment includes a scanning motion drilling laser 1, a scanning motion drilling laser modulator 2, a heating and cleaning laser 4, a laser beam combiner 6, and a laser focusing and focus switching module.

[0059] Wherein, the scanning motion drilling laser modulator 2 is an acousto-optic deflector 21 and 22 placed orthogonally, it may also be an electro-optic deflector, it may also be a mirror driven by a piezoelectric ceramic or a galvanometer, or it may b...

Embodiment 3

[0068] Embodiment 3, a flow chart of a compound focus space-time synchronous drilling method. Combine below Figure 5 The method provided in this embodiment will be described in detail.

[0069] see Figure 5, the main working process of the method provided in this embodiment is: combining the first heating and cleaning laser beam and the first scanning motion drilling laser beam modulated by spatial motion to output the second heating and cleaning laser beam and the first Two scanning motion drilling laser beams form a laser beam group, so that the axis of symmetry of the spatial trajectory of the optical axis of the second scanning motion drilling laser beam is coaxial or paraxial with the optical axis of the second heating and cleaning laser beam, and the Paraxial means that the spatial angle between the axis of symmetry of the optical axis of the second scanning motion drilling laser beam and the optical axis of the second heating and cleaning laser beam is less than 10°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com