A kind of refrigerator sealing strip material and preparation method thereof

A technology for sealing strips and refrigerators, applied in the field of thermoplastic elastomer materials, which can solve the problems of difficult to obtain sealing materials for refrigerators, poor solvent resistance, poor oil resistance, small permanent deformation, etc., achieve good resilience, improve oil resistance and resistance Solvent property, effect of lowering interfacial tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

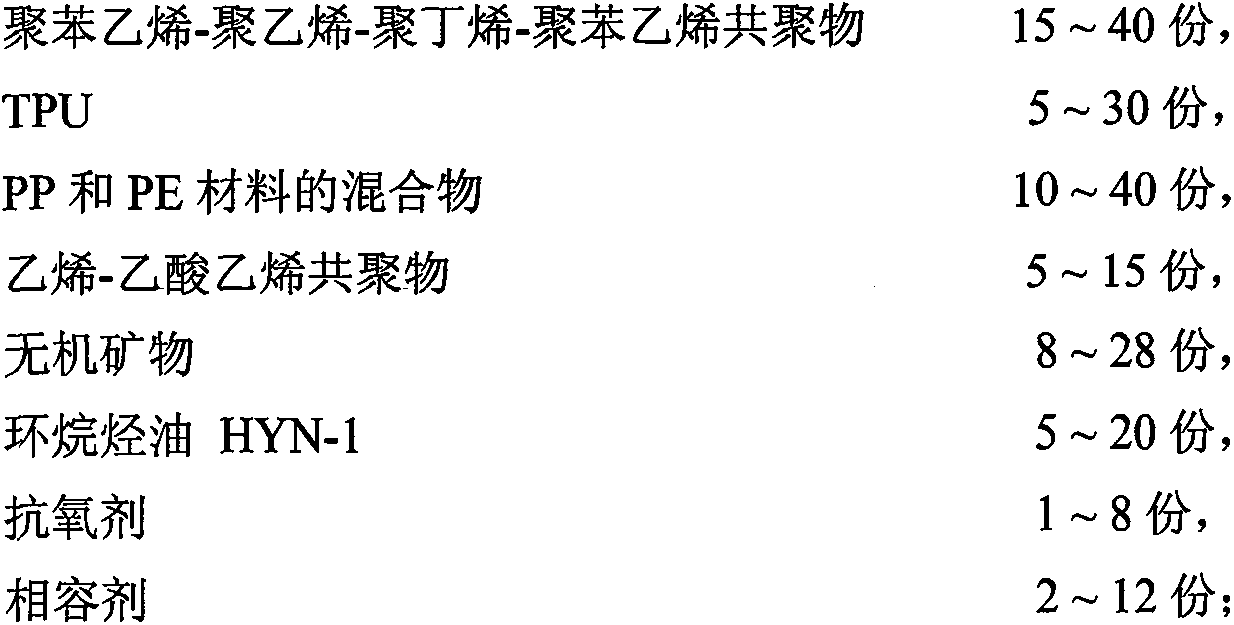

[0034] The refrigerator sealing strip material of the present embodiment comprises the following components by weight:

[0035]

[0036]

[0037] Wherein, the weight ratio of PP to PE in the mixture of PP and PE materials is 0.7:1.

[0038] The preparation method of the above-mentioned refrigerator sealing strip material comprises the following steps:

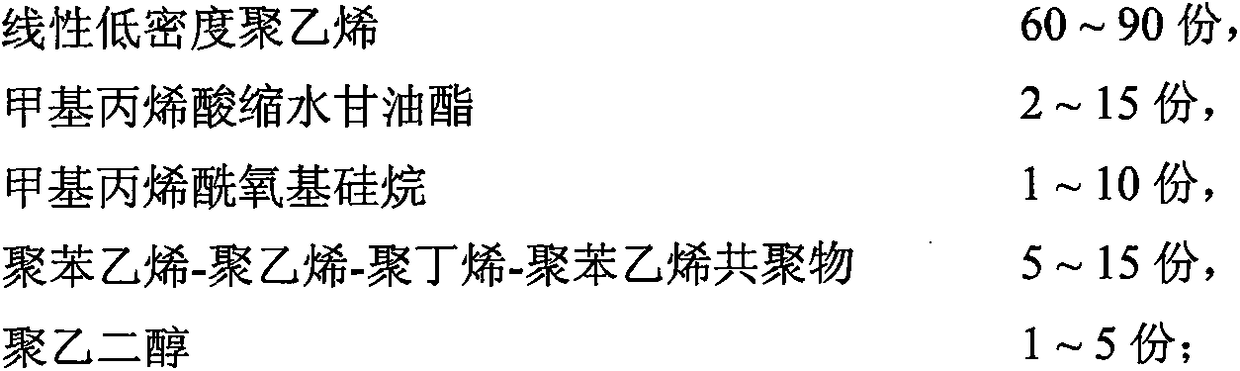

[0039] (1) Preparation of compatibilizer

[0040]Carry out electron beam pre-irradiation to 60g linear low density polyethylene, the irradiation dose is 10kGy, and the irradiation time is 8min;

[0041] Sprinkle 2g of methacryloxysilane evenly on the surface of the linear low density polyethylene after pre-irradiation, and stir in a mixer at a speed of 1000r / min for 10min to obtain a mixture A;

[0042] Add 2g glycidyl methacrylate, 8g polystyrene-polyethylene-polybutylene-polystyrene copolymer and 5g polyethylene glycol to mixture A, and stir for 20min at a speed of 1000r / min in the mixer , to obtain mixture B; in thi...

Embodiment 2

[0049] The refrigerator sealing strip material of the present embodiment comprises the following components by weight:

[0050]

[0051] Wherein, the weight ratio of PP to PE in the mixture of PP and PE materials is 0.9:1.

[0052] The preparation method of the above-mentioned refrigerator sealing strip material comprises the following steps:

[0053] (1) Preparation of compatibilizer

[0054] Carry out electron beam pre-irradiation to 70g linear low density polyethylene, the irradiation dose is 20kGy, and the irradiation time is 7min;

[0055] Sprinkle 6g of methacryloxysilane evenly on the surface of the linear low density polyethylene after pre-irradiation, and stir for 7min at a speed of 2000r / min in a mixer to obtain a mixture A;

[0056] Add 5g glycidyl methacrylate, 15g polystyrene-polyethylene-polybutylene-polystyrene copolymer and 2g polyethylene glycol to mixture A, and stir for 18min at a speed of 2000r / min in the mixer , to obtain mixture B; in this step, the...

Embodiment 3

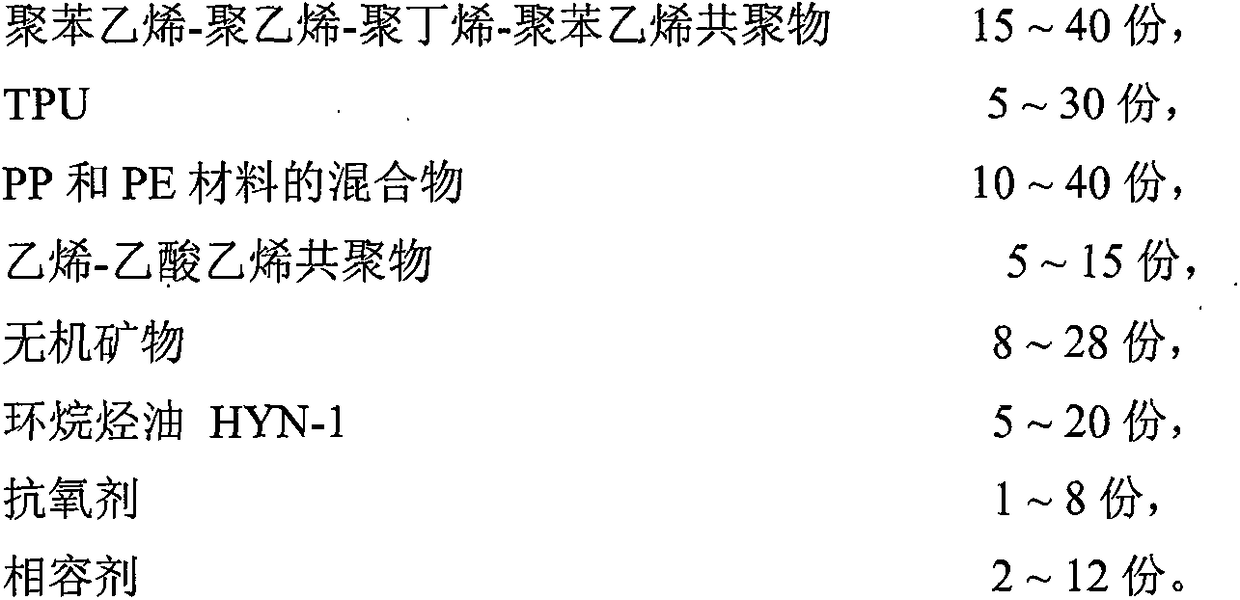

[0063] The refrigerator sealing strip material of the present embodiment comprises the following components by weight:

[0064]

[0065] Wherein, the weight ratio of neutral alumina to nano titanium dioxide is 1:2; the weight ratio of PP to PE in the mixture of PP and PE materials is 2.3:1.

[0066] The preparation method of the above-mentioned refrigerator sealing strip material comprises the following steps:

[0067] (1) Preparation of compatibilizer

[0068] Carry out electron beam pre-irradiation to 80g linear low density polyethylene, the irradiation dose is 30kGy, and the irradiation time is 6min;

[0069] Sprinkle 1g of methacryloxysilane evenly on the surface of the linear low density polyethylene after pre-irradiation, and stir in a mixer at a speed of 3000r / min for 5min to obtain mixture A;

[0070] Add 8g glycidyl methacrylate, 10g polystyrene-polyethylene-polybutylene-polystyrene copolymer and 4g polyethylene glycol to mixture A, and stir for 15min at a speed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com