A compound fertilizer active additive containing sulfur-based silicon powder

An active additive, sulfur-based silica fume technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve problems such as difficulties in the activity and reproduction of beneficial microorganisms, decline in vegetative growth and grain yield, and nutrient loss, so as to increase water storage and storage. Fertilizer and air permeability, effects of increasing vegetative growth and grain yield, changing compaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

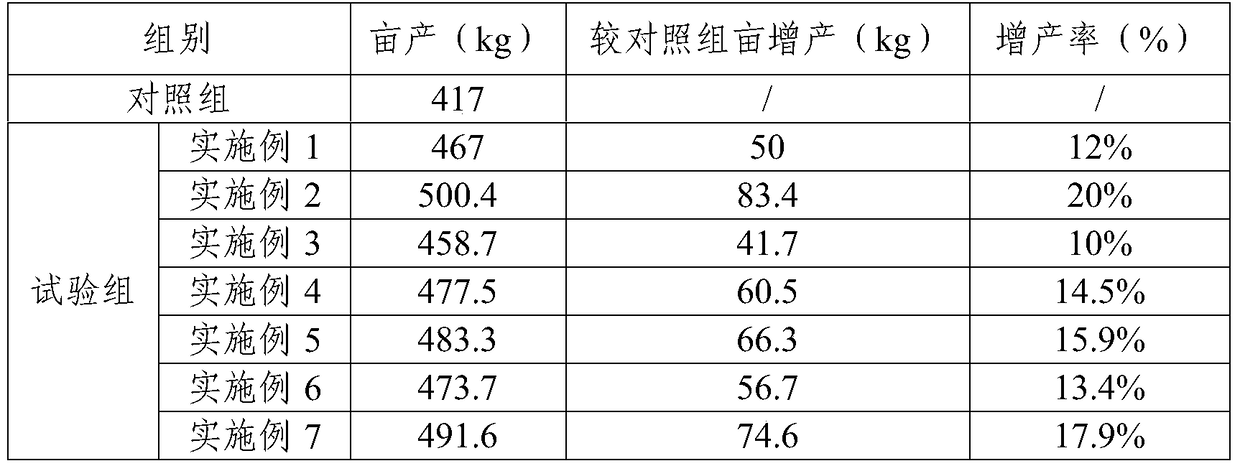

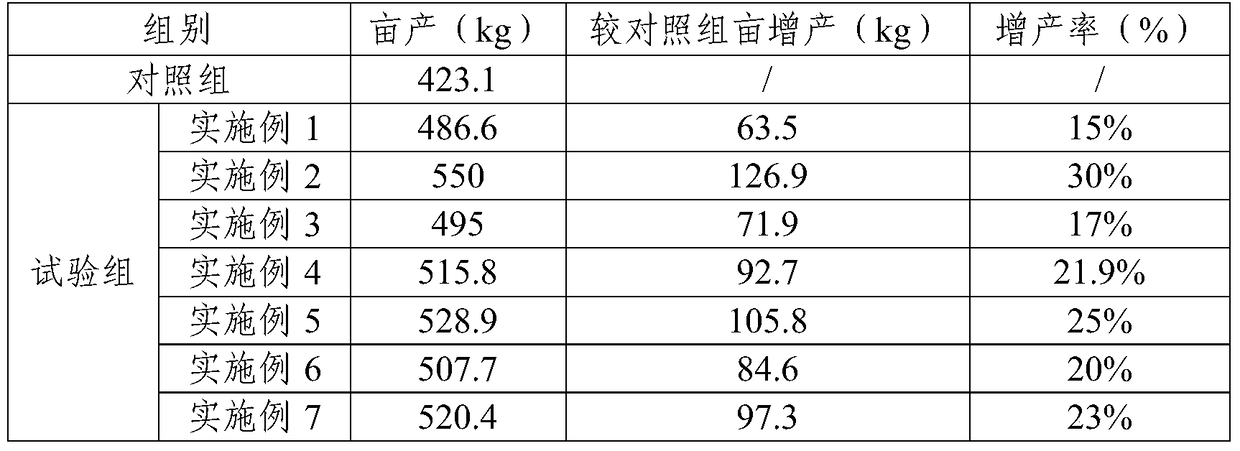

Examples

Embodiment 1

[0016] The active additive for compound fertilizer containing sulfur-based silicon powder of the present embodiment is made of the following raw materials in mass percentage: 50% of weathered coal, 35% of sulfur-based silicon powder, 14.9% of biological fertilizer, and 0.1% of plant growth regulator; The plant growth regulator is gibberellin; the sulfur-based silicon powder is made by mixing the following raw materials in mass percentage: potassium sulfate 80%, sodium silicate 18%, and compound amino acid powder 2%; the biological bacterial fertilizer is made of the following The raw materials of mass percentage are mixed and made: excrement fermented product 99.5%, microbial bacterial classification 0.5%, described microbial bacterial classification is JT bacterial classification (purchased from Xi'an Zhongsheng Chemical Co., Ltd.), and described excrement fermented product is accumulated and fermented by animal excrement Made in 20 days.

[0017] The preparation method of th...

Embodiment 2

[0019] The active additive for compound fertilizer containing sulfur-based silicon powder of the present embodiment is made of the following raw materials in mass percentage: 55% of weathered coal, 32.5% of sulfur-based silicon powder, 12.3% of biological bacterial fertilizer, and 0.2% of plant growth regulator; The plant growth regulator is gibberellin; the sulfur-based silicon powder is made by mixing the following raw materials in mass percentage: potassium sulfate 75%, sodium silicate 23.5%, and compound amino acid powder 1.5%; the biological bacterial fertilizer is composed of the following The raw materials of mass percentage are mixed and made: excrement fermented product 99.2%, microbial bacterial classification 0.8%, described microbial bacterial classification is JT strain II type (purchased from Xi'an Zhongsheng Chemical Co., Ltd.), and described excrement fermented product is made of animal excrement It is made by accumulating and fermenting for 25 days.

[0020] T...

Embodiment 3

[0022] The active additive for compound fertilizer containing sulfur-based silicon powder of the present embodiment is made of the following raw materials in mass percentage: 60% of weathered coal, 30% of sulfur-based silicon powder, 9.8% of biological fertilizer, and 0.2% of plant growth regulator; The plant growth regulator is gibberellin; the sulfur-based silicon powder is made by mixing the following raw materials in mass percentage: potassium sulfate 70%, sodium silicate 29%, and compound amino acid powder 1%; the biological bacterial fertilizer is made of the following The raw materials of mass percentage are mixed and made: excrement fermented product 99.0%, microbial strain 1.0%, described microbial strain is JT strain II type (purchased from Xi'an Zhongsheng Chemical Co., Ltd.), and described feces fermented product is made of animal excrement It is made by stacking and fermenting for 30 days.

[0023] The preparation method of the compound fertilizer active additive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com