Diacerein crystal and preparation method thereof

A diacerein and crystal technology, applied in the field of diacerein crystals, can solve the problems of unsatisfactory purification effect, low yield, cumbersome purification process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

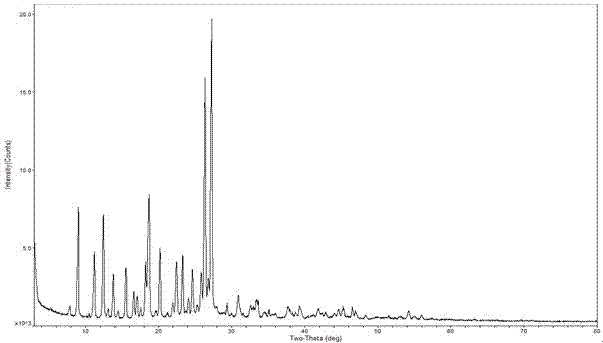

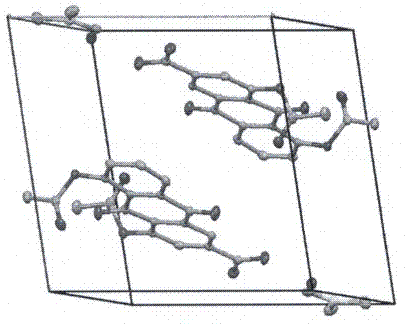

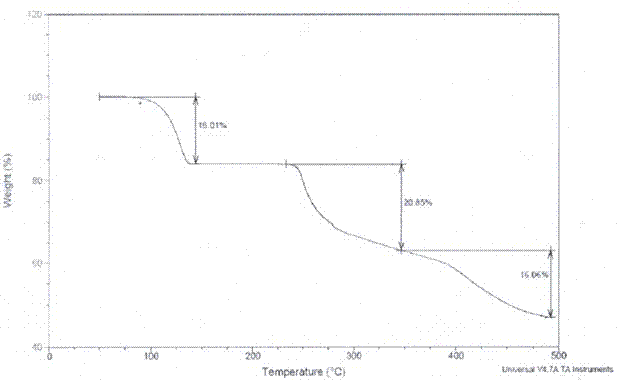

[0050] Mix 25ml of dimethylformamide and 80ml of acetone to obtain a mixed solvent, weigh 0.5g of diacerein and add it to the mixed solvent, heat and stir in a water bath at 65°C to dissolve, filter to remove insoluble matter, stand at 25°C for 6 hours, and a yellow color is precipitated The crystalline powder was suction filtered and dried to obtain 0.52 g of diacerein crystals. The resulting crystals have X-ray powder diffraction pattern data as shown below:

[0051]

Embodiment 2

[0053] Mix 37ml of dimethylformamide and 90ml of dichloromethane to obtain a mixed solvent, weigh 0.5g of diacerein and add it to the mixed solvent, heat and stir in a water bath at 50°C to dissolve, filter to remove insoluble matter, and stand at 30°C for 6.5 hours. A yellow crystalline powder was precipitated, filtered with suction, and dried to obtain 0.515 g of diacerein crystals. The X-ray powder diffraction spectrum data of the obtained crystal are the same as in Example 1.

Embodiment 3

[0055] Mix 30ml of dimethylformamide and 90ml of methanol to obtain a mixed solvent, weigh 1.0g of diacerein and add it to the mixed solvent, heat and stir in a water bath at 65°C to dissolve, filter to remove insoluble matter, and stand at 10°C for 8 hours, and a yellow color is precipitated The crystalline powder was suction filtered and dried to obtain 1.025 g of diacerein crystals. The X-ray powder diffraction spectrum data of the obtained crystal are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com