Engine indicating torque estimating method and engine indicating torque circulating circuit

A technology for indicating torque, engine, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve problems such as transient errors, difficult cylinder sensor installation control or diagnostic tasks, complex models, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

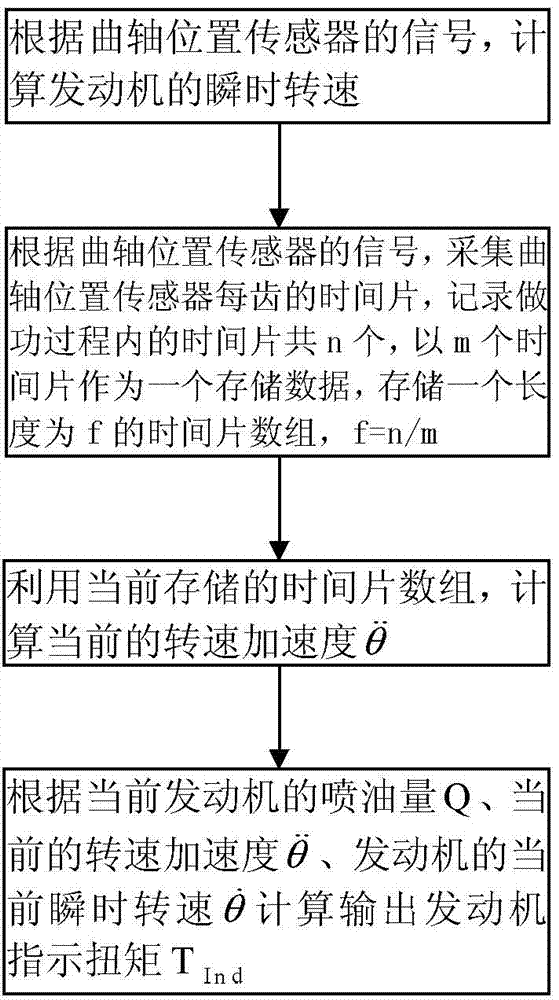

[0042] Engine indicated torque estimation methods such as figure 1 shown, including the following steps:

[0043] 1. Calculate the instantaneous speed of the engine according to the signal of the crankshaft position sensor;

[0044] Whether it is a two-stroke engine or a four-stroke engine, it must go through four working processes of air intake (scavenging), compression, combustion expansion (doing work), and exhaust to complete a working cycle. The difference is that in a four-stroke engine, every two revolutions of the crankshaft (720 degrees), the piston reciprocates twice, and the engine completes a working cycle, that is, every four strokes complete a working cycle. In a two-stroke engine, every time the crankshaft rotates once (360 degrees), the piston reciprocates once, and the engine completes a working cycle, that is, every two strokes complete a working cycle. Every time a two-stroke engine and a four-stroke engine complete a working cycle, the intake and exhaust ...

Embodiment 2

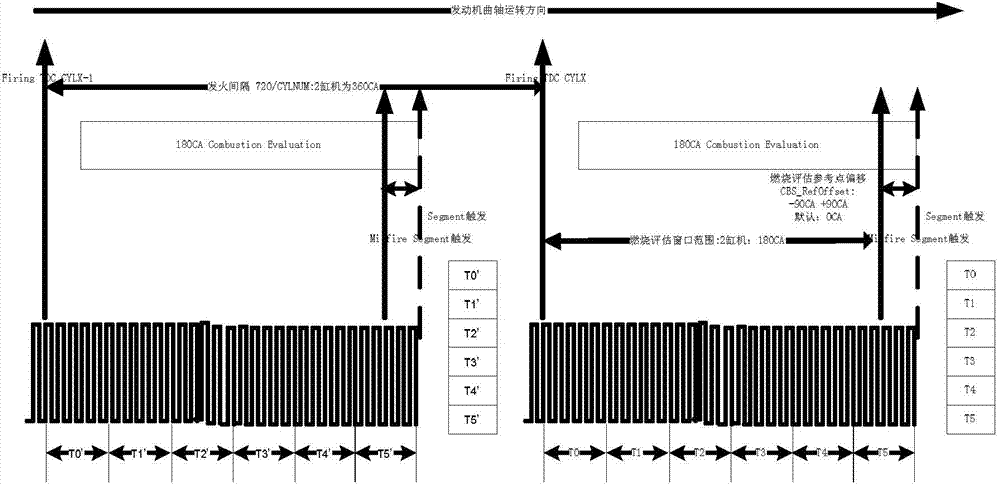

[0061] The collection and recording of the time slice needs to select the work process of the engine, and the calculation of the indicated torque needs to be completed in the current work process and before the next work process comes. Based on the engine indicated torque estimation method of embodiment 1, in step 2, the crankshaft position sensor adopts a crankshaft position signal disc with 58 teeth plus 2 missing teeth to collect the crankshaft position signal of the four-stroke engine, and there are 30 time slices in the work process. Every time slice of 5 teeth is used as a storage data T, and a time slice array with a length of 6 is stored. The specific collection and recording time is as follows figure 2 shown. In step 3, use the currently stored time slice array to calculate the current speed acceleration The specific algorithm is as follows:

[0062] θ . . = ( ...

Embodiment 3

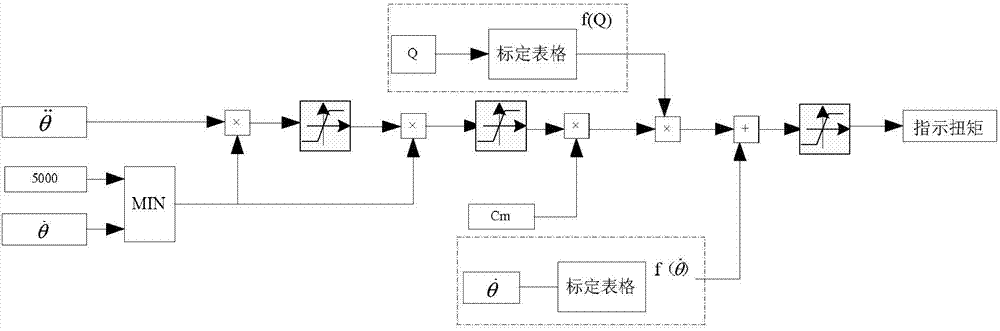

[0064] An indicated engine torque calculation circuit for realizing the engine indicated torque estimation method of Embodiment 1, such as image 3 As shown, it includes the speed acceleration calculation module, the small module, the load factor calculation module, the speed factor calculation module, the first multiplier, the second multiplier, the third multiplier, the fourth multiplier, the adder, the first upper and lower limits A limiting unit, a second upper and lower limit limiting unit, and a third upper and lower limit limiting unit;

[0065] The small module is used to output the smaller value of the two inputs;

[0066] The first upper and lower limit limiting unit, the second upper and lower limit limiting unit, and the third upper and lower limit limiting unit output a lower limit value when the input is less than the lower limit, output an upper limit value when the input is greater than the upper limit, and output an input value when the input is between the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com