Surface treatment method for forming micro-porous structure on surface of aluminum alloy

A technology of aluminum alloy surface and microporous structure, which is applied in the field of surface treatment to form a microporous structure on the surface of aluminum alloy, can solve the problems of time-consuming and laborious, cannot be effectively and quickly removed, and achieve enhanced affinity, good roughness, and increased The effect of cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A surface treatment method for forming a microporous structure on the surface of an aluminum alloy, comprising the steps of: putting the aluminum alloy into a tank filled with pickling liquid for pickling treatment, the pickling liquid includes 50Kg of hydrochloric acid, 10Kg of diammonium hydrogen phosphate, Hexamethylenetetramine 0.1Kg, add water to dilute to 1000L, pickle at room temperature for 5 minutes, wash off raw material scale and rust; Rinse in the second water tank, rinse the scale and pickling solution; put the rinsed aluminum alloy into a tank filled with an amine aqueous solution for immersion treatment. The amine aqueous solution includes 20Kg of ethylenediamine, 1Kg of tolyltriazole, Add 5Kg of aniline, dilute to 1000L with water, impregnate at 65°C for 8 minutes; put the impregnated aluminum alloy into the third water pool with pH 5 to rinse, and rinse the residual amine-based aqueous solution.

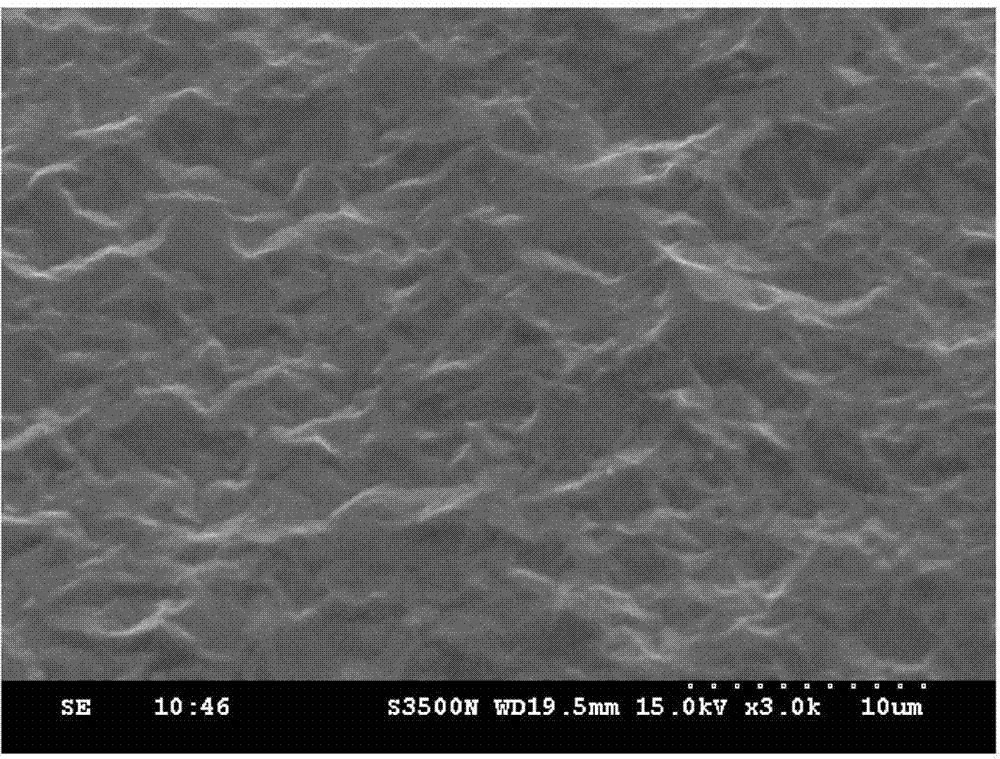

[0029] Utilize the scanning electron microscope to obser...

Embodiment 2

[0031] A surface treatment method for forming a microporous structure on the surface of an aluminum alloy, comprising the steps of: putting the aluminum alloy into a tank filled with pickling liquid for pickling treatment, the pickling liquid includes 70Kg of hydrochloric acid, 15Kg of diammonium hydrogen phosphate, Hexamethylenetetramine 0.2Kg, add water to dilute to 1000L, pickle at room temperature for 7 minutes, wash off raw material scale and rust; Rinse in the second water tank, rinse the scale and pickling solution; put the rinsed aluminum alloy into a tank filled with an amine aqueous solution for immersion treatment. The amine aqueous solution includes 20Kg of ethylenediamine and 10Kg of tolyltriazole , 5Kg of aniline, diluted with water to 1000L, dipped at 70°C for 10 minutes; rinsed the impregnated aluminum alloy in a third pool with a pH of 6, and rinsed away the residual amine-based aqueous solution.

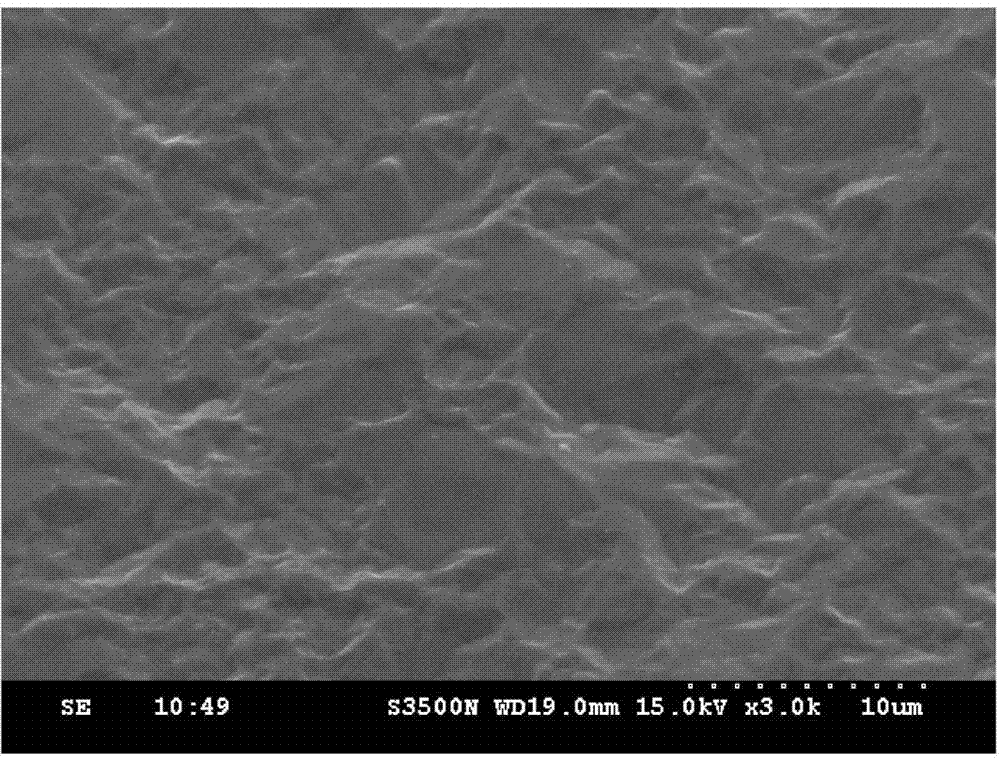

[0032] Utilize the scanning electron microscope to observe and...

Embodiment 3

[0034] A surface treatment method for forming a microporous structure on the surface of an aluminum alloy, comprising the steps of: putting the aluminum alloy into a tank filled with pickling liquid for pickling treatment, the pickling liquid includes 90Kg of hydrochloric acid, 20Kg of diammonium hydrogen phosphate, Hexamethylenetetramine 0.3Kg, add water to dilute to 1000L, pickle at room temperature for 9 minutes, wash off raw material scale and rust; Rinse in the second water tank, rinse the scale and pickling solution; put the rinsed aluminum alloy into a tank filled with an amine aqueous solution for immersion treatment, the amine aqueous solution is ethylenediamine 30Kg, tolyltriazole 4Kg, aniline 5Kg, add water to dilute to 1000L, impregnate at 75°C for 12 minutes; put the impregnated aluminum alloy into the third water pool with pH 7 to rinse, and rinse off the residual amine-based aqueous solution.

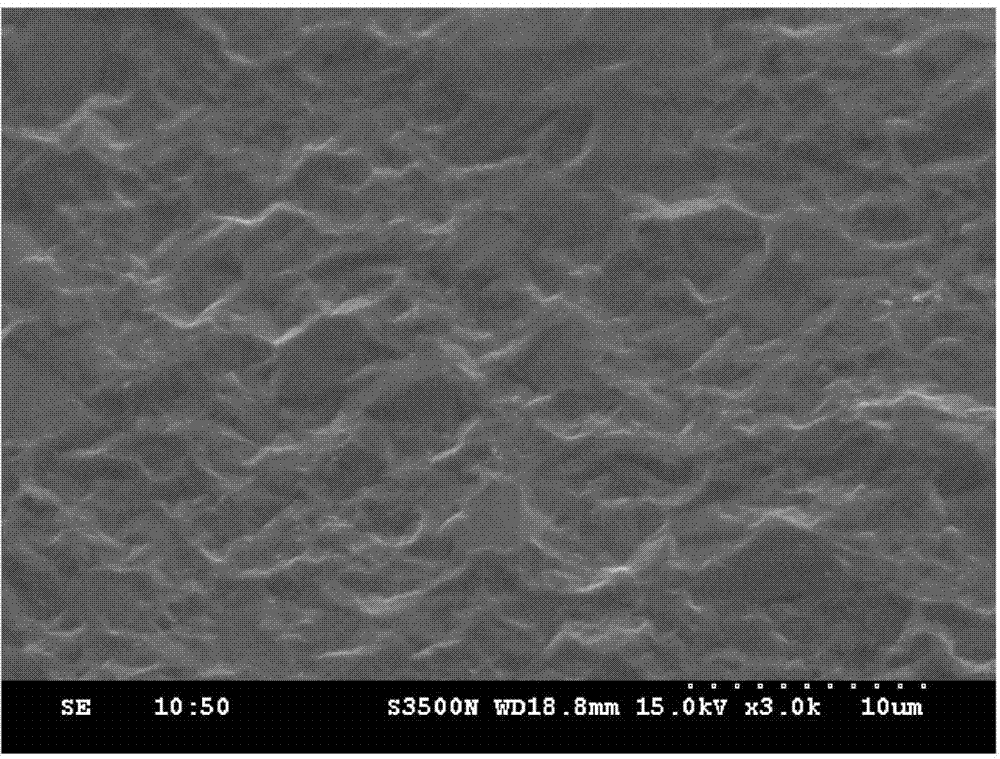

[0035] Utilize the scanning electron microscope to observe and take ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com