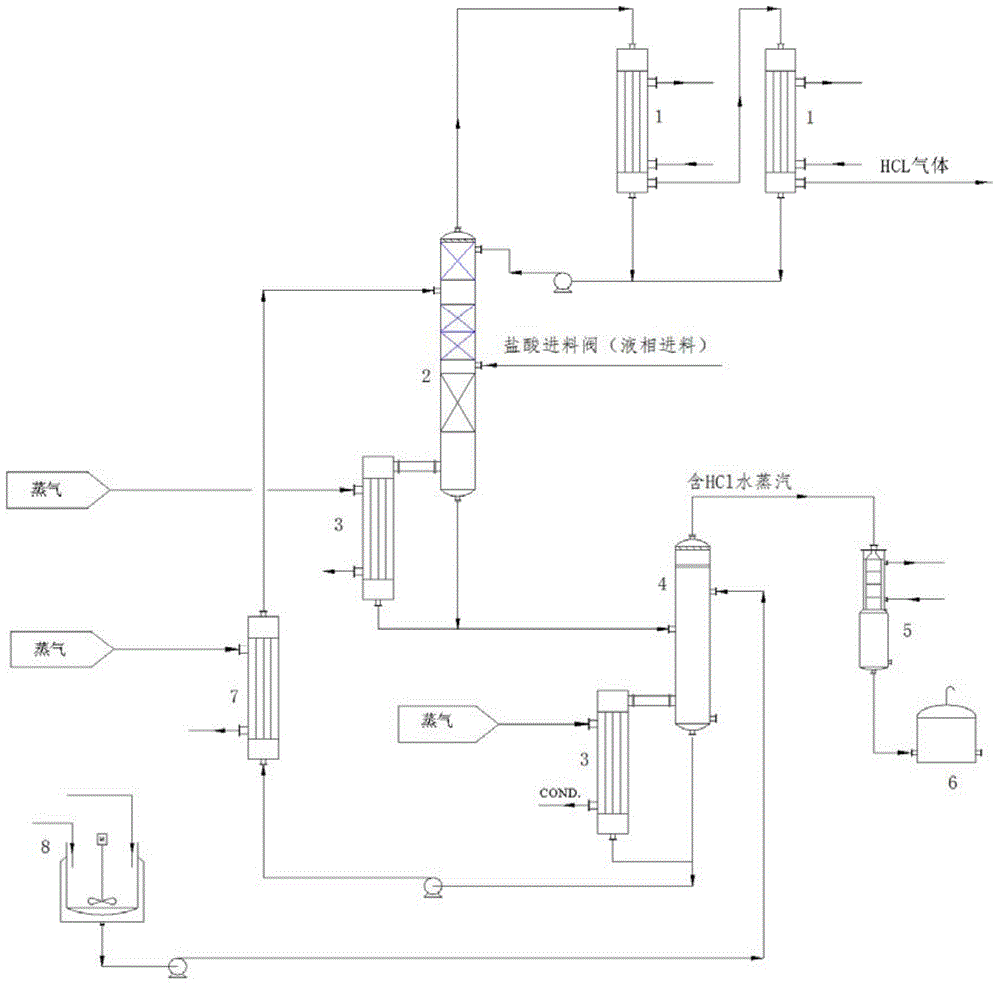

Technology for deeply resolving by-product hydrochloric acid to prepare hydrogen chloride

A technology of by-product hydrochloric acid and in-depth analysis, applied in chlorine/hydrogen chloride, chloride preparation and other directions, can solve problems such as calcium chloride pollution and failure, and achieve the effect of reducing the cost of three waste treatment, improving the use efficiency, and prolonging the cycle time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Pass the by-product hydrochloric acid containing high boiling point compounds, salts and solid impurities with a percentage concentration of 22% into the vaporization tower. After heating and vaporizing with steam at 120°C and a pressure of 1.0Mpa, the by-product hydrochloric acid is injected in the vapor phase. The valve enters the desorption tower, while the high boiling point compounds, salts and solid impurities in the by-product hydrochloric acid are discharged through the bottom of the vaporization tower for wastewater treatment; Deep analysis to produce hydrogen chloride, after adopting the process of the present invention, the calcium chloride solution circulates for more than 168 hours without replacement, and the recovery rate of by-product hydrochloric acid reaches 96.75%.

Embodiment 2

[0014] Pass the by-product hydrochloric acid containing high boiling point compounds, salts and solid impurities with a percentage concentration of 31% into the vaporization tower. After heating and vaporizing with steam at 120°C and a pressure of 1.0Mpa, the by-product hydrochloric acid is injected in the vapor phase. The valve enters the desorption tower, while the high boiling point compounds, salts and solid impurities in the by-product hydrochloric acid are discharged through the bottom of the vaporization tower for wastewater treatment; Deep analysis to produce hydrogen chloride, after adopting the process of the present invention, the calcium chloride solution circulates for more than 168 hours without replacement, and the recovery rate of by-product hydrochloric acid exceeds 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com