Cooperative-control CFB (Circulating Fluidized Bed) boiler in-furnace desulphurization and denitration burning system and cooperative-control CFB boiler in-furnace desulphurization and denitration burning method

A technology of desulfurization, denitrification, and coordinated control, applied in the direction of combustion method, combustion type, combustion equipment, etc., can solve the problems of limited use, difficulty in achieving simultaneous emission reduction, and inability to adapt to environmental protection needs, so as to inhibit the generation and reduce the content of desulfurizer , Increase the effect of material concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

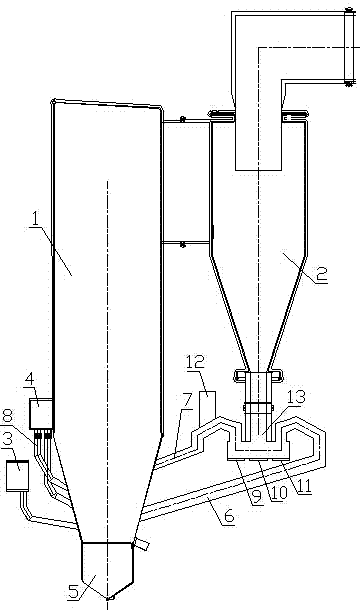

[0010] Below in conjunction with accompanying drawing, the present invention is described in further detail.

[0011] Such as figure 1 As shown, the combustion system for coordinated control of desulfurization and denitrification in the CFB boiler furnace of the present invention includes a furnace 1, a coal inlet 3, a primary air chamber 5, a secondary air box 4, two secondary air pipes 8, a cyclone separator 2, Feeding mechanism 13, connecting feeding mechanism 13 and the upper layer feeding pipe 7 and the lower layer feeding pipe 6 of the furnace 1, the end of the upper layer feeding pipe 7 is higher than the end of the lower layer feeding pipe 6, the upper layer feeding pipe 7 is connected to the The dilute-phase area between the feeding mechanism 13 and the furnace 1, the lower layer return pipe 6 connects the dense-phase area between the feeding mechanism 13 and the furnace 1, and three returning bellows 9, 10, 11 are arranged at the lower end of the feeding mechanism 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com