Polycarbonate diol containing carbonate compound

A polycarbonate diol and compound technology, applied in polycarbonate coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as strong interaction and damage to the surface smoothness of the coating film, and achieve smooth coating. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

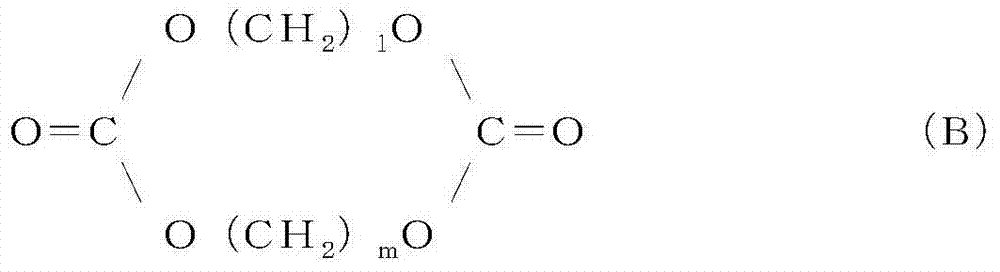

[0190] Put 640g (7.3mol) ethylene carbonate, 400g (3.9mol) 1,5-pentanediol, 410g (3.5mol) into a 2L glass flask equipped with a rectification tower filled with regular packing and a stirring device ) 1,6-Hexanediol. 0.35 g of titanium tetraisopropoxide as a catalyst was further added to the flask, and the mixture in the flask was stirred and heated under normal pressure to start the reaction. The reaction start temperature was set to 140°C, and the reaction was performed at this temperature for 15 hours. Then, the reaction temperature was slowly raised to 160°C over 15 hours, and the reaction was carried out while distilling off the produced mixture of ethylene glycol and ethylene carbonate. Then, the pressure in the flask was reduced to 10 kPa, and the reaction was carried out at 164° C. for a further 15 hours while distilling off the mixture of the diol and ethylene carbonate. Then, 0.39 g of 2-ethylhexyl acid phosphate was added as a phosphorus compound to the flask, and t...

Embodiment 2

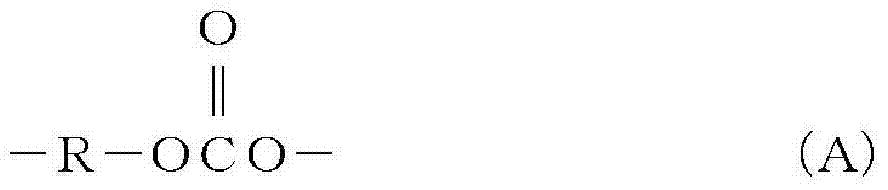

[0192] Let the addition amount of 1,3,9,11-tetraoxacycloheptadecanyl-2,10-dione (in formula (B), the carbonate compound in the case of l=5 and m=6) be Except 0.5 g, the same method as in Example 1 was used to obtain a polycarbonate diol composition. Table 1 shows the result of analyzing the obtained polycarbonate diol composition. This polycarbonate diol composition is abbreviated as PC-2. The obtained polycarbonate diol has a repeating unit represented by the formula (A) and a terminal hydroxyl group, and the R and the ratio of each repeating unit are shown in Table 1.

Embodiment 3

[0194] Let the addition amount of 1,3,9,11-tetraoxacycloheptadecyl-2,10-dione (in formula (B), the carbonate compound in the case of l=5 and m=6) be Except 11 g, the same method as in Example 1 was used to obtain a polycarbonate diol composition. Table 1 shows the result of analyzing the obtained polycarbonate diol composition. This polycarbonate diol composition is abbreviated as PC-3. The obtained polycarbonate diol has a repeating unit represented by the formula (A) and a terminal hydroxyl group, and the R and the ratio of each repeating unit are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com