Hydrogen removal method and system for aluminum melt

A technology of aluminum melt and hydrogen system, which is applied in the field of hydrogen removal method and system of aluminum melt, can solve problems such as hindering hydrogen diffusion and environmental pollution, and achieve the effects of improving pumping efficiency, reducing pollution, and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

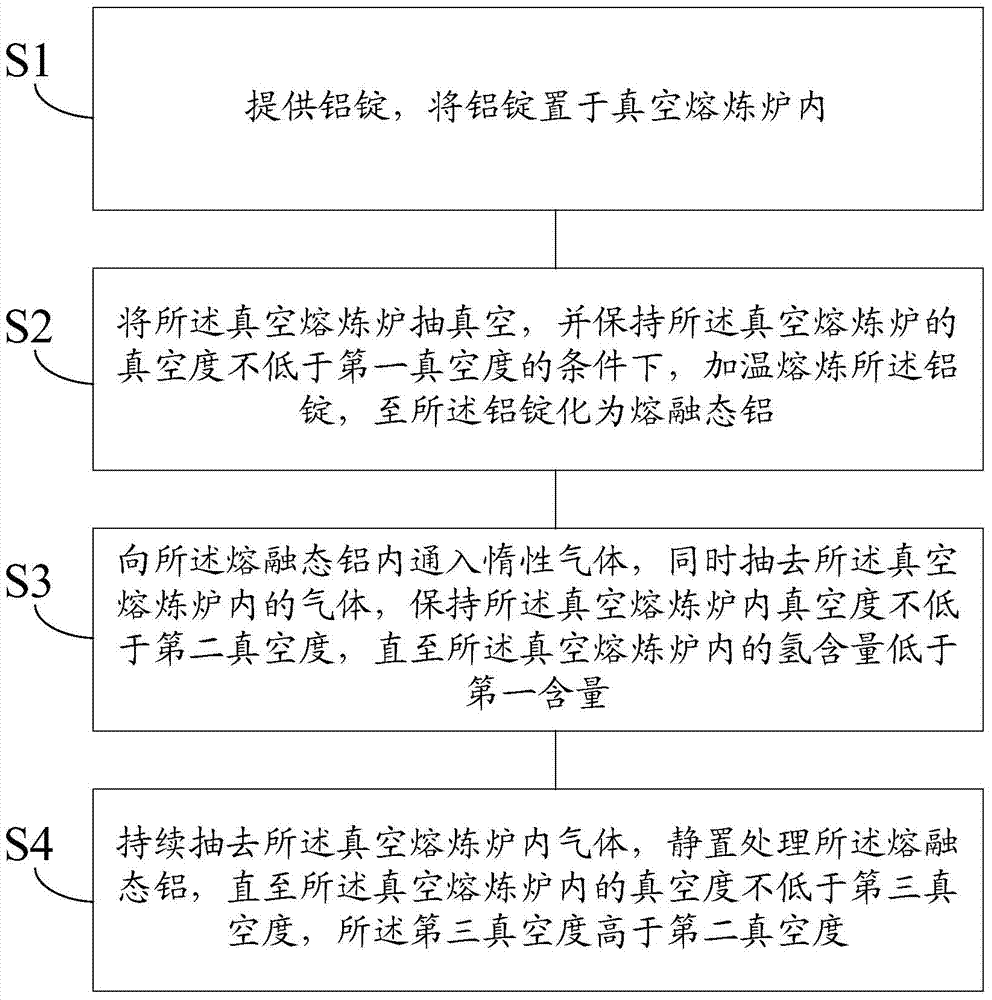

[0041] As mentioned in the background art, aluminum alloy materials in the semiconductor industry have high requirements for purity and density. However, in the existing hydrogen removal schemes for aluminum melts, including vacuum hydrogen removal and floating hydrogen removal, the hydrogen removal effect is poor, so that more hydrogen remains in the obtained pure aluminum and alloys, which affects the obtained pure aluminum. and alloy quality.

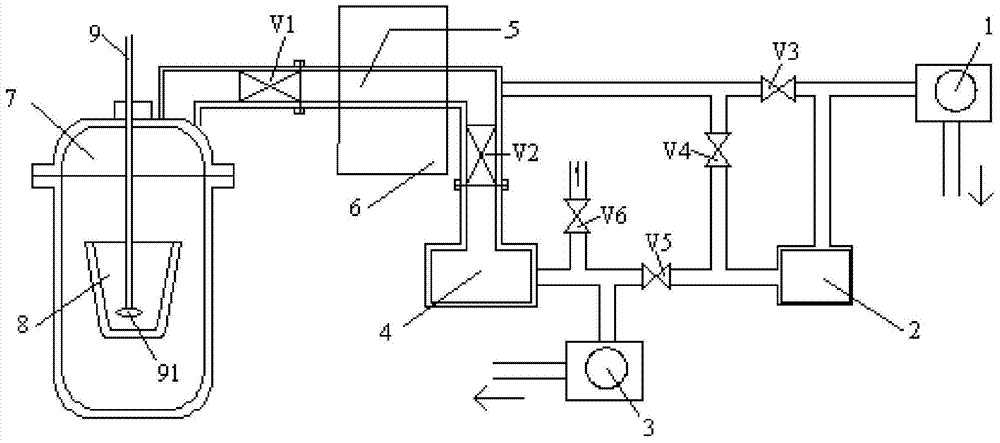

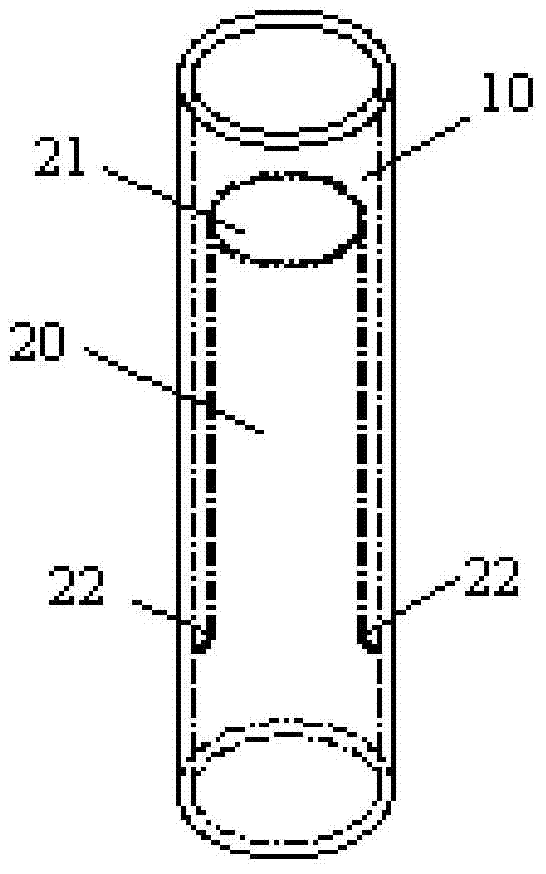

[0042] In view of the above defects, the present invention provides a method for removing hydrogen from molten aluminum and a system for removing hydrogen from molten aluminum. In the method for removing hydrogen from the aluminum melt, in the vacuum smelting furnace, after the aluminum ingot is heated into molten aluminum, the inert gas is continuously introduced into the molten aluminum, so that the hydrogen gas in the molten aluminum is separated out, and at the same time, the hydrogen gas in the molten aluminum is continuously pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com