Radiating device of electronic element

A heat dissipation device and electronic component technology, which is applied in the direction of cooling/ventilation/heating transformation, etc., can solve the problems of high junction temperature of heating elements, aging service life of phosphor powder, and drift of main wavelength of light emission, etc. Stable performance and high cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

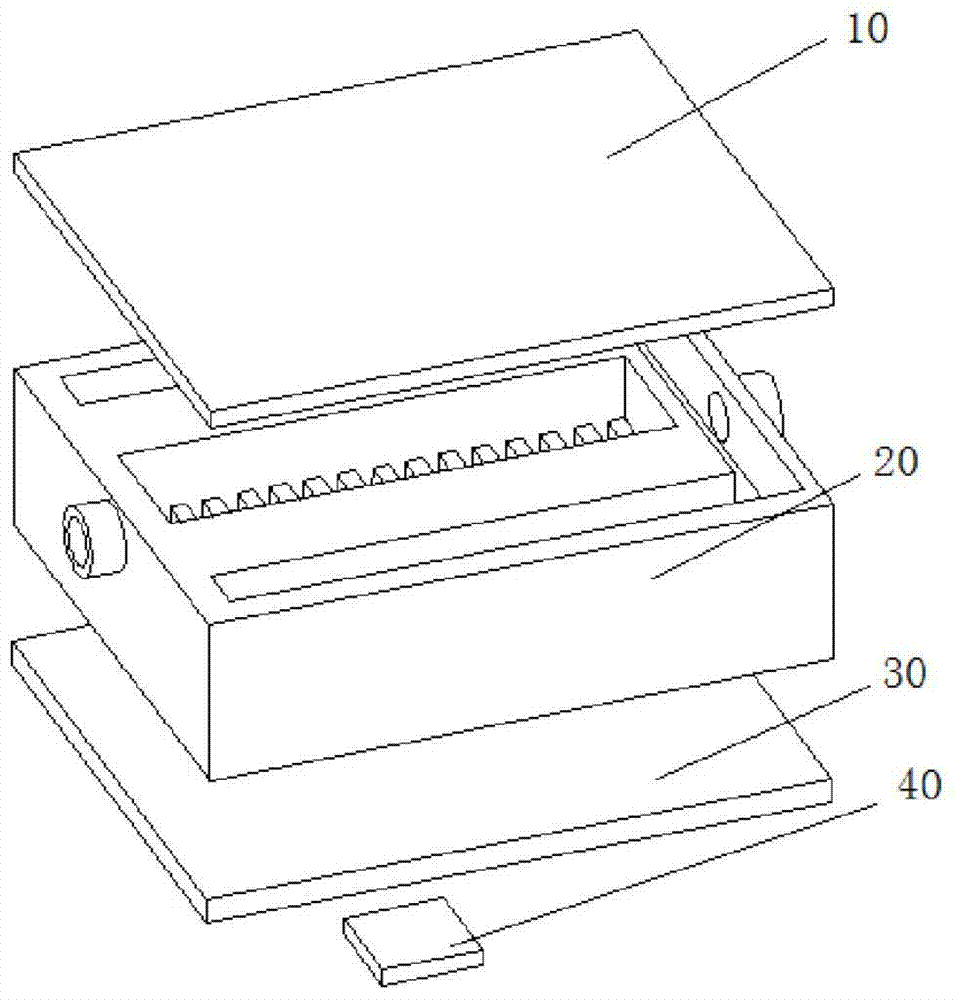

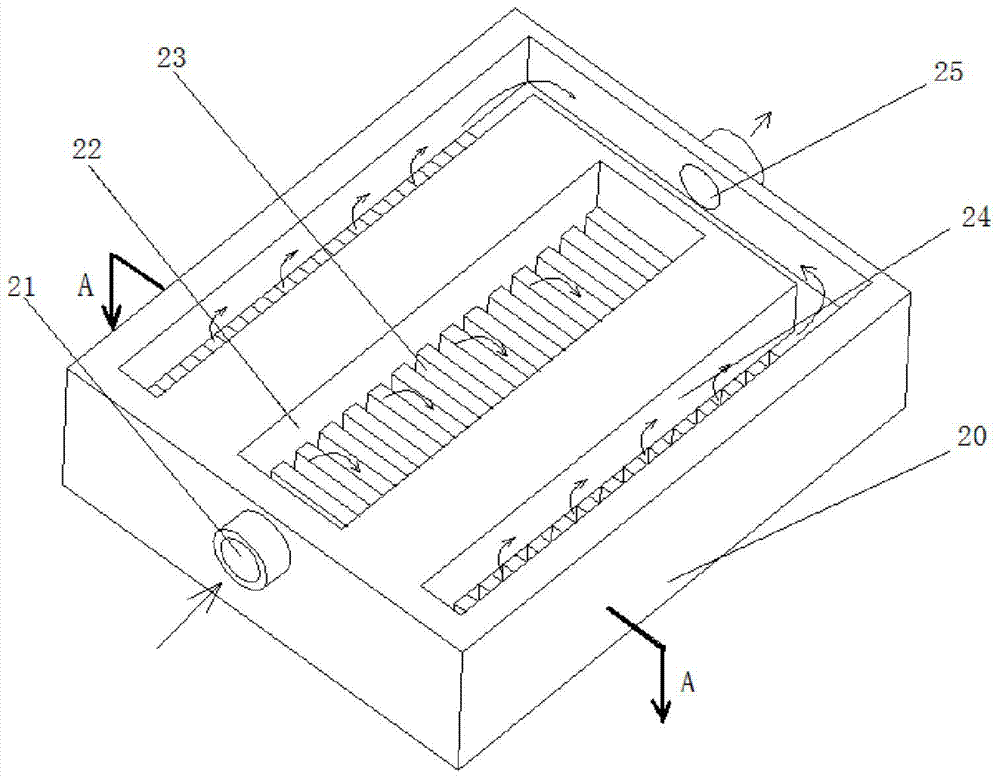

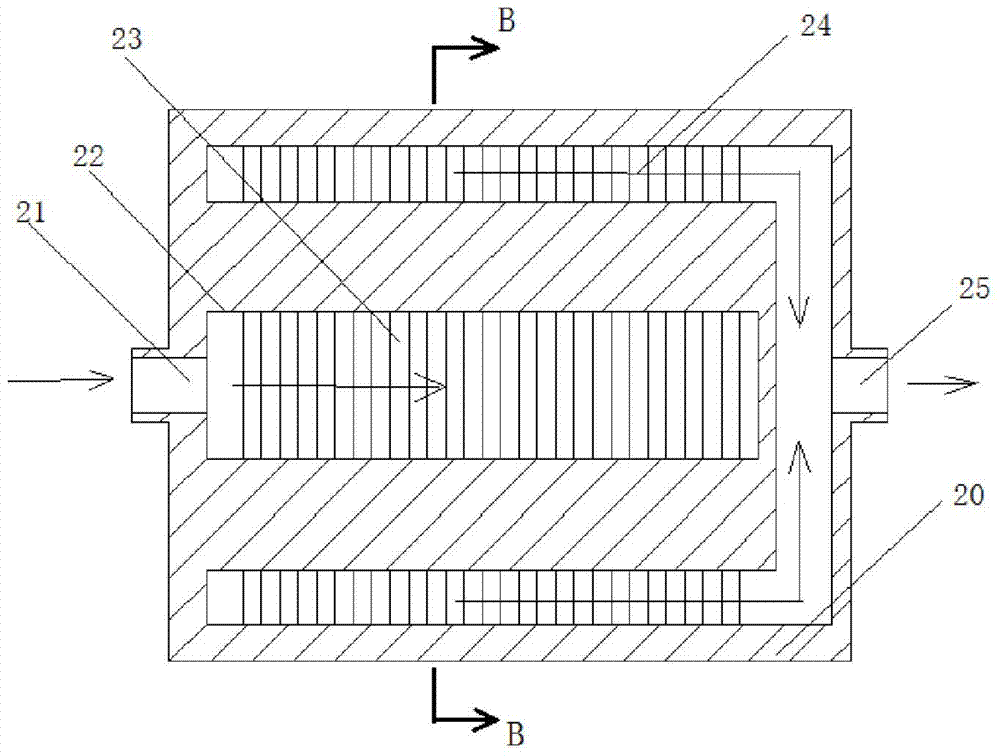

[0025] Such as figure 1 The heat dissipation device for the electronic components shown is composed of an upper substrate 10, a microgroove group heat sink 20, and a lower substrate 30. The shape of the microgroove group heat sink is a box with an upper opening, and the upper substrate 10 is located above the microgroove group heat sink. , is fixedly connected with the heat sink 20 of the micro-groove group to form a sealing structure, which can seal and protect the heat sink 20 of the micro-groove group; the lower substrate 30 and the lower surface of the heat sink 20 of the micro-groove group are bonded by thermal silica The material of the lower substrate 30 is silicon or heat-conducting metal, which is a transition body for heat transmission. The heat-conducting silic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com