Magnetic palladium composite catalyst, and preparation method and use thereof

A composite catalyst and magnetic technology, applied in organic chemistry methods, carbon-based compound preparation, chemical instruments and methods, etc., can solve the problems of low catalytic performance and recycling efficiency of materials, and achieve the effect of improving separation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

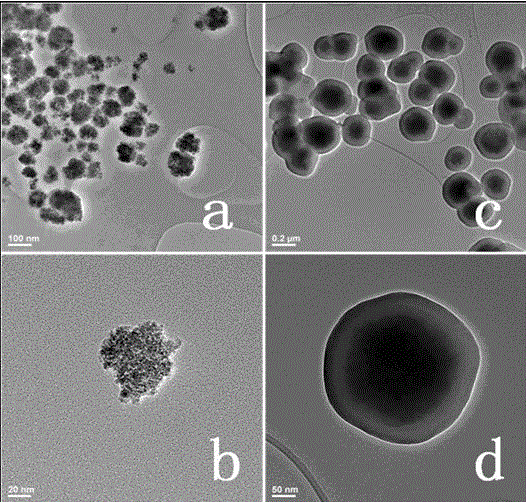

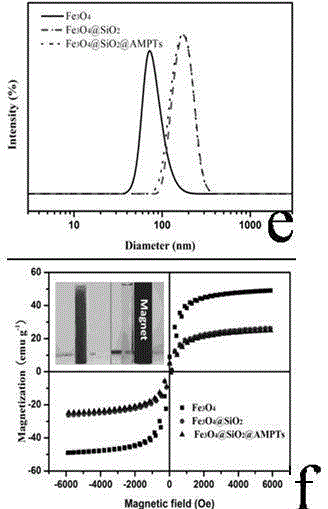

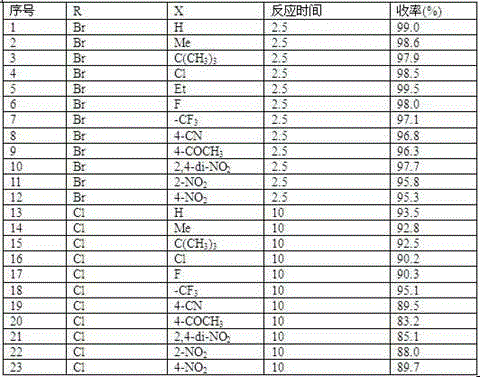

[0021] Provide a kind of magnetic palladium composite catalyst, described magnetic palladium composite catalyst is based on superparamagnetic Fe 3 o 4 SiO 2 nanospheres as a carrier, the Fe 3 o 4 SiO 2 The surface of nano microspheres is covalently modified to support amino Pd (II) particles, and the structural formula of the magnetic palladium composite catalyst is:

[0022] .

[0023] see figure 1 , provide a kind of preparation method of magnetic palladium composite catalyst, comprising the steps of:

[0024] (1) Nano Fe 3 o 4The preparation process

[0025] Under nitrogen protection, 2.5 g of ferrous chloride hydrate, 3.2 g of ferric chloride and 100 mL of deionized water were added to a 250 mL four-necked flask. Heat the reaction solution to 40 °C, add 10 g of ammonia water dropwise, keep stirring at this temperature for 30 minutes, raise the temperature to 80 °C, add 8.8 g of sodium citrate aqueous solution (dissolved in 50 mL of deionized water) and stir for...

Embodiment 2

[0033] The difference between this embodiment and specific example 1 is that the alkali used in step (1) is sodium hydroxide, potassium hydroxide, ammonia water and sodium ethoxide. Other steps and implementation methods are the same as the specific examples.

Embodiment 3

[0035] The difference between this embodiment and the specific example 1 or 2 is that the reaction temperature used in step (1) is 80-120°C. Other steps and implementation methods are the same as the specific examples.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com