Preparation method for large-format organic photoconductive drum and organic photoconductive drum prepared with preparation method

An organic photoconductive drum and large-format technology, applied in optics, electrical recording, instruments, etc., can solve the problems of high manufacturing cost, large volume of dip coating tank, and difficulty in controlling the uniformity of material liquid circulation in the tank. The effect of less investment and simple process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] The preparation method of the large-format organic photoconductive drum of the present invention adopts a low-pressure atomization film-forming method, comprising the following steps:

[0016] ① Spray the pre-coating paint on the large-format organic photoconductor drum base. The preparation method of the pre-coating paint is: dissolve nylon resin and solvent at a mass ratio of 1:25-50;

[0017] ② After the pre-coating is fully dried, spray the charge generating coating. The preparation process of the charge generating coating is: mix Y-type phthalocyanine titanium oxide, polyvinyl butyral resin, and solvent by 1:(0.5-1.5):(200- The mass ratio of 300) is uniformly dispersed by ball milling;

[0018] ③ After the charge generation layer is fully dried, spray the charge transport material. The preparation method of the charge transport material: dissolve styryl triphenylamine, polycarbonate resin, and solvent at a mass ratio of 1:(0.8-1.3):(30-50) to prepare made.

[001...

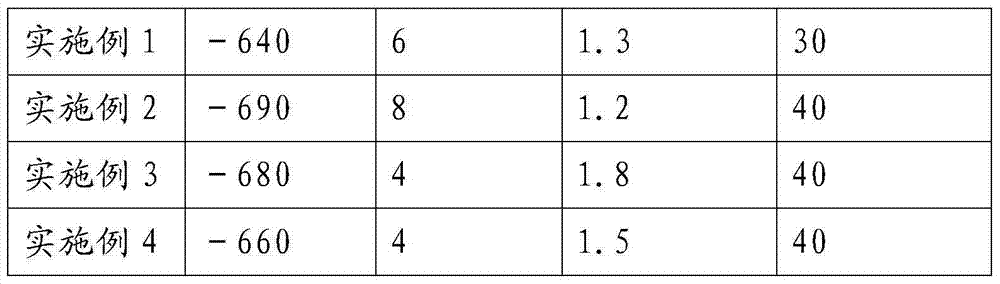

Embodiment 1

[0021] Example 1: ① Preparation and spraying of pre-coating paint: Dissolve 25g of nylon resin GM-8000 in a mixed solvent of 400ml of n-butanol and 600ml of methanol to make a spraying liquid, and spray on the drum base to form a pre-coating. The organic photoconductor drum was baked in a drying oven at 100° C. for 10 minutes. ② Preparation and spraying of charge generating layer paint: Disperse 5g of charge generating material Y-TiOPc, 5g of polyvinyl butyral resin, 100ml of cyclohexanone, and 1500ml of methyl ethyl ketone into a uniform spraying liquid by ball milling, and spray on the drum base A charge generating layer is formed. The organic photoconductor drum was baked in a drying oven at 100° C. for 10 minutes. ③Charge transport layer paint preparation and spraying: 20g of styryl triphenylamine, 20g of polycarbonate resin PCZ-300, 100ml of cyclohexanone, and 900ml of toluene were prepared as a spraying liquid, and sprayed on the drum base to form a charge transport lay...

Embodiment 2

[0023] Embodiment 2: Except that during spraying, the drum base rotating speed is set at 300 rpm, and the reciprocating speed of the spray gun is set at 20mm / sec, all the other formulas and steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com