TiCN-based steel-bonded cemented carbide, and preparation method and application thereof

A technology of steel-bonded cemented carbide and hard phase, applied in the field of powder metallurgy, can solve the problem that the interface between hard phase TiCN particles and the matrix is not well combined, the strengthening effect of TiCN particles cannot be exerted well, and the TiCN hard phase Problems such as poor compatibility with the steel matrix, to achieve the effects of reduced barriers to migration, good deoxidation, excellent high temperature red hardness and oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

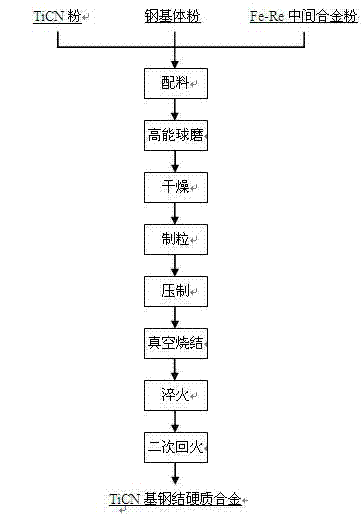

[0030] The preparation method of the above-mentioned TiCN-based steel-bonded hard alloy adopts powder metallurgy, comprising the following steps:

[0031] Step 1: Master alloy preparation, with Fe, Ce, La as raw materials, based on the total mass of Fe—(20~30%) Ce—(8~20%) La master alloy, 20~30% Ce by weight percentage , 8~20% La, the balance is Fe to carry out batching, adopts conventional smelting method to prepare Fe—(20~30%) Ce—(8~20%)La master alloy melt, the Fe—(20 ~30%)Ce—(8~20%)La master alloy melt is made into Fe—(20~30%)Ce—(8~20%)La master alloy powder by conventional water atomization method;

[0032] Step 2: batching, the steel matrix raw material powder, the Fe—(20~30%) Ce—(8~20%) La master alloy powder and TiCN powder prepared in step 1 are batched according to weight percentage;

[0033] Step 3: ball milling and mixing the raw materials obtained in the step 2;

[0034] Step 4: molding the mixture obtained in step 3;

[0035] Step 5: Sintering the compact obta...

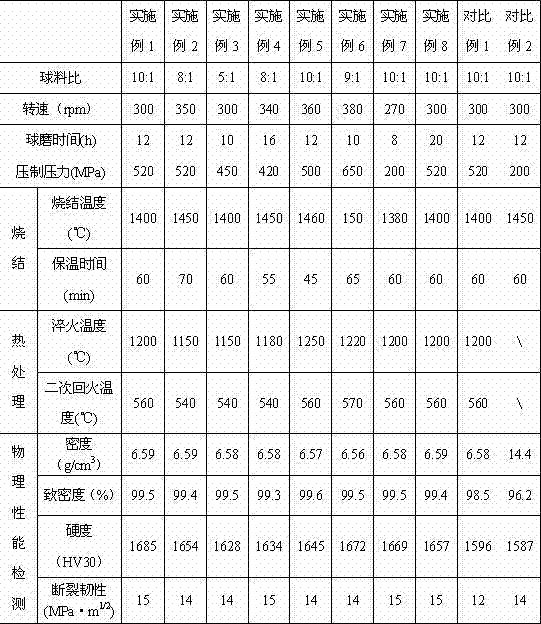

Embodiment 1

[0042] A TiCN-based steel-bonded hard alloy, the TiCN-based steel-bonded hard alloy uses TiCN as a hard phase, a steel matrix as a binder phase, Fe-28%Ce-10%La intermediate alloy as an additive, and TiCN Based on the total weight of the steel-bonded hard alloy, the percentage by weight of the TiCN is 35%, the percentage by weight of the steel matrix is 64.3%, and the weight of the Fe-28%Ce-10%La master alloy The percentage is 0.7%, and the raw material composition of the steel matrix includes W powder, Mo powder, V powder, Cr powder, Ni powder, Cu powder, carbon black powder, carbonyl iron powder, and reduced iron powder. The mass percentages of the components of the steel matrix in the total mass of the TiCN-based steel-bonded hard alloy are as follows: 4.2% W powder, 3.5% Mo powder, 1.4% V powder, 2.5% Cr powder, 0.5% Ni powder, 0.4% Cu powder, 0.6% carbon black powder, 14% carbonyl iron powder, 37.4% reduced iron powder.

[0043] The preparation method of the above-menti...

Embodiment 2

[0053]A TiCN-based steel-bonded hard alloy, the TiCN-based steel-bonded hard alloy uses TiCN as a hard phase, a steel matrix as a binder phase, Fe-20%Ce-8%La intermediate alloy as an additive, and TiCN Based on the total weight of the steel-bonded hard alloy, the percentage by weight of TiCN is 30%, the percentage by weight of the steel matrix is 69.5%, the percentage by weight of the Fe-20%Ce-8%La intermediate alloy is 0.5%, and the weight percentage of the steel matrix is 0.5%. The mass percentages of the ingredients in the total mass of TiCN-based steel-bonded cemented carbide are as follows: 3.2% W powder, 2.8% Mo powder, 1% V powder, 1.6% Cr powder, 0.3% Ni powder, 0.3% Cu powder, 0.8% carbon Black powder, 12% carbonyl iron powder, 37.4% reduced iron powder.

[0054] The preparation method of the above-mentioned TiCN-based steel-bonded hard alloy comprises the following steps:

[0055] Step 1: Master alloy preparation, using Fe, Ce, La as raw materials, based on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com