Rotary control solid attitude and orbit control engine

A technology of orbit control engine and rotation control, which is applied in the direction of machines/engines, rocket engine devices, mechanical equipment, etc. It can solve the problems of poor control accuracy, high requirements of basic industry, ablation, etc., and achieve high reliability, simple structure, Facilitate the control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

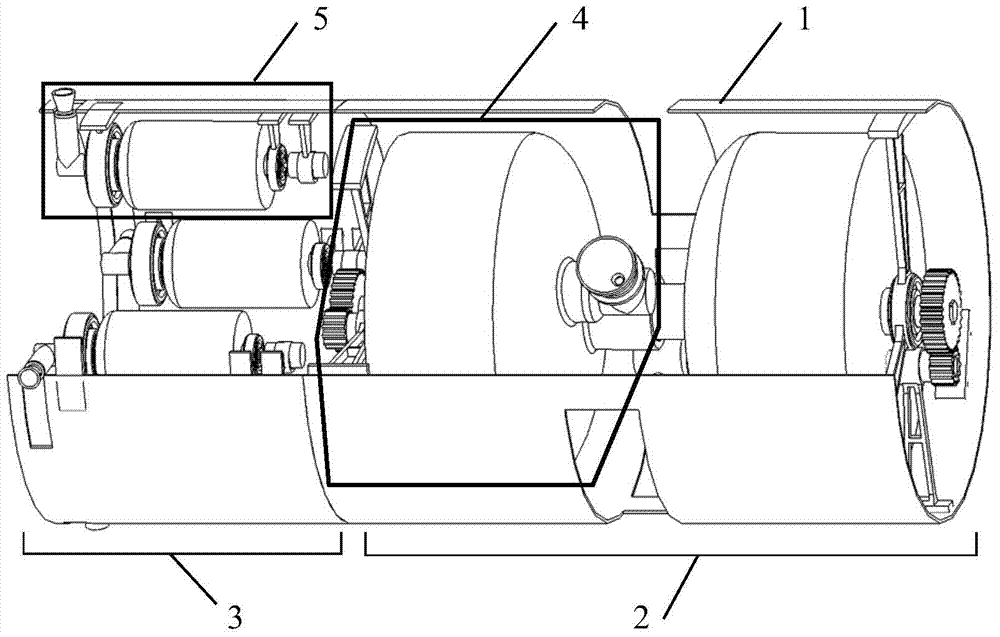

[0039] The present invention is a kind of rotation control solid state orbit control engine, such as figure 1 As shown, it includes an aircraft outer shell 1, an orbit control power system 2 and an attitude control power system 3.

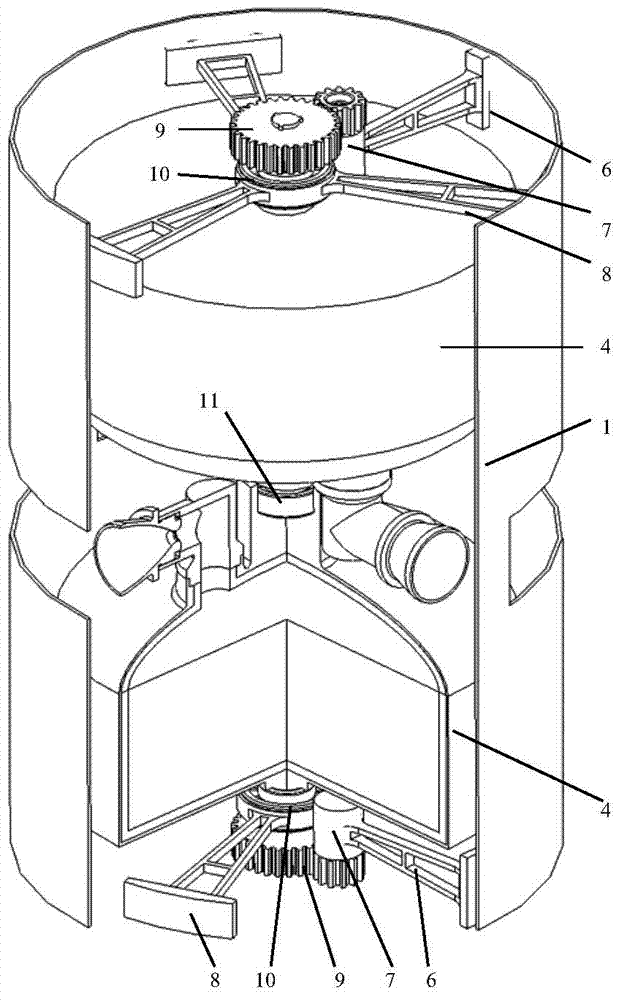

[0040] Such as figure 2 As shown, the orbital control power system 2 includes two orbital control engines 4;

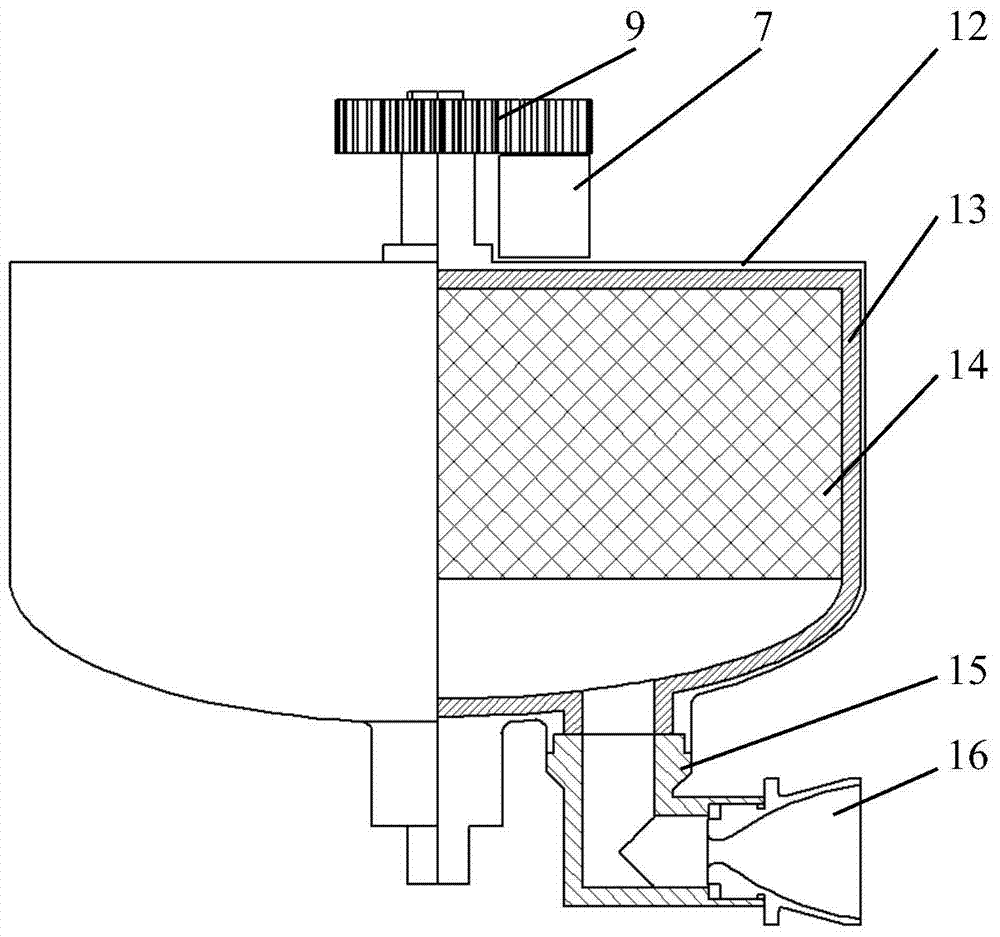

[0041] Orbital control engine 4 such as image 3 As shown, it includes a rail control engine casing 12, a rail control engine heat insulation layer 13, a rail control engine powder column 14, a rail control gas 90-degree pipeline 15, and a rail control engine nozzle 16;

[0042] Same as conventional solid rocket motors, between the orbital control engine housing 12 and the orbital control engine insulation layer 13, between the orbital control engine insulation layer 13 and the orbital control engine charge co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com