Bio-based polyethylene glycol terephthalate and preparation method thereof

A technology of ethylene glycol phthalate and purified terephthalic acid, which is applied in the field of bio-based polyethylene terephthalate and its preparation, can solve problems restricting the development of the polyester industry and achieve low-cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

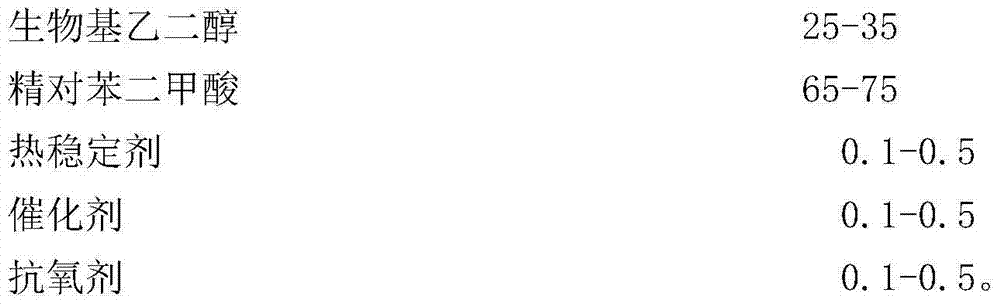

Method used

Image

Examples

Embodiment 1

[0026] The preparation of bio-based polyethylene terephthalate comprises the following steps:

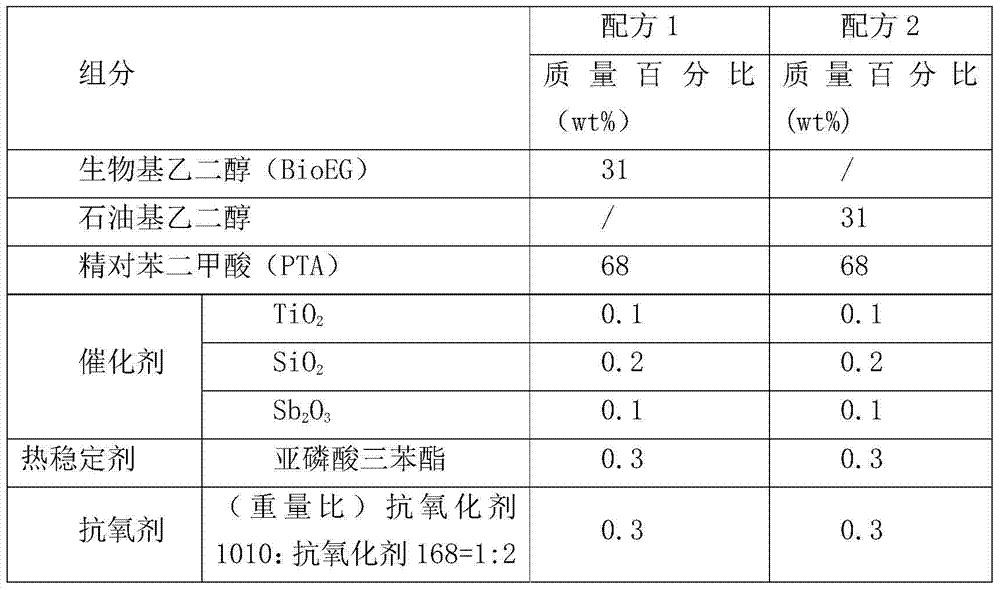

[0027] (1) prepare materials by formula 1 of table 1;

[0028] (2) First mix PTA and BioEG evenly, then add to the polymerization kettle, add TiO 2 , SiO 2 and Sb 2 o 3 As a catalyst; add triphenyl phosphite as a stabilizer, add antioxidant 1010 and antioxidant 168 as an antioxidant for esterification, wherein the weight ratio of antioxidant 1010 and antioxidant is 1:2. The esterification reaction was carried out at a temperature of 240° C., a pressure of 0.3 MPa, and an esterification time of 4 hours. After the esterification is completed, vacuum polycondensation is carried out, and the polycondensation reaction is carried out at a temperature of 270° C., and the reaction time is 5.5 hours; after the polycondensation is completed, bio-based polyethylene terephthalate (PET) can be obtained.

[0029] Prepare petroleum-based polyethylene terephthalate, comprising the steps:

[0...

Embodiment 2

[0035] The bio-based polyethylene terephthalate prepared by Example 1 formula 1, and the petroleum-based polyethylene terephthalate prepared by formula 2 are tested as shown in table 2, and the test results are also shown in the table 2 shows:

[0036] Table 2 The test results of polyethylene terephthalate

[0037]

[0038] The above test results show that: the bio-based polyethylene terephthalate prepared by the present invention is different from the petroleum-based polyethylene terephthalate prepared under the same conditions and the same amount in terms of tensile strength, elongation at break, Flexural strength, flexural modulus, notched Izod impact strength, heat distortion temperature, density, intrinsic viscosity, and melting point are all equivalent, and some properties are even better than petroleum-based polyethylene terephthalate.

[0039] However, the bio-based polyethylene terephthalate prepared by the present invention has lower cost and is more environmenta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com