Mud-resistant low-smoke zero-halogen flame-retardant cross-linked polyolefin sheathed rubber material and preparation method thereof

A technology of cross-linking polyolefin and sheath rubber, applied in the field of chemical engineering, can solve the problems of instability, low content of polar groups, high price, etc., achieve good oil resistance and mud resistance, meet the flame retardant performance, The effect of easy installation and laying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

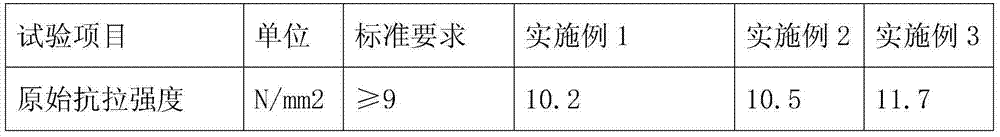

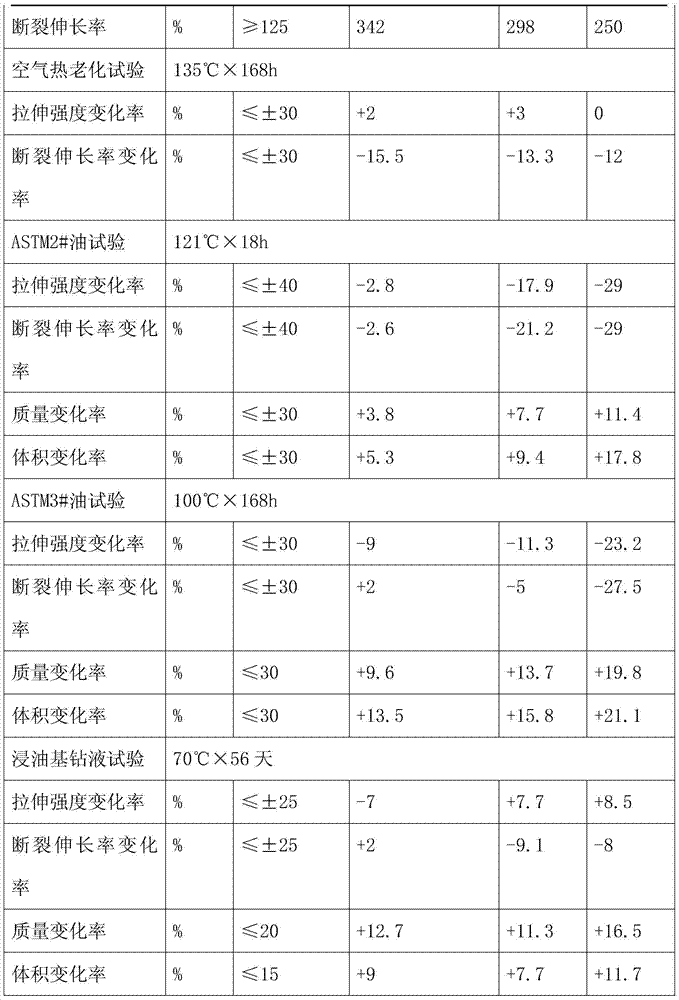

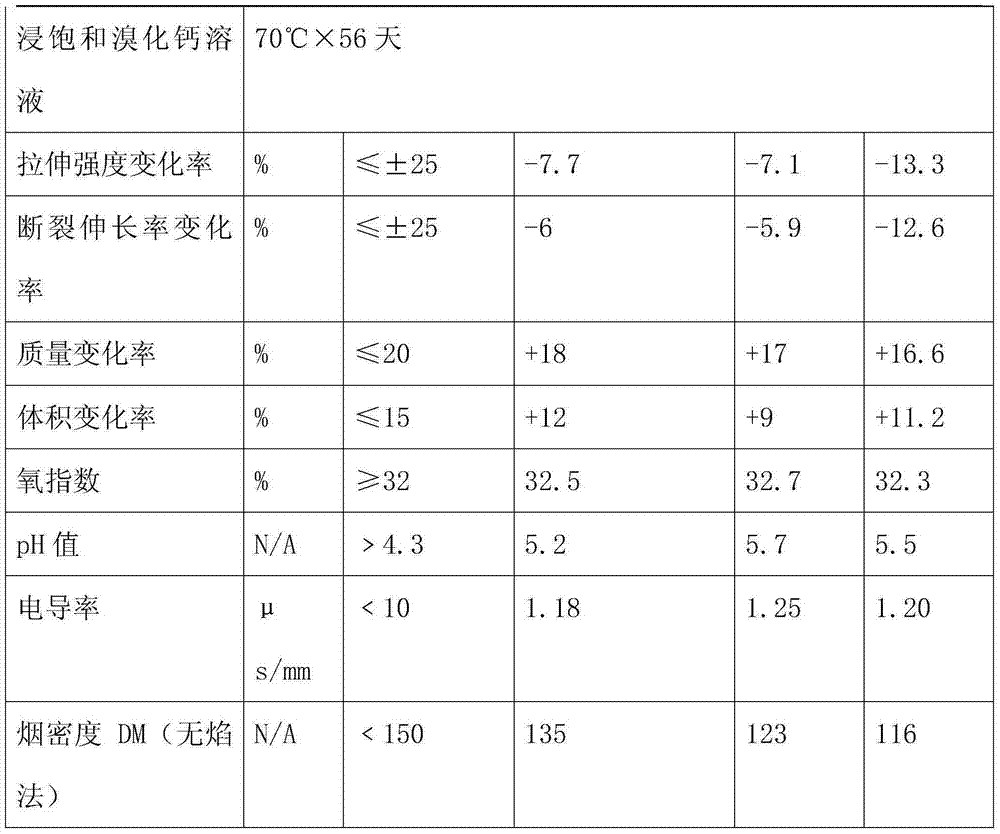

Embodiment 1

[0034] A mud-resistant low-smoke halogen-free flame-retardant cross-linked polyolefin sheath rubber material, including 100 parts of ethylene-vinyl acetate copolymer, 100 parts of magnesium hydroxide, 40 parts of white carbon black, 2,2,4-trimethyl 1 part of 1,2-dihydroquinoline polymer, 1.5 parts of vinyl silane, 2 parts of dicumyl peroxide, and 2 parts of triallyl isocyanurate.

Embodiment 2

[0036] A mud-resistant low-smoke halogen-free flame-retardant cross-linked polyolefin sheath rubber material, including 85 parts of ethylene-vinyl acetate copolymer, 15 parts of EPDM rubber, 75 parts of magnesium hydroxide, 75 parts of aluminum hydroxide, 20 parts of carbon black N300, 2 parts of 2,2,4-trimethyl-1,2-dihydroquinoline polymer, 2 parts of vinyl silane, 3 parts of dicumyl peroxide, triallyl isocyanurate 3 parts of acid ester.

Embodiment 3

[0038] A mud-resistant low-smoke halogen-free flame-retardant cross-linked polyolefin sheath rubber material, including 70 parts of ethylene-vinyl acetate copolymer, 30 parts of EPDM rubber, 160 parts of aluminum hydroxide, 2,2,4- 2.5 parts of trimethyl-1,2-dihydroquinoline polymer, 3 parts of vinyl silane, 5 parts of dicumyl peroxide, and 3 parts of N,N'-m-phenylene bismaleimide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com