Offline embossed cigarette paper making method and offline embossed cigarette paper

A manufacturing method and technology for cigarette paper, which are applied in the directions of reproduction/marking method, printing, printing device, etc., can solve the problems of large investment in printing plate equipment, high cost, printing failure, etc., so as to reduce production and equipment costs and improve production effect. , to eliminate the effect of homogenization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

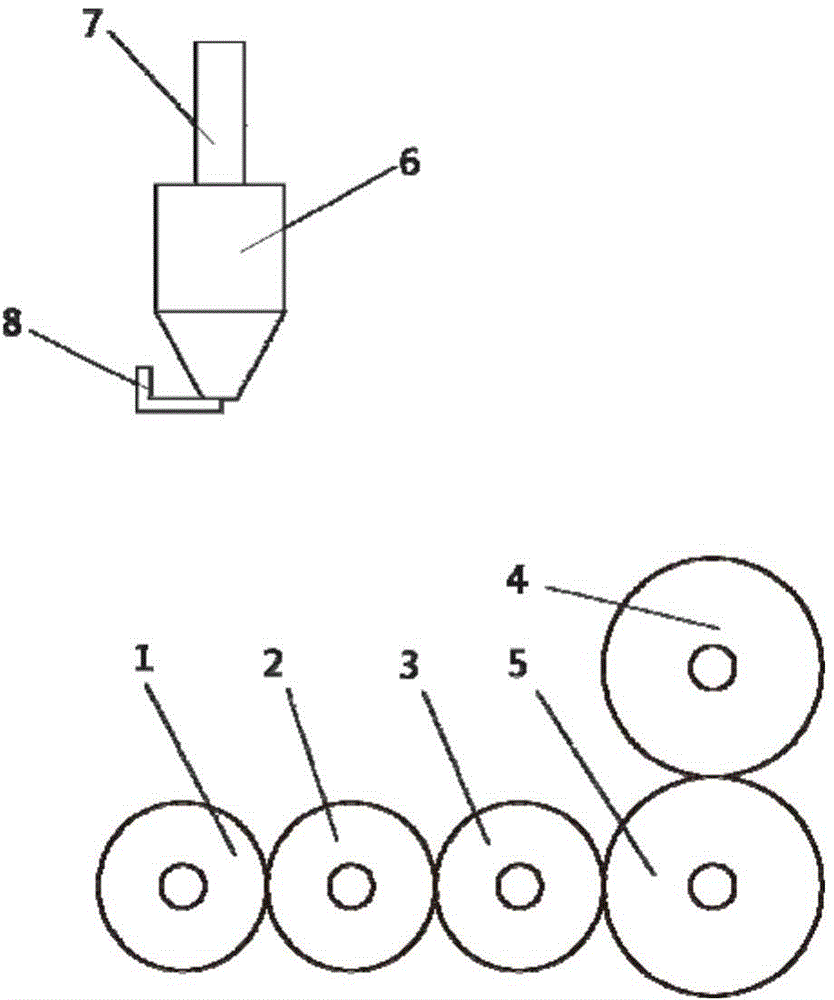

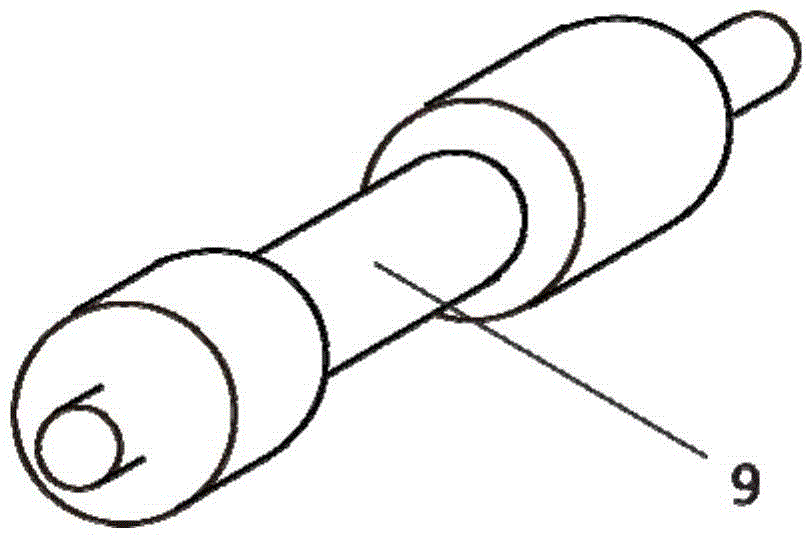

[0026] An off-line embossed cigarette paper, the cigarette paper uses tobacco paste with low moisture content as printing material, transfers the smoke paste to the specific pattern protrusions of the relief printing plate through the printing material transfer system, and then embosses it on the cigarette paper above, to obtain cigarette paper with concave-convex lines and a pattern consistent with the lines; the printing material transfer system includes a printing material unloading device, a feed rubber roller 1, a transfer rubber roller 2, a transfer rubber roller 3, and cooperating Embossing rubber roller 4 and embossing plate 5; the unloading device includes a funnel-shaped storage device 6, an extruding device 7 and a material inlet regulator 8, the printing raw material is contained in the storage device 6, and the extruding device 7 presses down , so that the printing material falls from the feed port, the feed port regulator 8 can control the opening and closing size...

Embodiment 2

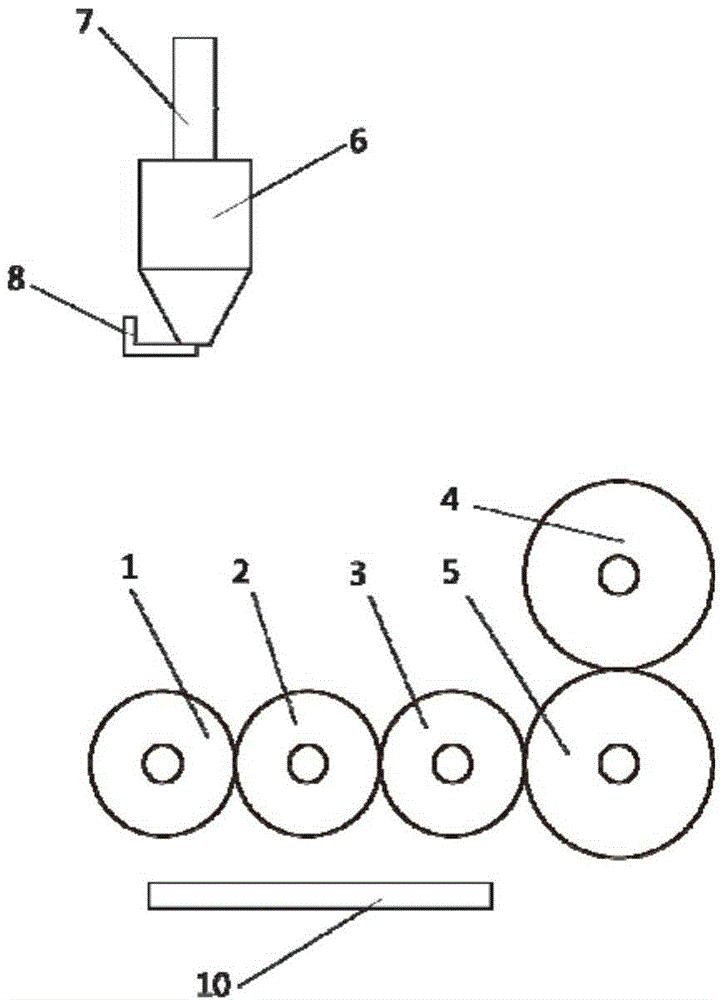

[0032]An off-line embossed cigarette paper, which uses tobacco paste with high moisture content as the printing material, transfers the tobacco paste to the specific pattern protrusions of the relief printing plate through the printing material transfer system, and then embosses it on the cigarette paper On the above, a cigarette paper with a concave-convex pattern and a color that matches the pattern is obtained; the printing material transfer system is basically the same as that described in Example 1, the difference is that in order to improve the transmission system for the transferred printing material Scope of application, reduce the cost of adaptive processing of printing raw materials, install a drying device 10 at the position between the printing raw material from the unloading device to the relief printing plate 5, and set the raw material during the transfer process according to the parameters such as the moisture content of the raw material required for cigarette pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com