New method and apparatus of membrane-method calcium chloride mother liquid concentration

A technology of calcium chloride and a new method, applied in the field of concentration of industrial calcium chloride mother liquor, can solve the problems of high processing cost, affect membrane performance, poor economy, etc., and achieve the effects of reducing membrane pollution, prolonging operation period and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

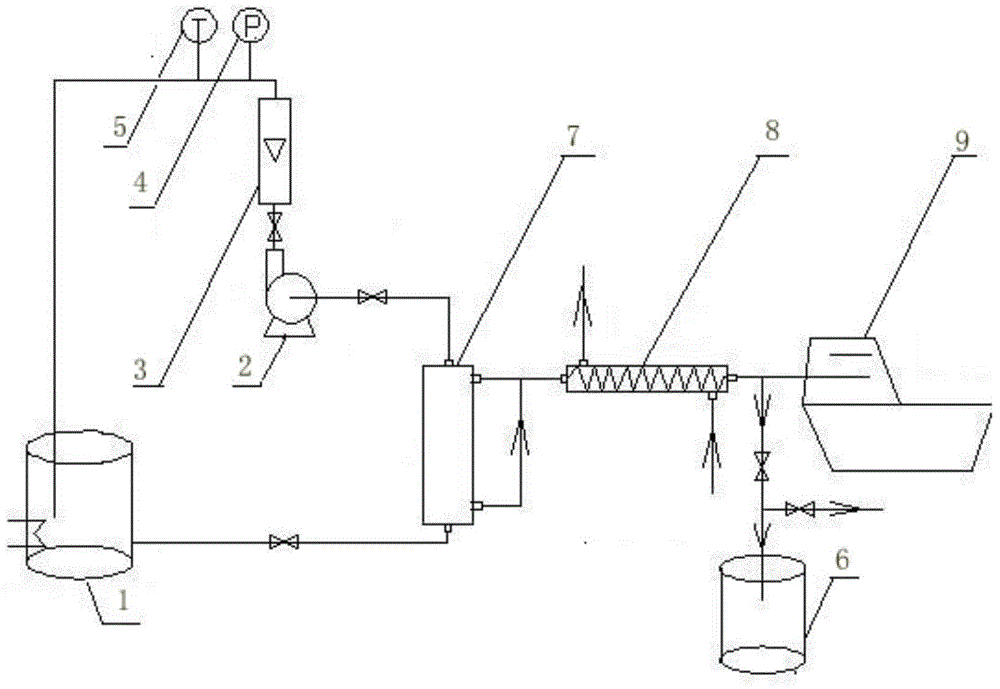

[0043] (1) As shown in Figure 1, add polycarboxylic acid-type chelating agent R to the mother liquor, adjust the pH of the calcium chloride mother liquor to 6.5, heat the liquid to be treated at a temperature of 65°C, and wait until the preset temperature is stable for about 10 minutes, then turn on The circulation pump realizes the circulation of the feed liquid between the membrane module and the liquid storage tank, records the feed flow rate through the flow meter, records the temperature with the thermometer, records the delivery pressure with the pressure gauge, and turns on the circulating water of the condenser;

[0044] (2) Turn on the vacuum pump and record the vacuum pressure, at which point the membrane distillation process officially begins. Part of the feed liquid evaporates into gas, passes through the micropores of the hydrophobic membrane, is drawn into the condenser by the vacuum pump, and is collected after cooling, and the other part of the feed liquid is ci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com