Short-cut denitrification process adopting catalytic iron and biological coupling

A technology for catalyzing iron and biology, applied in anaerobic digestion and other directions, can solve problems such as increasing operating costs, and achieve the effect of reducing energy consumption, strong advantages, and saving carbon sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

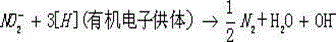

Method used

Image

Examples

Embodiment 1

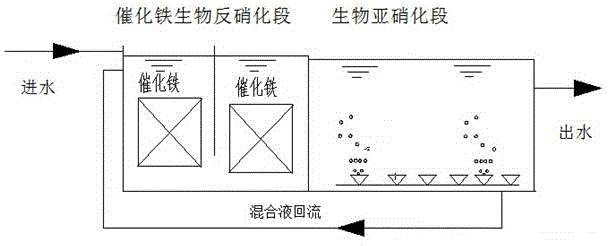

[0051] Example 1 High C / N Ratio Sewage

[0052] A city sewage BOD 5 / TKN is 5, which theoretically meets the carbon source requirements for biological denitrification and denitrification, but due to the increase in water volume, the reactor operation is overloaded, the residence time of the denitrification section is 0.5 hours, and the residence time of the nitrification section is 6.0 hours. not ideal.

[0053] Implement technique of the present invention: catalytic iron puts denitrification section, bulk density is 100kg / M 3 . When the influent total nitrogen is 30 mg / L, ammonia nitrogen is 20 mg / L, BOD 5 When the pH is 150 mg / L and the pH is 7.0, a catalytic iron short-range denitrification system is formed after domestication. The ORP of the denitrification section is controlled at –80 mV, the ORP of the nitrification section is controlled at 60-100 mV, and the dissolved oxygen is controlled at 0.5-1.0 mg / Between L. After treatment, the effluent total nitrogen is 10 ...

Embodiment 2

[0054] C / N ratio sewage in embodiment 2

[0055] A city sewage BOD 5 The / TKN is 2.5, which theoretically does not meet the carbon source requirements for biological denitrification and denitrification. The residence time of the denitrification section is 2.0 hours, and the residence time of the nitrification section is 8.0 hours. The effect of biological denitrification is not ideal.

[0056] The process of the present invention: the catalytic iron is placed in the denitrification section, and the bulk density is 50kg / M 3 . When the influent total nitrogen is 60 mg / L, ammonia nitrogen is 40 mg / L, BOD 5 When the pH is 150 mg / L and the pH is 7.2, a catalytic iron short-range denitrification system is formed after domestication. The ORP of the denitrification section is controlled at –100 mV, the ORP of the nitrification section is controlled at 60-100 mV, and the dissolved oxygen is controlled at 0.5-1.0 mg / Between L. After treatment, the effluent total nitrogen is 8 mg / L,...

Embodiment 3

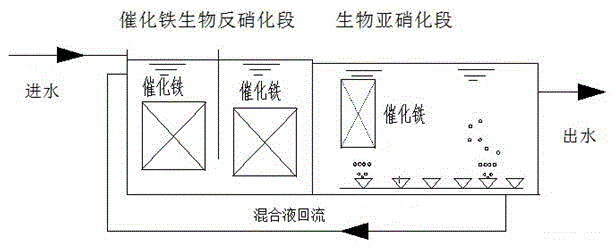

[0057] Example 3 Low C / N Ratio Sewage

[0058] A city sewage BOD 5 The / TKN is 1, which is far from meeting the carbon source requirements for biological denitrification and denitrification. Using the short-range denitrification process coupled with catalytic iron and biology of the present invention, the residence time of the denitrification section is designed to be 1.0 hours, and the residence time of the nitrification section is 7.0 hours. The catalytic iron device is placed in the denitrification section, and the bulk density is 100kg / M 3 , the first 1 / 7 of the nitrification section (residence time 1 hour) is also equipped with a catalytic iron device, and the bulk density is 200kg / M 3 . When the influent total nitrogen is 60 mg / L, ammonia nitrogen is 30 mg / L, BOD 5 When the pH is 60 mg / L and the pH is 7.2, the catalytic iron short-range denitrification system is formed after domestication, the ORP of the denitrification section is controlled at -120 mV, the ORP of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com