High-nitrogen-content organic wastewater deep denitrification device and deep denitrification method

A deep denitrification and organic wastewater technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, biological water/sewage treatment, etc., can solve the problems of low denitrification efficiency, large energy consumption, complex operation, etc. Achieve the effects of improving treatment effect, simple equipment, and improving nitrogen removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

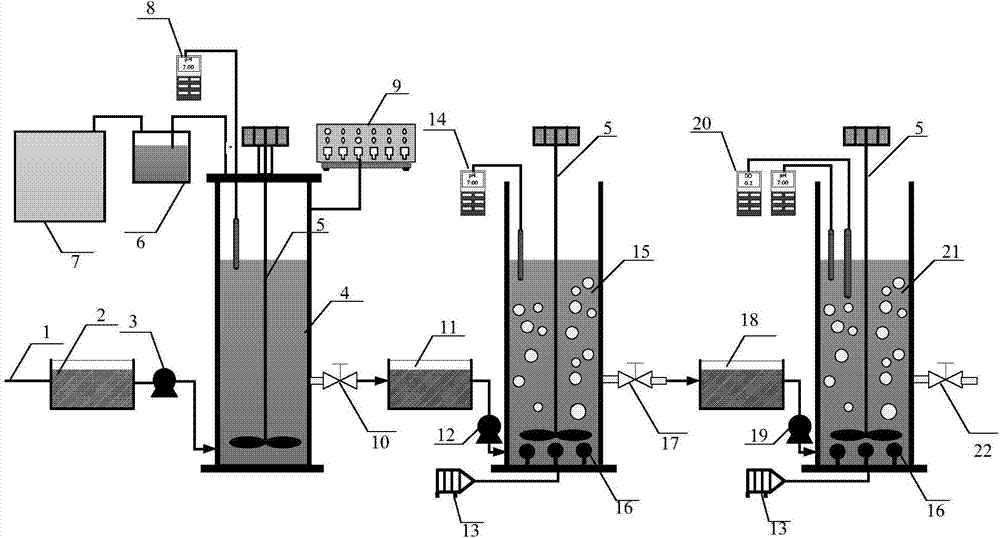

[0050] A deep denitrification device for high-nitrogen organic wastewater, the structure of which is as follows figure 1 As shown, it includes raw water regulating tank 2, anaerobic SBR reactor 4, carbon removal SBR reactor 15 and denitrification SBR reactor 21 connected in sequence, and carbon removal SBR reactor 15 is located between anaerobic SBR reactor 2 and denitrification SBR reactor 21. Between the SBR reactors 21, the anaerobic SBR reactor 2 top is connected with the air storage tank 7, and the anaerobic SBR reactor 4 water outlets are connected with the first intermediate water tank 11, the first intermediate water tank 11 and the carbon removal SBR reactor 15 The water inlet is connected, and the water outlet of carbon removal SBR reactor 15 is connected with the second intermediate water tank 18, and the second intermediate water tank 18 is connected with the water inlet of denitrification SBR reactor 21, and described anaerobic SBR reactor 4, carbon removal Both t...

Embodiment 2

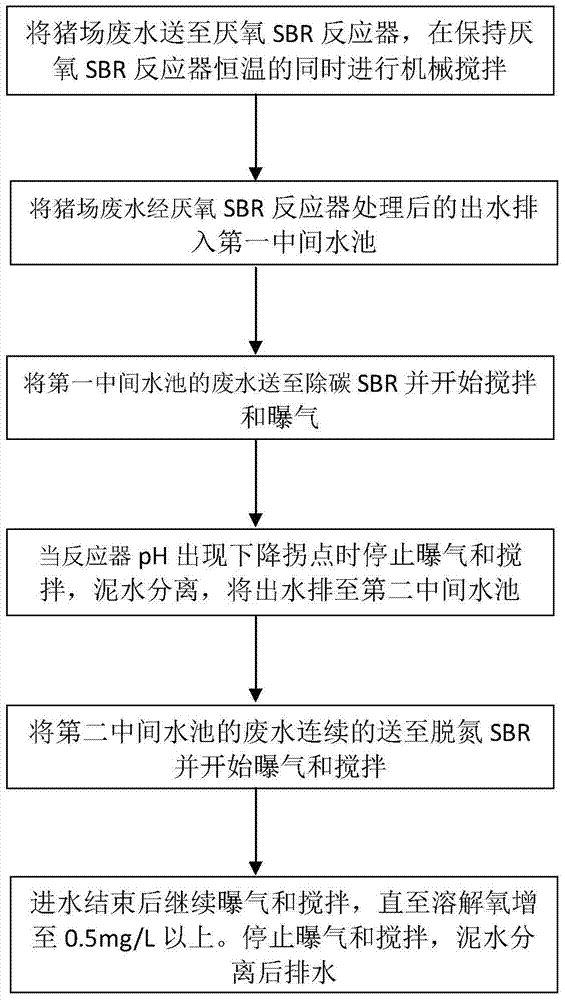

[0055] A method for deep denitrification of high-nitrogen organic wastewater, comprising the following steps:

[0056] 1) Add anaerobic activated sludge to high nitrogen-containing organic wastewater, so that the concentration of anaerobic activated sludge reaches 10000mg / L, and the temperature of wastewater treatment is 32°C. When the pH of wastewater drops, the mud and water will be separated for preliminary treatment waste water;

[0057] 2) Add activated sludge to the preliminary treatment wastewater obtained in step 1) to make the concentration of activated sludge reach 4000mg / L, start the carbon removal treatment by aeration, the temperature of the carbon removal treatment wastewater is 20°C, and the dissolved oxygen is 2.5 mg / L, when the wastewater pH changes from increasing to decreasing, the aeration is stopped, the carbon removal treatment is completed, the mud and water are separated, and the wastewater after carbon removal is obtained;

[0058] 3) Add mixed sludge...

Embodiment 3

[0060] Utilize the denitrification device described in embodiment 1 to carry out the method for deep denitrification, the steps are as follows:

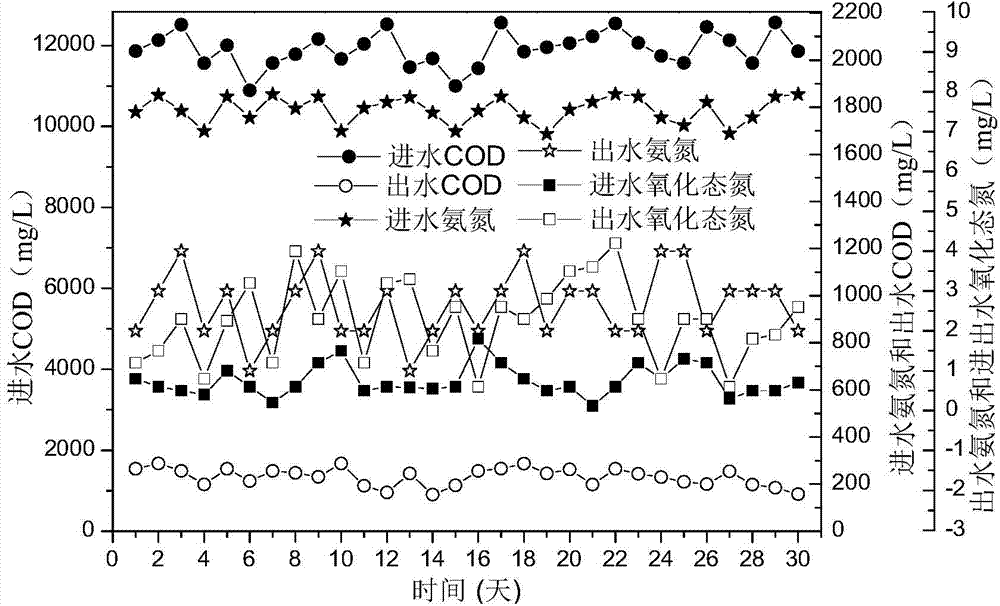

[0061] (1) Input high-nitrogen organic wastewater into the anaerobic SBR reactor through the anaerobic SBR inlet pump, and add anaerobic activated sludge to the anaerobic SBR reactor to make the anaerobic activated sludge concentration reach 10050mg / L, anaerobic The drainage ratio of the oxygen SBR reactor is 30%. The temperature of the anaerobic SBR reactor is maintained at 32°C by the temperature control device. The stirrer is turned on for mechanical stirring, and the stirring speed reaches 50rpm. Processes such as methane degrade organic matter in wastewater and generate gas. The generated gas enters the gas storage tank after being filtered. The pH of anaerobic SBR will increase during the process of methane production. When the pH drops, the agitator is turned off. After the mud water is separated, it is discharged into the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com