Preparing method for gelatin microsphere of fixed alcohol dehydrogenase by micro-porous membrane permeation and emulsification

A technology of alcohol dehydrogenase and microporous membrane, which is applied in the direction of fixation on/in the organic carrier, can solve the problem of wide particle size distribution of microspheres, and achieve simple and easy preparation process, mild preparation conditions, and fixed powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

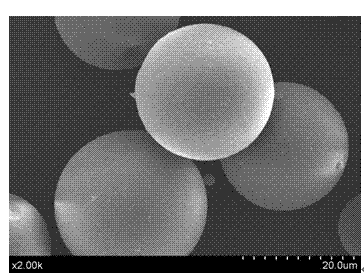

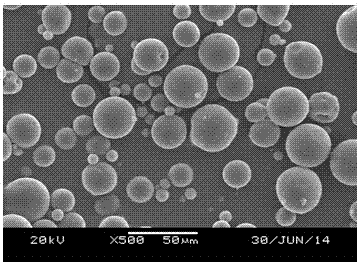

[0026] Preparation of gelatin microspheres immobilized with alcohol dehydrogenase by membrane emulsification method:

[0027] Under the condition of magnetic stirring at 200 rpm and temperature at 55°C, add 1 gram of dry gelatin powder to 10 ml of water, and maintain magnetic stirring at this speed for 0.5 hours until the dry powder of gelatin is completely dissolved in water, and the concentration of gelatin after dissolution is 0.1 g / Milliliter, add 1 milligram of alcohol dehydrogenase to this gelatin solution, the concentration of alcohol dehydrogenase after dissolving is 0.1 mg / ml. The above gelatin / alcohol dehydrogenase aqueous solution was used as the aqueous phase.

[0028] The oil-soluble emulsifier Span-80 is added to 60 ml of liquid paraffin, and the quality of Span-80 is 1.5% of that of the liquid paraffin. Stir magnetically at a speed of 200 rpm for 30 minutes until Span-80 is completely dissolved, and heat the above solution to 60° C. as the oil phase.

[0029]...

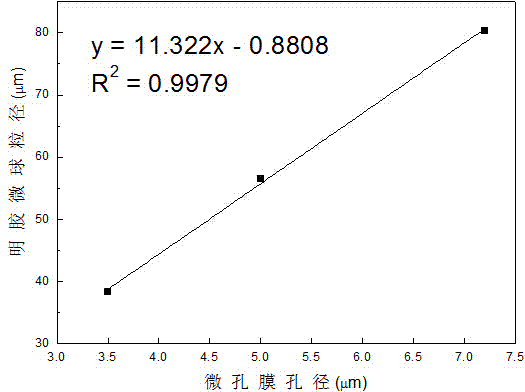

Embodiment 2

[0037] The preparation process of this example is the same as that of Example 1, except that the microporous membrane with a membrane pore size of 3.5 microns is replaced by a microporous membrane with a membrane pore size of 5.0 microns to obtain a gelatin microporous membrane immobilized with alcohol dehydrogenase. The particle size and distribution of the balls are shown in Table 1.

Embodiment 3

[0039] The preparation process of this example is the same as that of Example 1, except that the microporous membrane with a membrane pore size of 3.5 microns is replaced by a microporous membrane with a membrane pore size of 7.2 microns to obtain a gelatin microporous membrane immobilized with alcohol dehydrogenase. The particle size and distribution of the balls are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com