A Grinding Method for Controlling Grinding Parameters

A grinding parameter and grinding technology, which is applied in the direction of grinding machine tool parts, grinding/polishing equipment, workpiece feed movement control, etc., can solve the problem that the grinding temperature cannot be detected and controlled, and the grinding parameters cannot be controlled. The method and the poor consistency of processing quality can achieve the effect of improving the consistency of grinding processing quality, high accuracy and ensuring grinding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

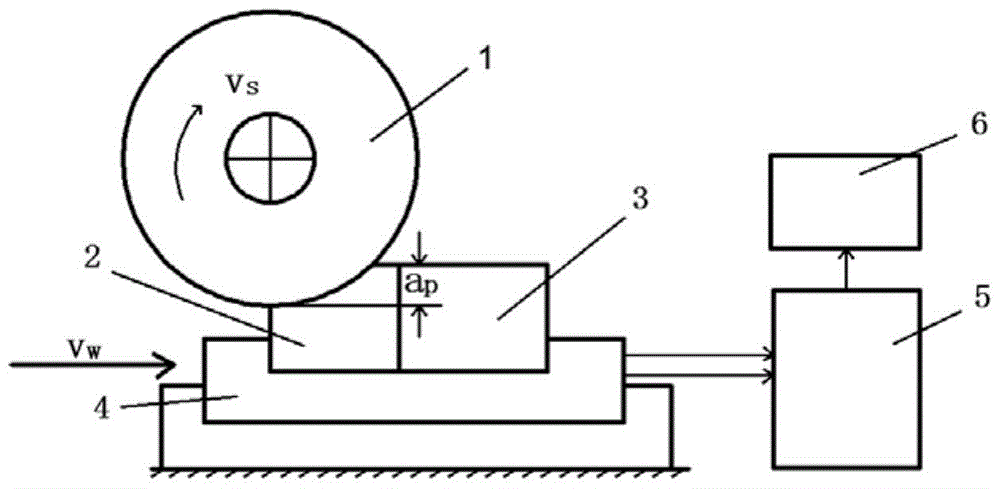

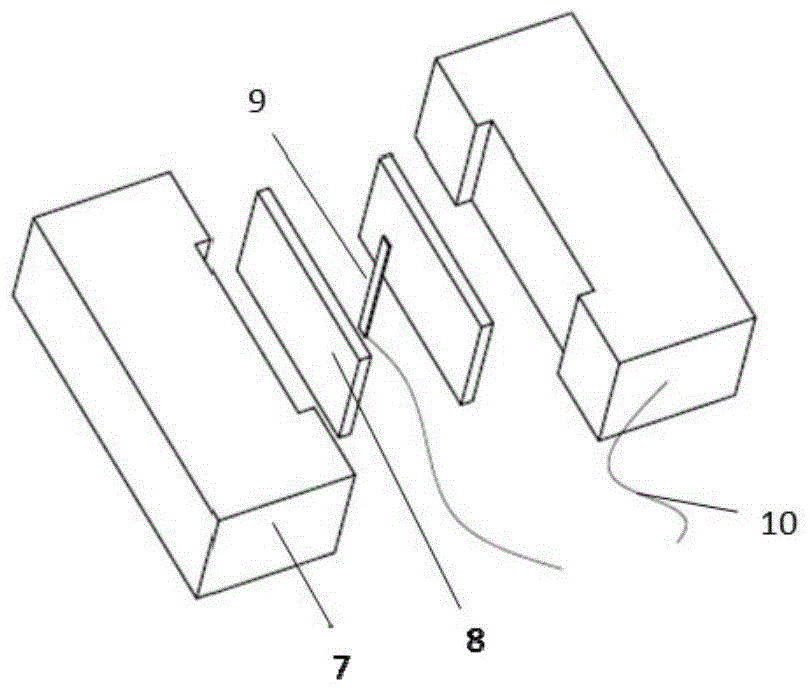

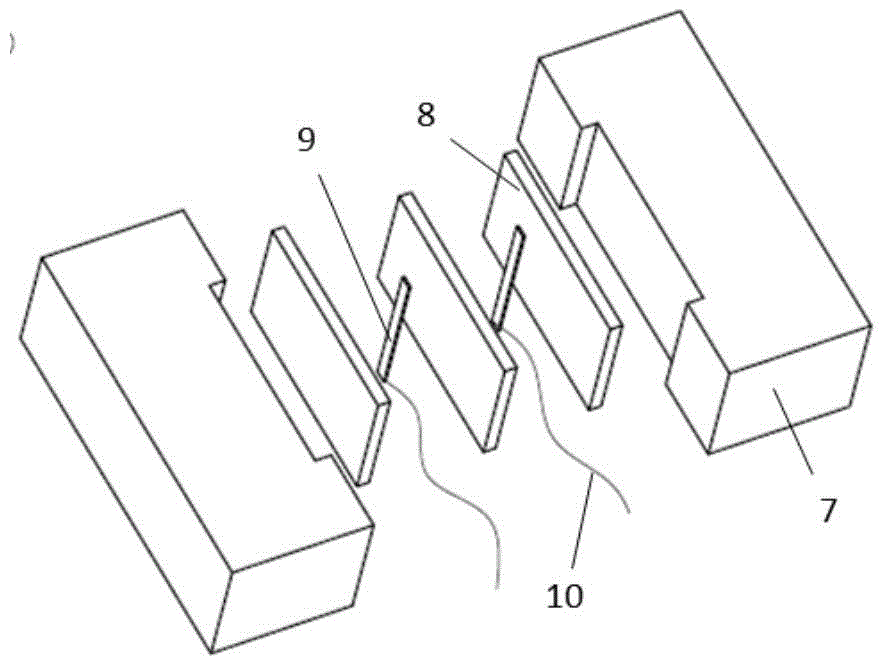

[0034] The specific embodiment of the present invention will be described in detail below in conjunction with the technical scheme and accompanying drawings. The processed material is an example of the two-phase titanium alloy TC17 material used in aero-engines. Its matrix structure is a basket structure with high strength and low thermal conductivity. High chemical activity. Using 80 # Microcrystalline corundum grinding wheel, for plunge-cut grinding test, figure 1 It is a schematic diagram of the entire experimental device. In order to ensure the integrity of the workpiece, a temperature measuring sample 2 of the same material as the workpiece 3 to be processed is selected, and placed in the insulating fixture 4 close to the workpiece 3 to be processed; the insulating fixture 4 Place it on the grinder work platform. When the workpiece 3 to be processed is a non-metallic material, such as image 3 As shown in the wire type artificial thermocouple, since the workpiece 3 to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com