Ceramic inkjet printing ink and method with adjustable penetration depth

A ceramic inkjet and printing ink technology, applied in inks, household appliances, applications, etc., can solve the problems of uncontrollable penetration direction, no decorative effect, difficult to achieve decorative effect, etc., to achieve good inkjet printing performance, various Low anisotropy and strong stereoscopic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

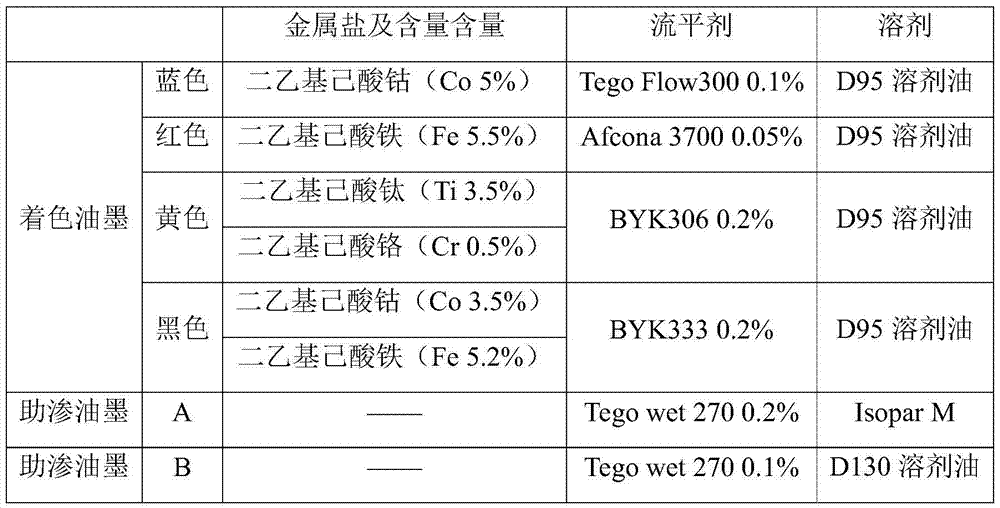

Embodiment 1

[0056]

[0057] Among them, the viscosity of the bleed ink A is 3.2mPa s, and the surface tension is 23.0mN / m; the viscosity of the bleed ink B is 5.7mPa s, and the surface tension is 26.7mN / m.

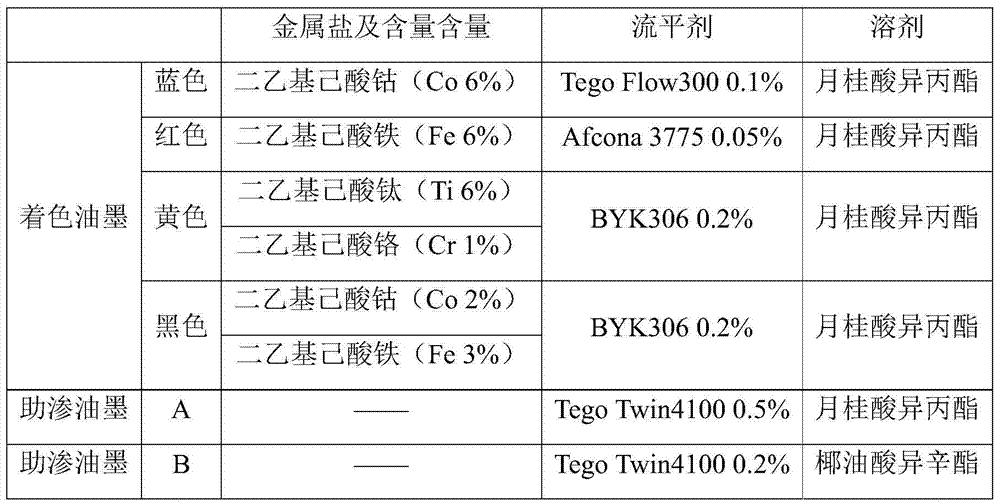

Embodiment 2

[0059]

[0060] Among them, the viscosity of the bleed ink A is 3.6mPa s, and the surface tension is 25.1mN / m; the viscosity of the bleed ink B is 7.5mPa s, and the surface tension is 28.1mN / m.

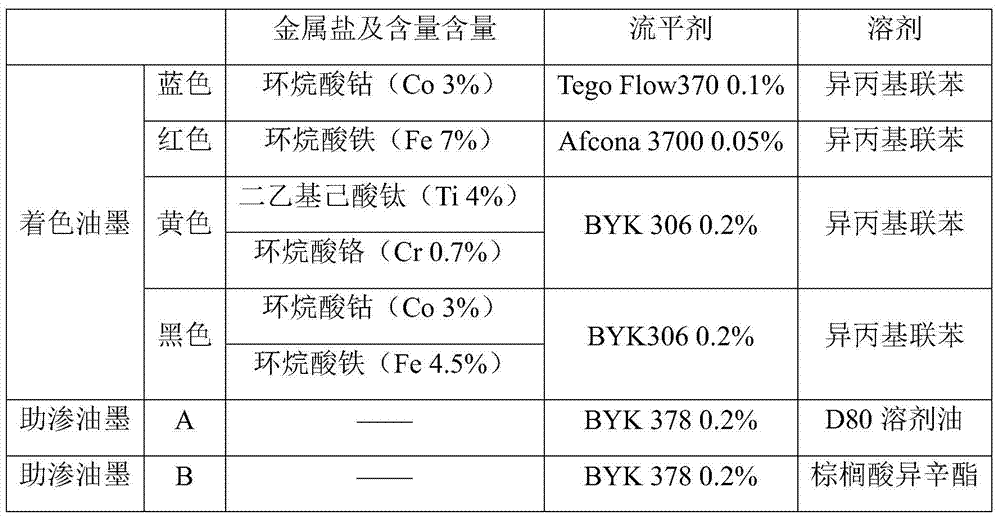

Embodiment 3

[0062]

[0063] Among them, the viscosity of the bleed ink A is 1.5mPa s, and the surface tension is 24.5mN / m; the viscosity of the bleed ink B is 9.8mPa s, and the surface tension is 30.0mN / m.

[0064] Its application method includes the following steps:

[0065] (1) Each independent ink is loaded into six channels of the inkjet printer;

[0066] (2) Decorate the colored ink on the surface of the ceramic body or the ceramic body containing the glaze by inkjet printing; then print the ink to promote penetration;

[0067] (3) After the inkjet printed ceramic material is dried, it is calcined in a kiln at 1000-1300°C;

[0068] (4) Polishing the surface of the calcined ceramic tile product to obtain a ceramic tile with a three-dimensional decorative pattern.

[0069] In particular, this ink is suitable for printing on fabrics that do not contain calcium, magnesium, barium, zinc or their contents are extremely low. The fabric can be applied to the ceramic body by dry powder c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com