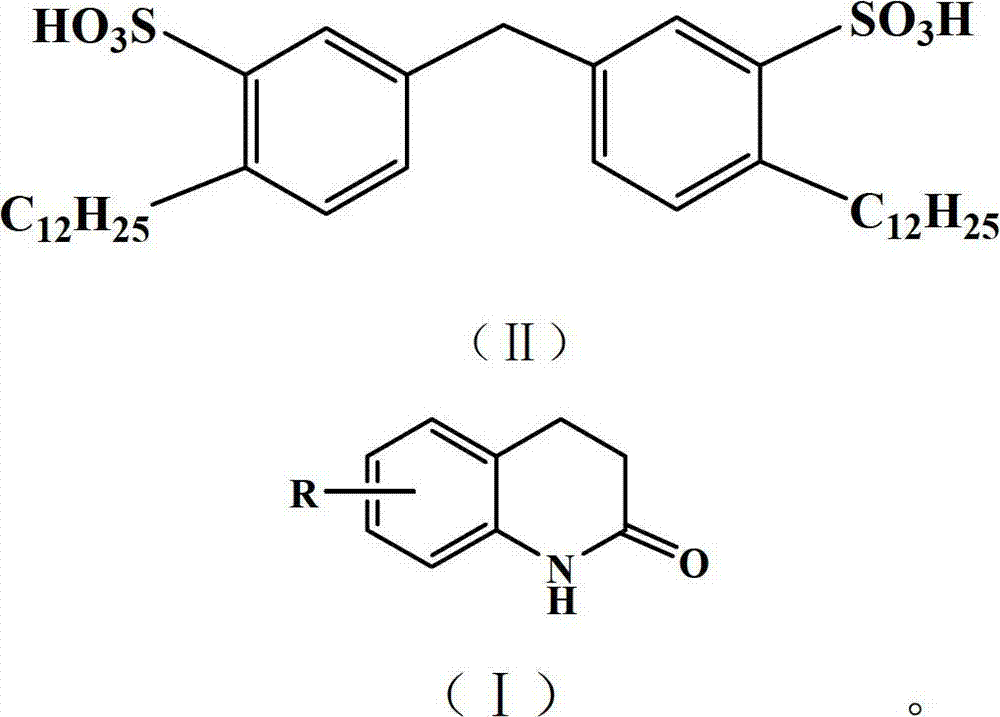

Synthetic method of hydroxy-substituted-3,4-dihydro-2(1H)-quinolinone compound

A technology of quinolinones and synthesis methods, applied in the direction of organic chemistry, etc., can solve the problems of complex post-treatment process and environmental impact, and achieve the effect of simple synthesis method, low cost, and cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

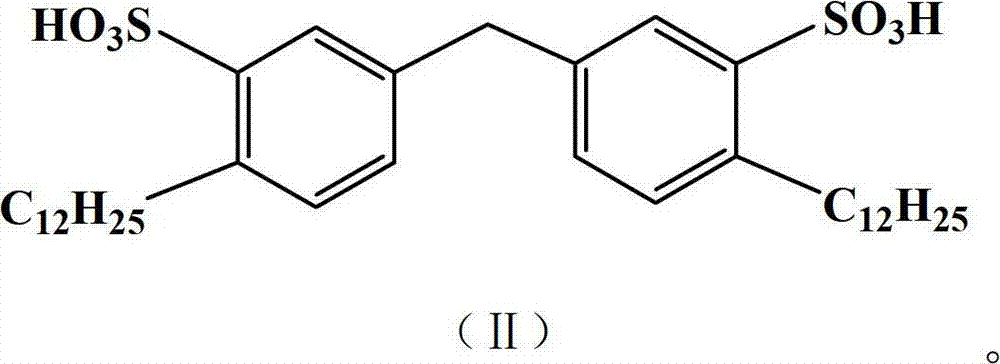

[0021] The preparation of embodiment 1 gemini surface active agent

[0022] 1) Alkylation Add 16.8g (0.1mol) of diphenylmethane, anhydrous AlCl 3 13g, fully stirred to disperse the catalyst evenly, at 45-50°C, add 34g (0.2mol) of dodecene dropwise, the dropping time is controlled at 20-30min to complete the dropwise addition, then gradually raise the reaction temperature to 70°C, and keep No change, react for 8 hours, after the reaction, adjust the reaction solution to neutral, extract with toluene, dry over anhydrous magnesium sulfate, filter, concentrate to obtain the alkylated product for the next step of sulfonation;

[0023] 2) Sulfonation In a four-necked reaction flask equipped with an electric stirrer, a thermometer, a reflux condenser, and a dropping funnel, add the alkylated product obtained above, and add 24 g (0.2 mol) of chlorosulfonic acid dropwise under vigorous stirring. ), the dropping time is 1h, the reaction temperature is controlled at 20-25°C, and the rea...

Embodiment 2

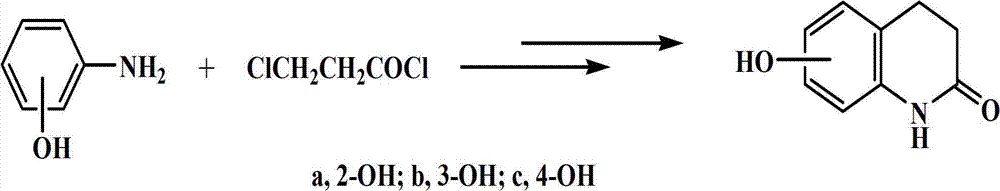

[0025] Example 2 Preparation of 6-hydroxy-3,4-dihydro-2(1H)-quinolinone

[0026] In a 150mL three-neck flask, add 10.9g (0.1mol) of p-hydroxyaniline, 109g of the gemini surfactant prepared by the method in Example 1, and 12.7g (0.1mol) of propionyl chloride, and stir and react at 110°C for 10 hours. The reaction solution was cooled to room temperature (25°C), and then extracted three times with 20 mL of toluene. The extract was concentrated under reduced pressure until no solvent flowed out. The concentrate was recrystallized with industrial methanol and dried to obtain 14.2 g of white solid, namely 6-hydroxy-3, 4-Dihydro-2(1H)-quinolinone, yield 87%, m.p.235~237℃. MS m / z: 163 (M + ); IR (KBr): 3214, 1652, 1504, 1397, 1290, 1253, 949, 815, 779cm -1 ; 1 HNMRδ: 2.34~2.49(2H), 2.74~2.78(2H), 6.52~6.66(3H), 8.90(1H), 9.70(1H)ppm.

Embodiment 3

[0027] Example 3 Preparation of 7-hydroxy-3,4-dihydro-2(1H)-quinolinone

[0028] In a 150mL three-necked flask, add 10.9g (0.1mol) of m-hydroxyaniline, 109g of the gemini surfactant prepared by the method in Example 1, and 12.7g (0.1mol) of propionyl chloride, and stir and react at 130°C for 12 hours. Other operations are the same In Example 2, 13.7 g of white solid was obtained, namely 7-hydroxy-3,4-dihydro-2(1H)-quinolinone, the yield was 84%, m.p.228-230°C. MS m / z: 163 (M + ); IR (KBr): 3279, 1657, 1605, 1523, 1397, 1192, 866, 837, 805cm -1 . 1 HNMRδ: 2.39(2H), 2.73(2H), 6.3(2H), 6.9(1H), 9.24(1H), 9.93(1H) ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com