High-hardness central-tube-strengthened ratproof optical cable and manufacturing technology thereof

A central tube and high-hardness technology, which is applied to the high-hardness central tube-reinforced rodent-proof optical cable and its manufacturing process field, can solve the problems of communication loss, the rodent-proof performance of tight-fitting optical fibers cannot reach the full-section rodent-proof, etc. Convenient and fast, obvious anti-rat bite and anti-squashing performance, and the effect of convenient promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

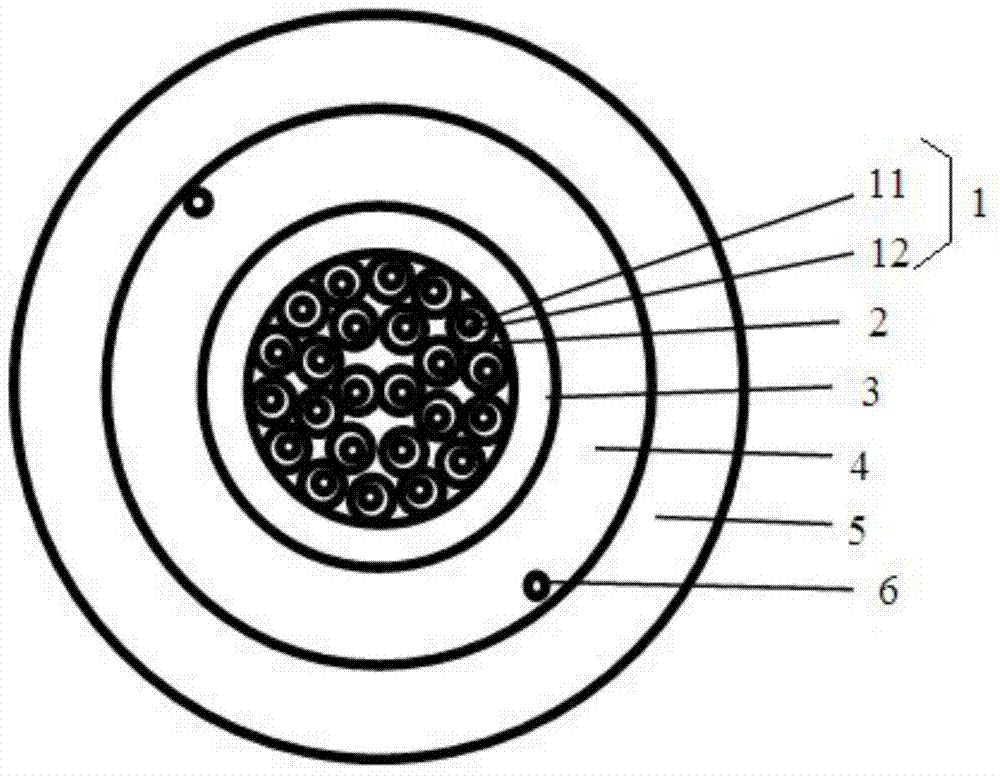

[0037] This embodiment discloses a high-hardness central tube reinforced anti-rat optical cable, the cross-sectional structure of which is as follows figure 1 As shown in , it includes from inside to outside: several tight-buffered optical fibers 1, central tube 3, glass fiber yarn 4 and outer sheath 5, the above-mentioned central tube 3 covers the above-mentioned tight-buffered optical fiber 1, and the inside of the above-mentioned central tube 3 is filled with Water-blocking material 2, the above-mentioned glass fiber yarn 4 is evenly arranged in the circumferential direction of the outer layer of the above-mentioned central tube 3, the above-mentioned outer sheath is arranged on the outer layer of the above-mentioned glass fiber yarn, and the above-mentioned outer sheath is made of high hardness low-smoke halogen-free flame-retardant polymer Olefin sheath.

[0038] The tight-buffered optical fiber 1 is composed of an optical fiber 11 coated with a tight-buffered layer 12, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com