Fragrant and spicy caviar and production method thereof

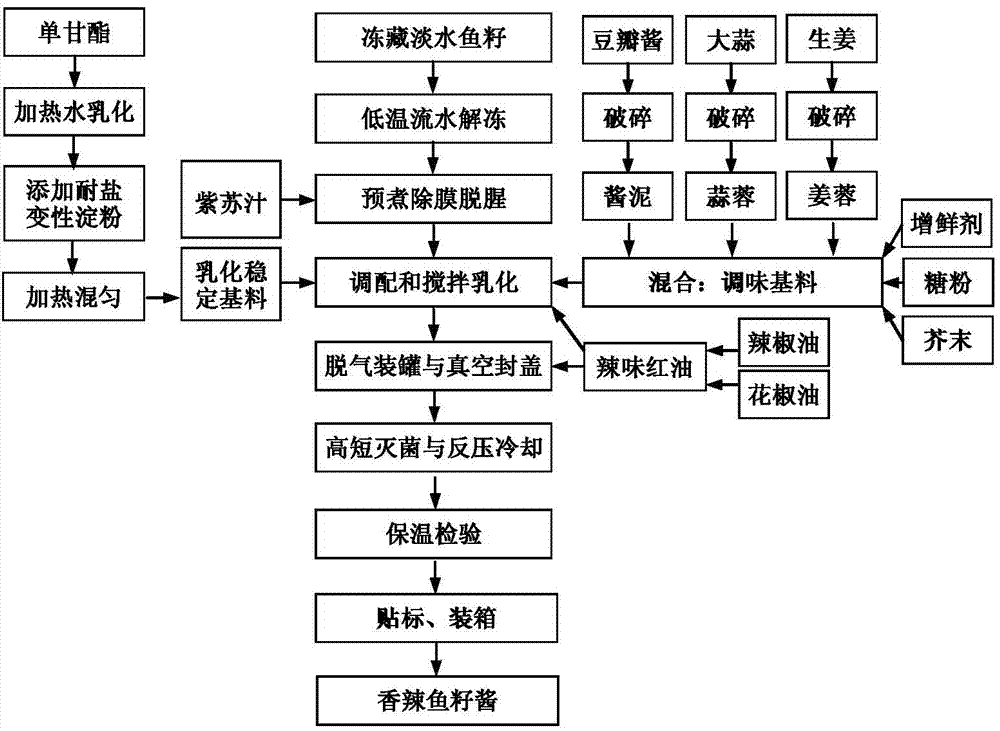

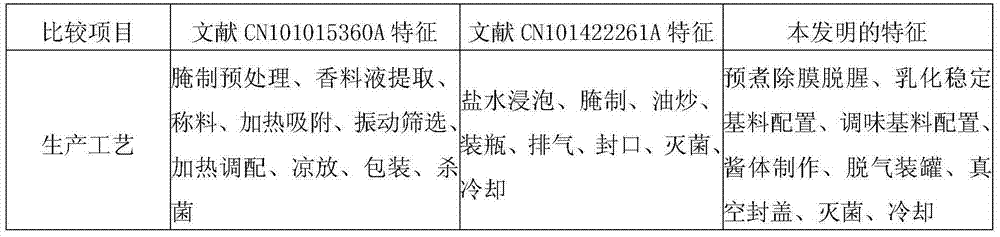

A technology for spicy fish and fish roe, which is applied to the field of spicy fish roe sauce and its production, can solve the problems of hardened fish roe taste, aggravated fishy smell, increased energy consumption, etc., and achieves a simplified blending process and plump fish roe particles. , the effect of maintaining integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

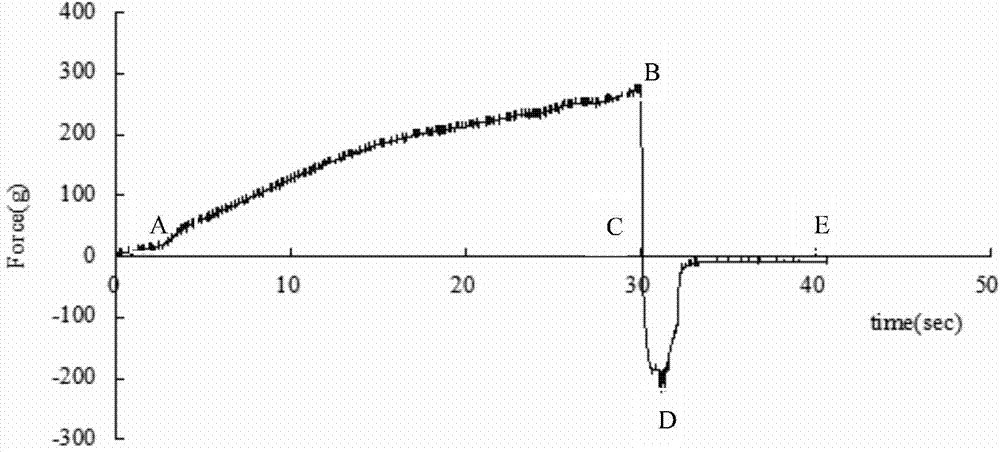

Method used

Image

Examples

Embodiment 1

[0059] Embodiment 1: a kind of making embodiment 1 of spicy caviar

[0060] A spicy caviar product, which uses fresh or frozen freshwater fish roe as raw material, wherein the frozen roe is first placed at 4°C to naturally thaw the roe, so that the center temperature of the roe reaches 0°C As the end point of thawing, the fish roe is taken out and drained, and it is made by precooking to remove the membrane and deodorization, sauce preparation, degassing and filling, vacuum sealing, high and short sterilization, back pressure water cooling, heat preservation inspection and other processes. Spicy caviar products. The optimal ratio in terms of physical quantity is as follows:

[0061] Fish roe 100kg, chili oil 16kg, pepper oil 3kg, freshness enhancer 4kg, sugar powder 6.5kg, cross-linked hydroxypropyl waxy corn starch 3kg, monoglyceride 0.4kg, bean paste 20kg, minced ginger 15kg, minced garlic 7kg, Mustard 0.5kg, water 10kg;

[0062] Produced as follows:

[0063] (1) Caviar ...

Embodiment 2

[0078] Embodiment 2: a kind of making embodiment 2 of spicy caviar

[0079] According to the basic process step of embodiment 1, the proportioning of each composition in the present embodiment is as follows according to the physical quantity:

[0080] Fish roe 100kg, chili oil 15kg, pepper oil 3kg, freshness enhancer 3kg, sugar powder 6kg, cross-linked hydroxypropyl waxy corn starch 4kg, monoglyceride 0.3kg, bean paste 20kg, minced ginger 16kg, minced garlic 5kg, mustard 0.4kg, water 10kg;

Embodiment 3

[0081] Embodiment 3: a kind of making embodiment 3 of spicy caviar

[0082] According to the basic process step of embodiment 1, the proportioning of each composition in the present embodiment is as follows according to the physical quantity:

[0083] 100kg fish roe, 17kg chili oil, 4kg pepper oil, 5kg freshener, 7kg sugar powder, 5kg cross-linked hydroxypropyl waxy corn starch, 0.5kg monoglyceride, 18kg bean paste, 14kg minced ginger, 8kg minced garlic, mustard 0.6kg, water 11kg;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com