Preparation method of oligosaccharide containing N-acetylated structure heparin

A technology of heparin oligosaccharide and acetylation, which can be used in measurement devices, instruments, scientific instruments, etc., and can solve problems such as difficult preparation and structure determination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033]1) Dissolve 200 mg low molecular weight heparin in 2.0ml, 0.1 M, pH 7.0 sodium acetate buffer solution (containing 0.1mM calcium acetate and 100μg / ml BSA), add 50 mIU heparinase Ⅰ, and place in a 37°C water bath After 12 hours of enzymatic hydrolysis, add 50mIU heparanase I to continue enzymatic hydrolysis for 12 hours; then heat to 100°C and boil for 3 minutes to terminate the reaction, centrifuge at 10,000 rpm for 10 minutes, take the supernatant, and freeze-dry;

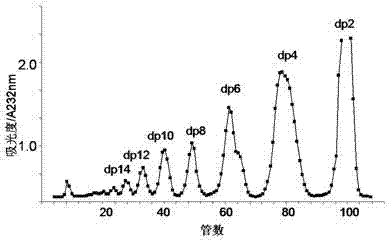

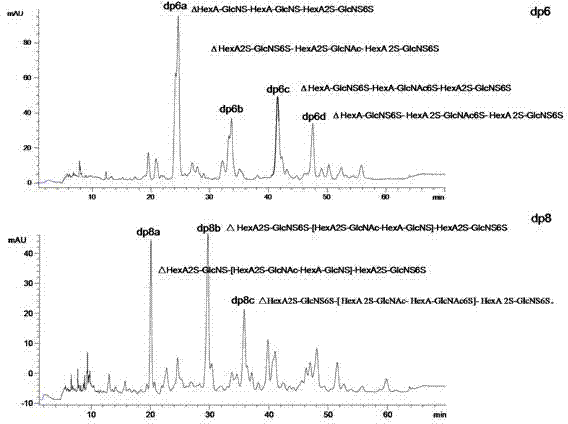

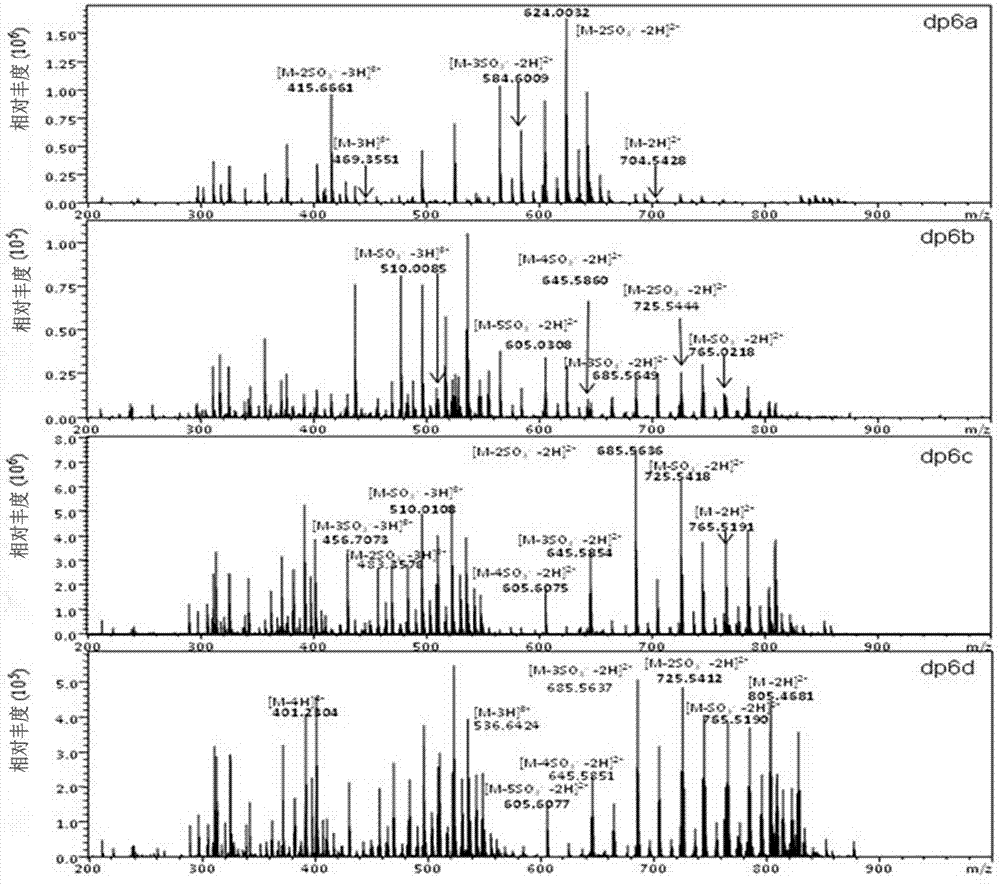

[0034] 2) Take the freeze-dried sample and dissolve it with 1ml 0.2M ammonium bicarbonate, load the sample to a series Bio-Gel chromatography column, elute with 0.2M ammonium bicarbonate, and collect it with an automatic collector at a flow rate of 0.2ml / min; the separated oligosaccharides Detect with a UV spectrophotometer at a detection wavelength of 232 nm; sequentially collect the sugar fragments corresponding to each chromatographic peak, heat at 55°C for 24h to volatilize ammonium bicarbonate, and freez...

Embodiment 2

[0048] 1) Dissolve 100 mg low molecular weight heparin in 1.0ml, 0.1 M, pH 7.0 sodium acetate buffer solution (containing 0.1mM calcium acetate and 100μg / ml BSA), add 50 mIU heparanase Ⅰ, and place in a 37°C water bath After 12 hours of enzymatic hydrolysis, add 50mIU heparanase I to continue enzymatic hydrolysis for 12 hours; then heat to 100°C and boil for 3 minutes to terminate the reaction, centrifuge at 10,000 rpm for 10 minutes, take the supernatant, and freeze-dry;

[0049] 2) Take the freeze-dried sample and dissolve it with 1ml 0.2M ammonium bicarbonate, load the sample to a series Bio-Gel chromatography column, elute with 0.2M ammonium bicarbonate, and collect it with an automatic collector at a flow rate of 0.2ml / min; the separated oligosaccharides Detect with a UV spectrophotometer at a detection wavelength of 232 nm; sequentially collect the sugar fragments corresponding to each chromatographic peak, heat at 55°C for 24h to volatilize ammonium bicarbonate, and free...

Embodiment 3

[0063] 1) Dissolve 300 mg low molecular weight heparin in 1.0ml, 0.1 M, pH 7.0 sodium acetate buffer solution (containing 0.1mM calcium acetate and 100μg / ml BSA), add 50 mIU heparanase Ⅰ, and place in a 37°C water bath After 12 hours of enzymatic hydrolysis, add 50mIU heparanase I to continue enzymatic hydrolysis for 12 hours; then heat to 100°C and boil for 3 minutes to terminate the reaction, centrifuge at 10,000 rpm for 10 minutes, take the supernatant, and freeze-dry;

[0064] 2) Take the freeze-dried sample and dissolve it with 1ml 0.2M ammonium bicarbonate, load the sample to a series Bio-Gel chromatography column, elute with 0.2M ammonium bicarbonate, and collect it with an automatic collector at a flow rate of 0.2ml / min; the separated oligosaccharides Detect with a UV spectrophotometer at a detection wavelength of 232 nm; sequentially collect the sugar fragments corresponding to each chromatographic peak, heat at 55°C for 24h to volatilize ammonium bicarbonate, and freeze...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com