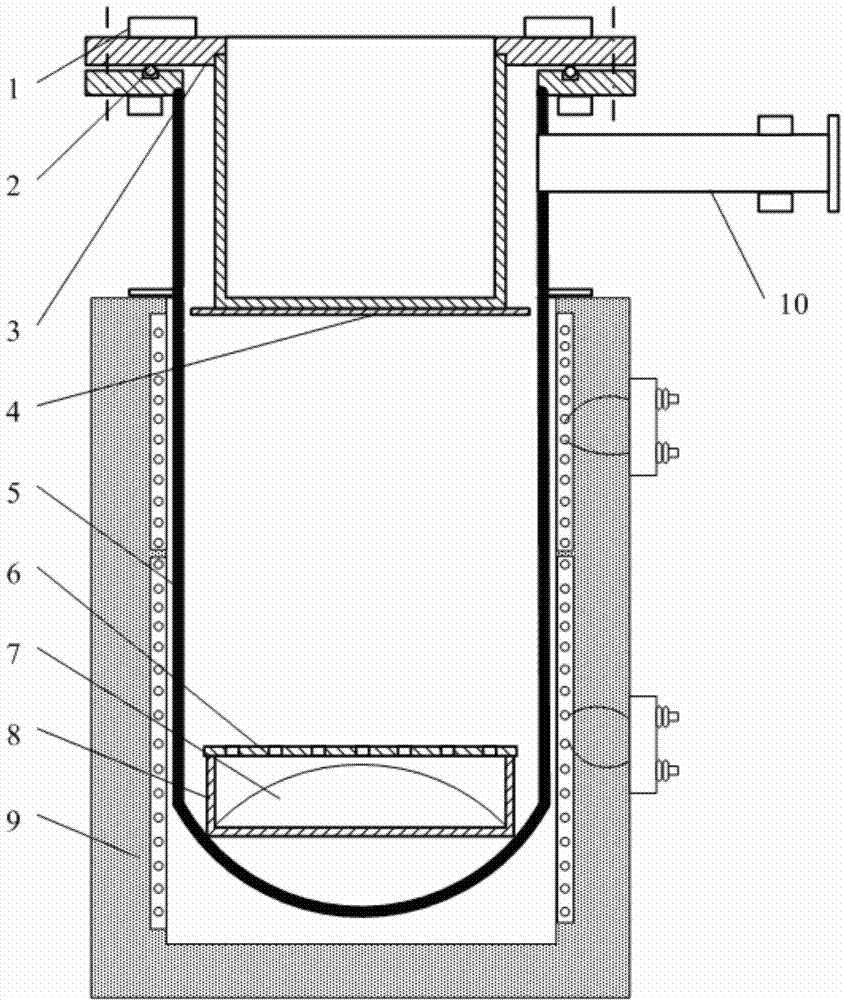

High-purity calcium vacuum distillation purification device and method

A purification method and vacuum technology are applied in the field of high-purity calcium vacuum distillation and purification devices, which can solve the problems of unstable quality and low purity of batch products, and achieve the effects of stable batch product quality, stable distillation rate and good separation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Adopt high-purity calcium vacuum distillation purification device of the present invention, carry out high-purity calcium vacuum distillation purification, its steps are as follows:

[0046] 1) System pressure rise rate test: ensure that the system pressure rise rate is 0.6Pa / h. If the pressure rise rate of the system is high, the distillation unit needs to be checked for leaks.

[0047]2) Furnace installation: In a drying room environment with room temperature and humidity 99%, and the impurity content is shown in Table 1.

[0048] 3) Dehydration and degassing: Connect the vacuum system, turn on the rotary vane mechanical pump and the cooling water circulation system, when the vacuum degree of the system is -3 ~10 -2 Pa, close the vacuum butterfly valve, and energize the upper and lower resistance wires of the heating furnace at the same time. Control the current to raise the temperature of the reaction tank to 200°C within 1 hour, and keep it at 200°C for 0.5 hours ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com