Process for recycling acrylic wastewater

A technology for wastewater treatment and acrylic acid, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. It can solve the problems of low recovery rate of acrylic acid, dark color of acrylic acid concentrate, and many impurities , to achieve the effect of realizing industrialized production operation, reducing waste water discharge and reducing evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

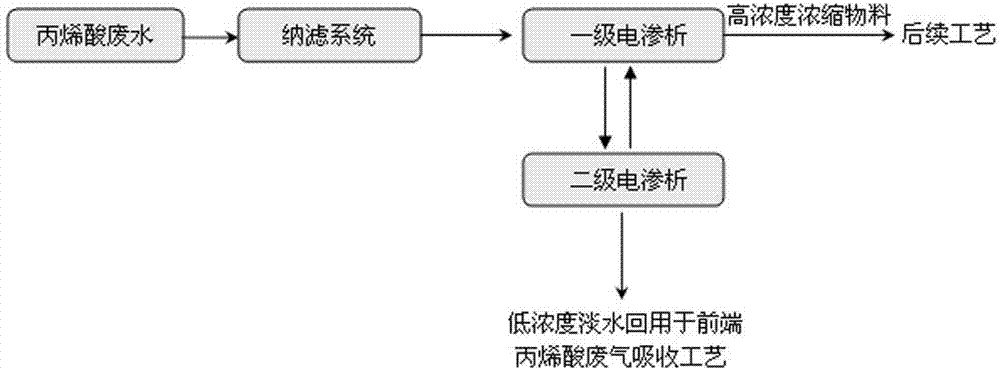

[0023] With reference to the accompanying drawings, the acrylic acid wastewater entering the process of the present invention (acrylic acid wastewater, containing impurities such as polyacrylic acid, ferric ions and pigments) is processed in the following steps:

[0024] (1) Use a nanofiltration (NF) system to remove impurities such as polyacrylic acid colloids, ferric ions, and pigments; the recovery rate of acrylic acid by nanofiltration is controlled above 98%, and polyacrylic acid colloids, The removal rate of impurities such as ferric ions and pigments can reach more than 80%. The above parameters can also be adjusted according to the needs of subsequent processing. The water produced by the nanofiltration system enters step (2) for treatment. The membrane module used in the nanofiltration system can be a coiled membrane, and the membrane material is selected from cellulose acetate (CA), sulfonated polysulfone (SPS), sulfonated polyethersulfone (SPES) and polyvinyl alcoh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com