Processing method of thermoplastic filament composite material excrement leaking plate

A thermoplastic long fiber and processing method technology, applied in the field of animal husbandry, can solve the problems of large resistance to manure and unclean scraping, and achieve the effects of liberating labor, improving production efficiency and shortening production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

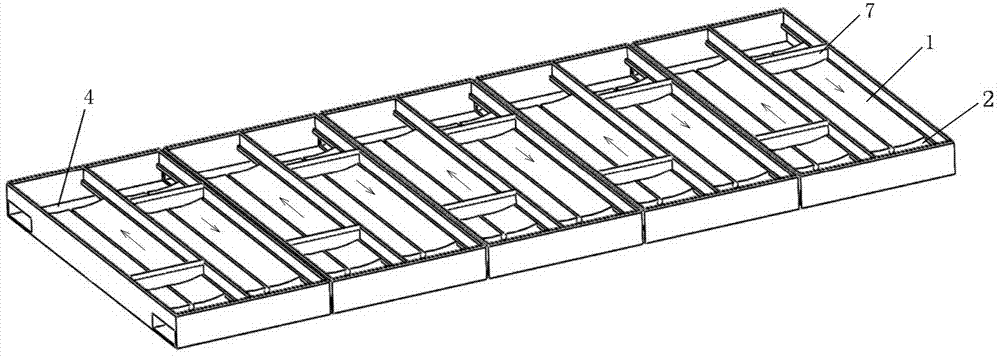

[0137] Embodiment 1: as figure 1 with figure 2 The shown polymer composite excrement collection device includes a manure leaking tank 1 and a manure collecting tank. The manure leaking tank 1 and the manure collecting tank are composed of two juxtaposed tanks with four-sided borders. The inner edge of each tank structure A manure leaking tank 1 is arranged horizontally, and a urine leaking tank is provided at the bottom of the manure collecting tank, and the left or right side of the bottom of the manure leaking tank 1 is inclined to the urine leakage slot; the front end of the manure leaking tank 1 is higher than the rear end, and the manure leaking tank 1 The front and rear ends are respectively provided with a feces collection tank and a urine collection tank, and the manure collection tank and the urine collection tank are all lower than the end of the leaking manure tank 1; The urinal has an integrated structure made of resin-based reinforced composite material, or an ...

Embodiment 2

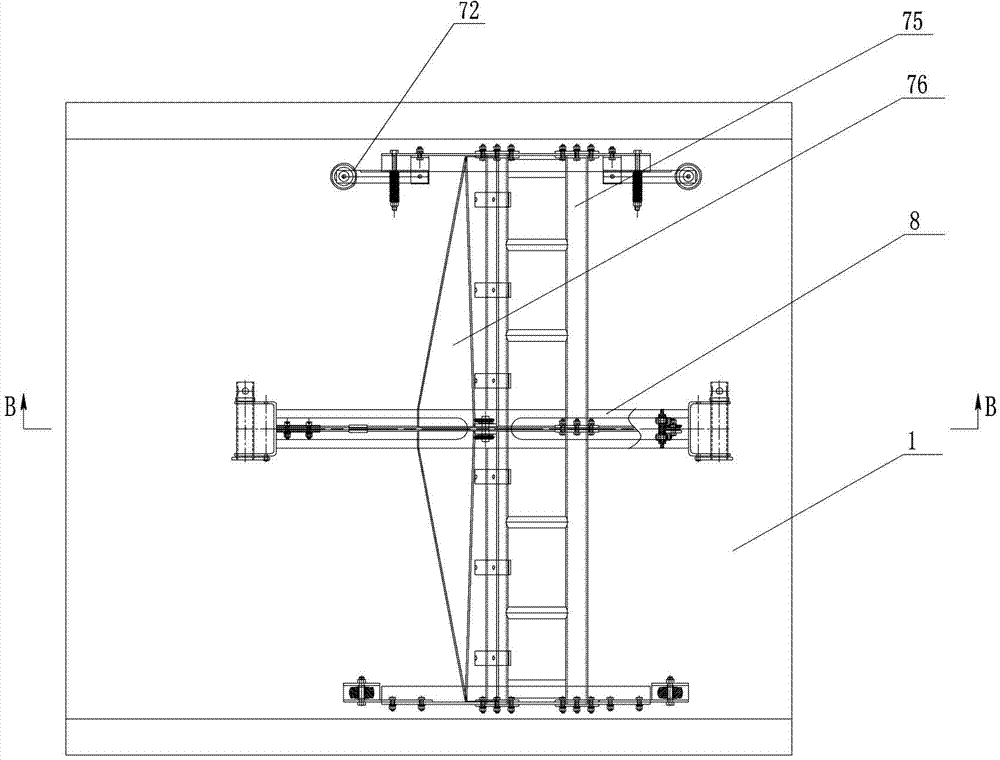

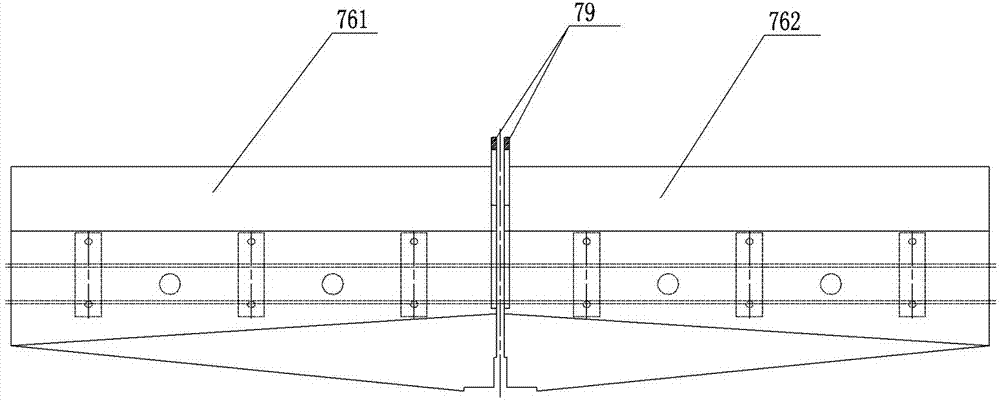

[0142] Example 2: see figure 1 , figure 2 , image 3 , Figure 7 with Figure 8 , another kind of structure is to arrange the leaking manure tank scraping device 70 on the leaking manure tank 1, the movable manure scraping plate 76 is installed at the lower end of the leaking manure tank scraping device 70; the lower edge of the movable manure scraping plate 76 is connected with the drain The bottom surface of the manure tank 1 matches, and is also in shapes such as an arc or an inclined plane. The structural form of the dung leakage tank scraper 7 can be the structure that only scraper is formed, for example Figure 10 with Figure 11 The movable dung scraper 76 shown that can be adjusted includes a left scraper 761 and a right scraper 762 . The two ends of the leakage manure tank 1 are respectively provided with longitudinal manure collection tanks 2, and the two juxtaposed manure collection tanks of groove structure are connected. After adopting above-mentioned exc...

Embodiment 3

[0145] Embodiment 3: there is at least one manure leaking tank 1, and it can be a plurality of juxtaposed ones, such as figure 1 shown. The bottom of the manure leaking tank 1 matches the urine leaking tank 3, and the bottom surface of the manure leaking tank 1 is an arc surface, or it can be a lower step surface in the middle, or a wave surface, or an inverted triangle shape. There are at least two manure leaking tanks 1 arranged side by side, and a plurality of manure leaking tanks 1 can be connected intermittently or continuously side by side. Both sides of the manure leakage tank 1 are provided with guide rails 5 integrated therewith. The manure leaking tank 1 is provided with a manure leaking tank scraper 6 made of thermosetting or thermoplastic reinforced composite material or metal, and the manure leaking tank scraper 6 is installed on the guide rails 5 on both sides of the manure leaking tank 1 . The manure collecting tank 2 is provided with a through hole consisten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com