Culture method of AOB-ANAMMOX granular sludge

A technology of granular sludge and cultivation method, which is applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc., can solve the problem of unsatisfactory denitrification effect of domestic sewage and insufficient nitrite nitrogen content. Satisfy other problems, achieve good settlement performance, strong resistance to hydraulic shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

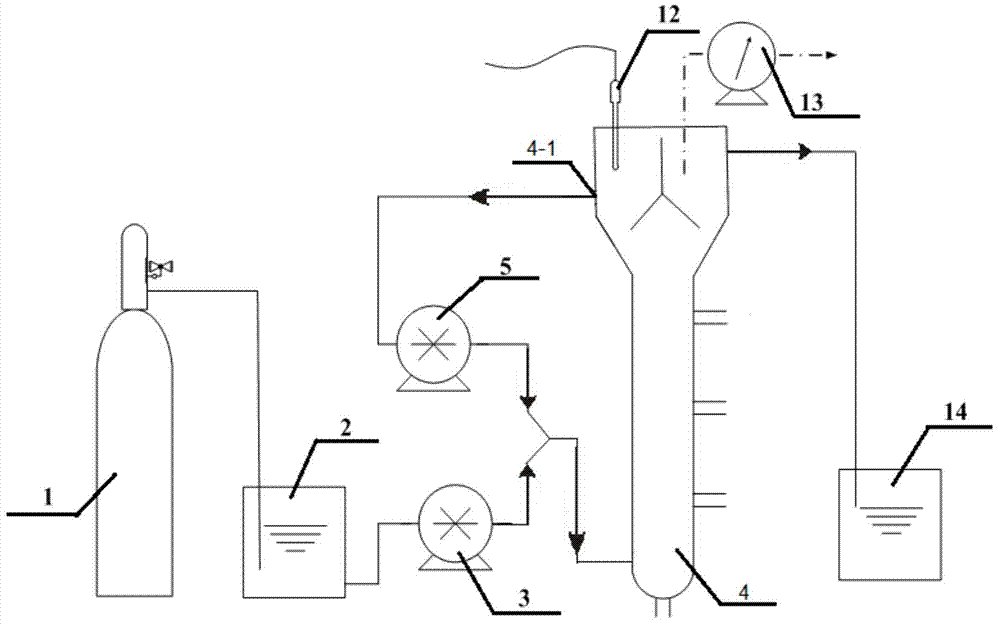

[0030] Specific implementation mode one: combine figure 1 Describe this embodiment, the AOB-ANAMMOX granular sludge of this embodiment is cultivated according to the following steps:

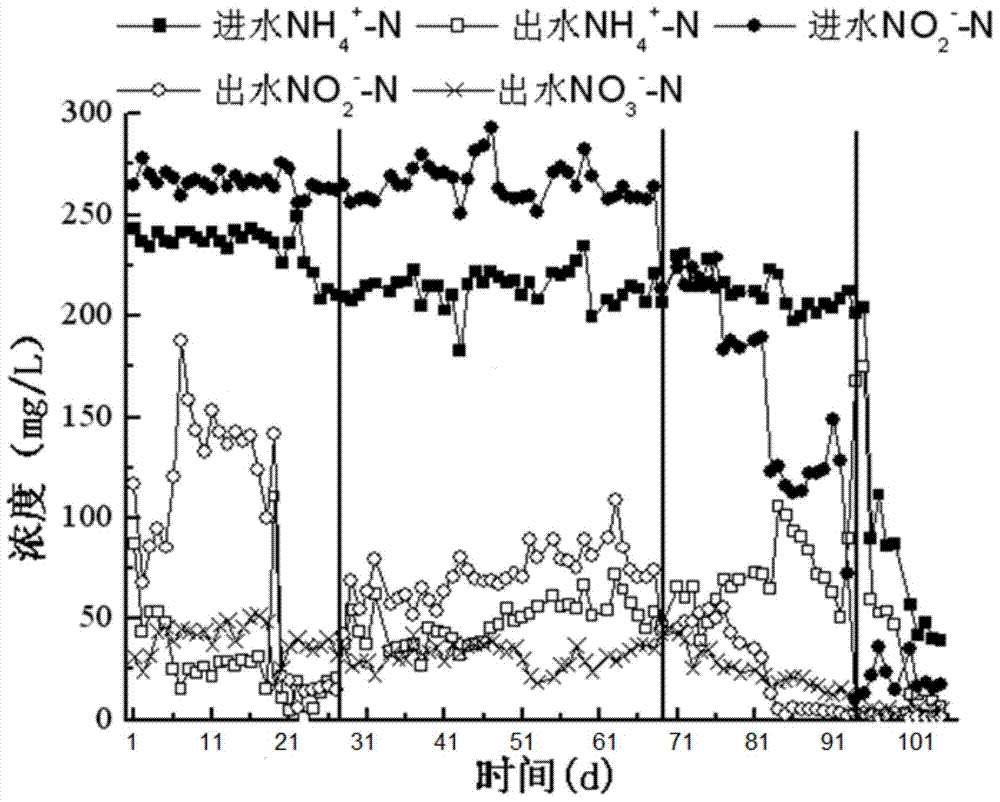

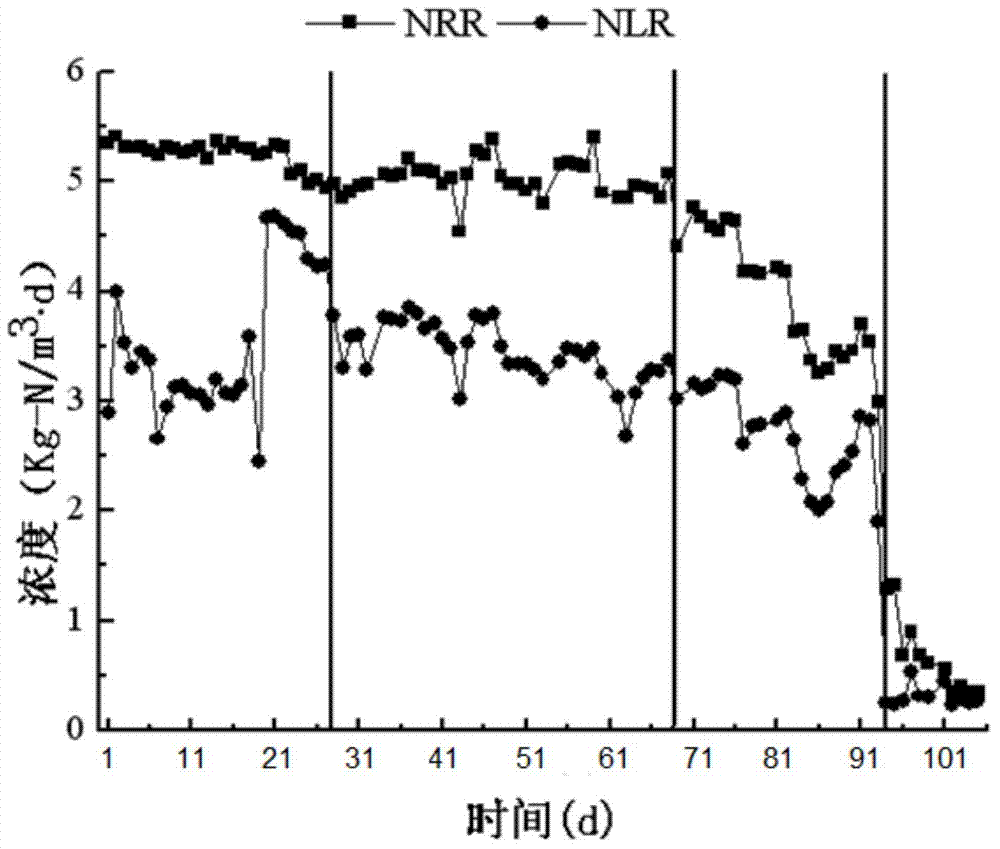

[0031] 1. Add ANAMMOX granular sludge into the EGSB reactor, and then feed nitrogen-containing simulated wastewater, and aerate the nitrogen-containing simulated wastewater with nitrogen to gradually reduce the dissolved oxygen concentration of the influent to 1.0mg / L within 24 hours; at a temperature of 33±2 ℃, the hydraulic retention time is 2.3h, and the rising flow rate in the EGSB reactor is 7m / h, cultivated for 26-28 days;

[0032] 2. Perform micro-oxygen aeration on nitrogen-containing simulated wastewater entering the EGSB reactor, and control the dissolved oxygen concentration to 1.2±0.3mg / L; at a temperature of 33±2°C and a hydraulic retention time of 2.3h, the rise in the EGSB reactor Cultivate for 41 to 43 days under the condition of a flow rate of 7m / h;

[0033] 3. Perform micro-...

specific Embodiment approach 2

[0044] Specific embodiment two: the difference between this embodiment and specific embodiment one is: NH in nitrogen-containing simulated wastewater 4 The concentration of Cl is 97.5~900mg / L, NaNO 2 The concentration is 127.7~1352mg / L, KHCO 3 The concentration is 1000mg / L, KH 2 PO 4 The concentration is 50mg / L, MgSO 4 ·7H 2 The concentration of O is 200mg / L, CaCl 2 2H 2 The concentration of O is 151mg / L, the concentration of vitamins is 0.25ml / L, and the concentration of trace elements is 0.31ml / L. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0045] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the effective volume of EGSB reactor 4 in step one is 1.53L, and the volume of reaction zone is 1L, and the volume of precipitation zone is 0.53L, anaerobic ammonia The amount of oxidized granular sludge added is 200-300mL. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com