Red pine nut blending oil and preparation technology

A technology of Korean pine oil and preparation process, which is applied in the fields of edible oil/fat, food science, application, etc., can solve the problems such as the inability to meet people's nutritional needs and the single oil composition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

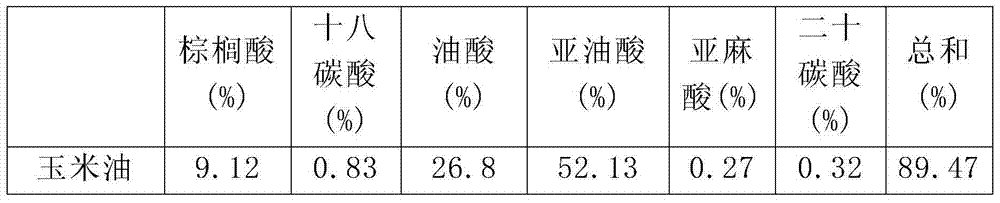

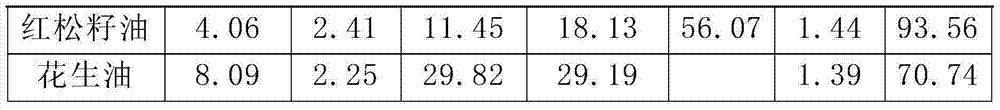

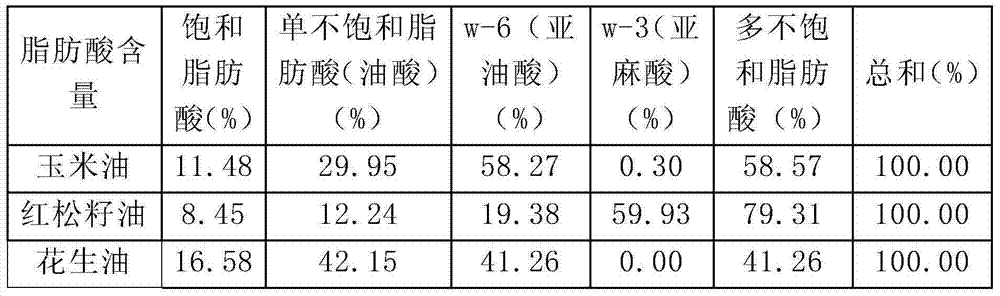

[0014] Before ingredients, according to the fatty acid content in Korean pine oil, corn oil and peanut oil, the standard determined by weight is: the content of saturated fatty acid (SFA) is 10-20 parts, and the content of monounsaturated fatty acid (MUFA) is 25-45 parts. parts, the polyunsaturated fatty acid (PUFA) content is 40-55 parts, the weight ratio of monounsaturated fatty acid (MUFA) to polyunsaturated fatty acid (PUFA) is 1:(1-1.5), omega-6 polyunsaturated fatty acid The weight ratio to ω-3 polyunsaturated fatty acid is (4.5-5.2): 1, and it is obtained through experiments: 15 parts by weight of Korean pine oil, 25 parts of corn oil, and 60 parts of peanut oil. While stirring in the mixing tank, add 0.04-0.05 part of vitamin E and 0.01-0.02 part of tert-butyl hydroquinone (TBHQ) by weight, the temperature is 40-45° C., the rotating speed is 100-150 rpm, and the stirring is 20-30 min.

Embodiment approach 2

[0016] Before ingredients, according to the fatty acid content in Korean pine oil, corn oil and peanut oil, the standard determined by weight is: the content of saturated fatty acid (SFA) is 10-20 parts, and the content of monounsaturated fatty acid (MUFA) is 25-45 parts. parts, the polyunsaturated fatty acid (PUFA) content is 40-55 parts, the weight ratio of monounsaturated fatty acid (MUFA) to polyunsaturated fatty acid (PUFA) is 1:(1-1.5), omega-6 polyunsaturated fatty acid The weight ratio to ω-3 polyunsaturated fatty acid is (4.5-5.2): 1, and it is obtained through experiments: 14 parts by weight of Korean pine oil, 12 parts of corn germ oil, and 74 parts of peanut oil. While the mixing tank is stirring, the content of vitamin E is 0.04-0.05 part by weight, the content of tert-butyl hydroquinone (TBHQ) is 0.01-0.02 part, the temperature is 40-45 ° C, the rotating speed is 100-150 rpm, and the stirring is 20 -30min.

[0017] The test method and results in the above embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com